SMT / PCB Products and Services

SMT, PCB Manufacturing products and services offered by SMTnet members.

This product does not exist or has been removed.

Browse other electronics manufacturing products.

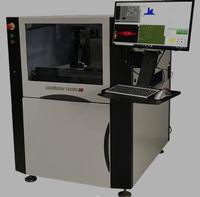

ASC International SPI or AOI (Oldest SPI Company)

AOI: VisionPro Falcon Plus (Inline), VisionPro Merlin Ultra (Batch). VisionPro Merlin (Batch) SPI/AOI Combo: LineMaster Fusion DMi (Batch) SPI: LineMaster Fusion 3D (Inline), VisionPro HSI (Batch)...

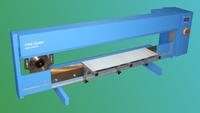

PROMATION Conveyors: "The Best Conveyors on the Planet"

PROMATION Board Handling/Conveyors: "The Best Conveyors on the Planet"...

ASSCON Vapor Phase Soldering

ASSCON Vapor Phase Soldering: ASSCON VP2100 Vacuum, ASSCON VP800 Vacuum, ASSCON VP6000 Vacuum & ASSCON VP7000 Vacuum...

kolb Cleaning Technology

Product cleaning in electronics production Product cleaning is the cleaning of highly sensitive components and is an integrated part of the value-added chain. This includes the cleaning of assembled PCBs, hybrids, DCBs, and mispr...

Mirtec SPI or AOI (Florida Customers Only)

Mirtec SPI or AOI (Florida Customers Only) 3D AOI: MV-3 OMNI, MV-6 OMNI, MV-7 OMNI & MV-9 OMNI 2D/3D AOI; MV-3 & MV-6e 3D SPI: MS-11e, MS-11 & MS-15...

MP elektronik Dry Cabinets

MP elektronik Dry Cabinets Check here https://atekllc.com/product-category/dry-storage-cabinents/...

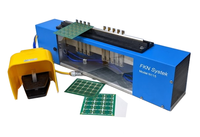

GETECH Depaneling & Label Marking

GETECH Depaneling & Label Marking Stand Alone or Inline - check website for many options https://atekllc.com/product-category/automation-depaneling/...

Parker SMT - Your #1 Worldwide Supplier for Used Equipment for PCBA. Buying and Selling your SMT or ICT equipment.

Tampa, Florida, USA

Pillarhouse - Entry level selective soldering The Pilot

To see more visit Pillarhouse here: https://www.pillarhouse.co.uk/products/selective-soldering-handload/pilot-handload Economical, compact, single point selective soldering system The all-new ultra-low-cost Pilot machine has be...

Pillarhouse Jade MKII

To see more about the Jade MKII Single Point Selective Soldering System visit Pillarhouse USA at: https://www.pillarhouse.co.uk/products/selective-soldering-handload/jade-mkii-handload Entry-level, single point selective soldering system...

Smart Factory 1.0

Smart Factory 1.0 The Pillarhouse Smart Factory 1.0 implementation allows a customer to monitor the performance of all their Pillarhouse Selective Soldering Systems. This can be across a single production line, a production facili...

Pillarhouse PillarGEN 30/40/80 Nitrogen Generator

Cost effective Nitrogen generating systems The PillarGEN Nitrogen generation system has been specifically designed to meet the Nitrogen supply requirements of the current range of Pillarhouse selective soldering systems. The latest...

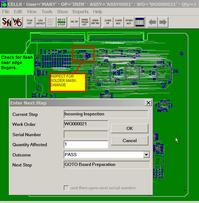

Barcodes and Board Traceability

Barcodes and Board Traceability Allows automatic process program selection and board traceability, both locally and remotely. Notes Currently supported barcode readers include: Symbol – DS6700, LS2208...

Pillarhouse Jade Handex

Designed to meet the needs of lean manufacturing, the Jade Handex offers high-speed flexible throughput at minimal cost. The Jade Handex is equipped with a revolutionary twin PCB rotary table transport system to allow simultaneous load/unl...

Pillarhouse Jade MKIV

Enhanced, entry-level, single point selective soldering system With all the proven features of the Jade MKII, the Jade MKIV sets even higher standards of performance. Designed to meet the needs of the small/medium batch manufac...

Pillarhouse Orissa Fusion

High speed, in-line, multi-platform selective soldering system Incorporating high-speed PCB transfer, the Orissa Fusion platform offers the ultimate in flexibility, coupled with reduced line length at a lower cost compared to current mar...

Pillarhouse Jade Pro

Ultra-flexible, offline, multi-platform selective soldering system Designed to meet the needs of the small batch manufacturer who requires high levels of production flexibility. The Jade Pro offers the ability to regularly change solder...

PillarDOT

Simple drop-jet fluid deposition system The Pillarhouse Drop-Jet head can be used to spray fluids at any angle in either upward or downward directions. With its patented easy bleed and cleaning feature it is ideal for automation...

Selective soldering machine - Entry level

Entry-level, single point selective soldering system Designed to meet the needs of the small/medium batch manufacturer who requires high levels of production flexibility, the Jade MKll entry-level system offers uncompromised selective so...

Pillarhouse Jade Prodex

Ultra-flexible, offline, multi-platform, quick load twin PCB rotary table selective soldering system Designed to meet the needs of the small batch manufacturer who requires high levels of production flexibility. The Jade Prodex offers th...

Pillarhouse Quadron (PLC)

High specification, bench top rotary table soldering machine A versatile four station rotary bench top soldering machine, ideally suited for high or low volume production, the Quadron combines well proven pumped soldering techniques with...

Pillarhouse Orissa Synchrodex

Flexible, in-line, modular selective soldering system Designed as a modular system, the Synchrodex range of in-line equipment offers the ultimate in flexibility with the ability to upgrade to high speed throughput when multiple modules a...

Pillarhouse Orissa Fusion In-Line Selective Soldering

High speed, in-line, multi-platform selective soldering system Incorporating high-speed PCB transfer, the Orissa Fusion platform offers the ultimate in flexibility, coupled with reduced line length at a lower cost compared to current mar...

Pillarhouse Orissa Fusion

High speed, in-line, multi-platform selective soldering system Incorporating high-speed PCB transfer, the Orissa Fusion platform offers the ultimate in flexibility, coupled with reduced line length at a lower cost compared to current mar...

Quadron (PLC)

High specification, bench top rotary table soldering machine A versatile four station rotary bench top soldering machine, ideally suited for high or low volume production, the Quadron combines well proven pumped soldering techniques with...

Pillarhouse Orissa Synchrodex Pro

Enhanced, flexible, in-line, modular selective soldering system Designed as a modular system, the Synchrodex Pro range of in-line equipment offers the ultimate in flexibility with the ability to upgrade to high-speed throughput when mult...

Pillarhouse Orissa Synchrodex Combo

In-line or stand-alone fluxer/pre-heater This compact modular in-line system utilises the same design concept as the new generation Synchrodex soldering cell and offers the user significantly reduced process time when compared to using a...

PillarPAD

An offline process programming system Allows easy creation of flux, pre-heat and solder joints and baths Produces graphical representations of the PCB Solder nozzles shown as actual size Uses industry...

Global OEM manufacturer of selective wave soldering machines. With a world-wide install base in over 65 countries, we are a global leader in the selective soldering space. Highly customized solutions available in all industries.

Elk Grove Village, Illinois, USA

Equipment Dealer / Broker / Auctions, Manufacturer, Manufacturer's Representative, Training Provider

Lead-Free Solder Training

Blackfox’s Lead Free Soldering series minimizes the risks of conversion, and gives you the confidence to introduce lead free products and services quickly, with highest quality. The lead free certification program offers the latest requireme...

IPC Certification

IPC - Association Connecting Electronics Industries® offers globally recognized industry-traceable training and certification programs on key Electronics Industry Standards. Blackfox, founded in 1996, is the premier Worldwide Approved IPC T...

Hand Soldering Training

The purpose of these courses is to promote best manufacturing practices and enhance the individual’s job performance. These courses are indispensable for everyone involved in Electronics Manufacturing. Blackfox is widely recognized in the...

PRO-STD-001 Certification

Course for Counterfeit Component Detection and Prevention Blackfox and ProSkill CTG offers a unique and comprehensive course; PRO-STD-001 Certification, a meaningful Course for Counterfeit Component Detection and Prevention. Have your...

Blackfox Training Institute, LLC

Blackfox is the industry leader in providing IPC Certifications, Solder Training, Customized Training Programs, and Counterfeit Component Training and Certification.

Longmont, Colorado, USA

Consultant / Service Provider, Manufacturer, Standards Setting / Certification, Training Provider

PCB Magazine Unloader Destacker With LED Three Color Work Indicator

Automatic Unloader & Destacker 1. Mitsubishi PLC control system 2. LED three-color work indicator, man-machine touch screen operation interface. 3. Pass through function. 4. C...

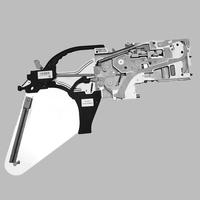

Samsung Hanwha SME 8mm Electric Feeder for SM481 SM482 Machine

Samsung SME Feeder is used for Samsung SMT pick and place machines, including SM471, SM481, SM482, SM471Plus, SM481Plus, SM482Plus, DECAN S2/F2/L2, EXCEN PRO and so on.. Samsung SME series of original new / original u...

Siemens Feeder

We have many Siemens feeder in stocks,Original used,If you have interest,you can contact us,Thanks zoey@jinchensmt.com Skype:zoeysmt Siemens 00141098 3*8 FEEDER Siemens 00141098 3*8 FEEDER Siemens 00141099...

Panasonic KME CM402/602 machines feeder, MSF,HT,BM machines feeder

Panasonic KME CM402/602 machines feeder, MSF,HT,BM machines feeder 8mm Tape Feeder KXFW1KS5A00 with sensor 8mm TapeFeeder KXFW1KSBA00 without sensor, 12/16mm Tape Feeder KXFW1KS6A00 with sensor, 24/32mm Tap...

JUKI AF/CF/FF/CF/CN ect JUKI feeders

We have original new and original used, copy new JUKI machine feeder ,If you have interest,you can contact us thanks zoey@jinchensmt.com AQ02HP Feeder 0402 8mm CF03HP Feeder 0603 8mm...

YAMAHA CL/FS/FT/FV/SS Smt Feeder

We Sell YAMAHA CL/FS/FT/FV/SS Smt Machine Feeder,original new,original used and copy new If you have interest please contact us,Thanks sale@jinchensmt.com YAMAHA:FEEDER CL8X2 (0402) PART No:KW1-M1300-00X...

KXFOE1LXAOO CM402

KXFOE1LXAOO CM402 if you have interested,please contact us. thanks zoey@jinchensmt.com...

Compact Design PCB Magazine Unloader , Pcb Destacker Machine UC-460W-BN

Automatic Unloader & Destacker UC-460W-BN 1. Panasonic PLC control system 2. LED three-color work indicator, man-machine touch screen operation interface. 3. Pass through function....

SMT PCB Handling Equipment , Pcb Loader Unloader For Circuit

ML Automatic Unloader Advantage 1. Mitsubishi(Panasonic) PLC control system 2. LED three-color work indicator, man-machine touch screen operation interface. 3. Pa...

Samsung hanwha SM482 machine

Samsung hanwha SM482 machine Any interest,please ask me zoey@jinchensmt.com...

4 PITCH PCB Magazine Unloader Humanization Design , Special Aluminum Alloy Mechanism

Full Automatic Unloader 1. Special aluminum alloy mechanism, more clearly understand MAGAZINE operation state. 2. Stable casting platform structure design, improve the stability of the equipment....

NG&OK PCB Magazine Unloader NL-M-TN With Panasonic PLC Control

Automatic NG&OK Unloader NL-M-TN 1. Structure: special aluminum alloy sheet metal combination 2. Operation: Weilun Tongtai man-machine operation key surface. 3. The control system: Pana...

Unloader Automatic Unloader DL-M-TN For PCB Assembly Line

Automatic Double Track Unloader DL-M-TN 1. PLC control system 2. Special aluminum alloy plus sheet metal combination, a better understanding of MAGAZINE operating status. 3. Double entry ra...

Samsung Smt Feeder CP and SM type

We have Samsung CP and SM Machine Smt feeder(original new ,original used and copy ne),If you have interest please contact us,Thanks Samsung CP 8*2mm Feeder Samsung CP 8*4mm Feeder Samsung CP 12mm Feeder...

YAMAHA JUKI Samsung I-pulse siemens Smt Stick Feeder

We Sell Smt Stick Feeder YAMAHA Stick Feeder JUKI Stick Feeder Samsung Stick Feeder I-pulse Stick Feeder siemens Stick Feeder, If you have interest please contact us,Thanks zoey...

SMT Nozzle Cleaning Drying Machine

Parameters of machine: Size: (L*W*H) 520mm × 450mm× 620mm Power(three phase two wire ) 2P2W,220VAC ,50/60Hz...

I-Pulse Feeder F1 and PS type Feeder

We support I-Pulse Feeder, F1 and PS type Feeder, If you have interesting, Please feel free to contact us, thanks zoey@jinchensmt.com I-Pulse Feeder F1-82-1005 Feeder LG4-M2A00-00 I-Pulse Feeder F1-84 0402 Feeder...

Samsung hanwha SM471 machine

Samsung hanwha SM471 machine Any interest,please ask me zoey@jinchensmt.com...

Automatic Clean Lead Free Solder Paste Heater

SMT Production Line Usage Automatic No Clean Lead Free Solder Paste Heater Type: Thawing machine Power Source: Electric Dimension(L*W*H): L500 x W300cm x H230mm Weight: 15KG ...

SMT Solder Paste Mixer

Input voltage 220V Work ability At the same time 1 bottle or 2 bottles of mixed soider paste...

Jinchen Electric Technology Co,.Ltd

We are please to introduce ourself- ,who is one of the SMT solution provider for Global customers, we can supply Automatic Insertion machines spare parts, SMT spare parts, (including feeder ,Nozzle,PCB

Dongguan, Guangdong, China

1809 MK5 - Heller 고급 인라인 무보이드 / 진공 리플로우 솔더링 오븐

9개 존을 갖춘 무보이드 진공 리플로우 솔더링 오븐. 균형적 흐름 기술이 있는 무보이드 / 진공 리플로우 솔더링 질소 시스템 9개의 탑 및 바텀 가열 존 - 업계 최고의 직선형 피트당 최고의 존 수! 100인치 가열 길이 - 고처리율 제공! 2개의 내부...

고처리율 애플리케이션을 위한 세계 최고의 SMT 컨벡션 리플로우 오븐 - Mark7

뉴 MK7 플랫폼이 새롭고 획기적인 여러 디자인으로 리플로우 업계를 혁신하고 있습니다! MK7은 보다 낮은 델타 T, 질소 소비 절감 및 전체 생산 플로어의 관찰이 쉽도록 하는 새로운 저고 패키지로 PM 확장에 대한 모든 고객의 요청이 통합되어 있습니다. 생산을 위한 MK7의 강력한 장점을 직접 확인할 수 있도록 당사의 세 곳 중 어느 곳이든 방문해 프로파일을 수행하고 데이터를 수집해 보실 수...

Heller VCO 755 인라인, 지속적 큐어, 수직형 포맷 미니 큐어링 오븐

큐어링 에폭시의 수직형 자동화를 위한 소형 큐어링 오븐. 생산성 향상, 품질 개선, 비용 절감은...Heller의 수직형 포맷 큐어링 솔루션과 함께. 에폭시 큐어 공정의 인라인, 수직형 자동화가 세 분야에서 즉각적이고 상당한 혜택을 제공합니다....

1936/2043 Mark 5 – 리플로우 오븐 시스템

가장 빠른 픽앤플레이스 시스템을 제공하는 분당 1.4M의 최대 벨트 속도를 갖춘 최강의 대량 리플로우 오븐 시스템. 무납 인증! 유지관리 불필요! 최저의 질소 & 전기 사용! 무료로 제공되는 통합 Cpk 소프트웨어!...

대량 생산을 위한 컨벡션 리플로우 오븐. - 1826 Mark 5

세계 최고의 컨벡션 리플로우 오븐 대량의 요구에도 일관된 성능을 제공하는 동시에, 예방적 유지관리와 바닥면적은 최소화합니다 무납 인증! 유지관리 불필요! 최저의 질소 & 전기 사용! 무료로 제공되는 통...

무플럭스 리플로우 솔더링을 위한 포름산 리플로우 오븐 - 1936 MKV

포름산 증기에서의 무플럭스 포름산 리플로우 Heller는 포름산 증기를 위한 수평형 무플럭스 포름산 리플로우 오븐을 설계해 생산에 활용할 수 있도록 제작했습니다. 이 새로운 오븐은 세미(Semi) S2/S8 안전성 표준(유독가스 포함)에 적합하도록 설계되었습니다. 포름산은 무플럭스 솔더 리플로우에서 효과적인 환원제로 보여져 왔습니다...

860 가압 큐어링 오븐(PCO)

다이 어태치 및 언더필 가압 큐어링 오븐 가압 큐어링 오븐(PCO) 또는 오토클레이브는 일반적으로 다이 어태치 및 언더필 애플리케이션에서 사용되는 접착 공정에서 보이드를 최소화하고 접착강도를 증대시키기 위해 사용됩니다. PCO pressurizes air into a rigid vessel and heats & coo...

듀얼 레인 / 이중 온도 리플로우 오븐 - 1910 MK5

듀얼 챔버 모듈 - 듀얼 챔버 + 듀얼 블로어 + 듀얼 히터 + 듀얼 T/C 두 갈래로 나뉘어진 듀얼 레인 / 이중 온도 리플로우 오븐 챔버가 동일 리플로우 오븐 풋프린트에서 2개의 다른 열 프로파일이 동시에 운행될 수 있도록 합니다. 두 갈래로 나뉘어진(듀얼) 기능...

Heller 788 인라인, 지속적 큐어, 수직형 포맷 오븐

생산성 향상, 품질 개선, 비용 절감은...Heller의 수직형 포맷 큐어링 솔루션과 함께. 에폭시 큐어 공정의 인라인, 수직형 자동화가 세 분야에서 즉각적이고 유의미한 혜택을 제공합니다. 인라인 자동화는 배치 오븐의 적재 및 하적에 필요한 노동을 없애 생산성을 증대합니다. 이는 배치 오븐 도...

-세계 최고 품질의 대류열풍방식으로 새로운 표준을 선도하는 HELLER Reflow Oven -10년 연속 World Wide Market Share 1위와 2014 SERVICE EXCELLENCE AWARDS 수상

Kyungki-Do, Kyonggi-do, South Korea

AOI - Xray - Paste Inspection

AOI - Xray - Paste Inspection - Yestech, Viscom, Omron, MVP, Cyber Optics, GSI Lumonics AOI-Xray-Paste Inspection for sale at JMW Enterprises....

PCB Magazines

PCB Magazines - CAB, NIX, Simplimatic PCB Magazines for sale at JMW Enterprises....

Parts Prep - Wire Strippers

Parts Prep - Wire Strippers - Hepco, GPD, Heller, Eubanks, Vtek Parts Prep-Wire Strippers for sale at JMW Enterprises....

Batch - Inline - Stencil Cleaners

Batch - Inline - Stencil Cleaners - Speedline Electrovert, Trek, Stoelting, Unit Design, Aqueous Technologies, EMC, Smart Sonic Batch-Inline-Stencil Cleaners for sale at JMW Enterprises...

Rework Stations

Rework Stations - Air Vac, SRT, Pace, Metcal, Conceptronic Rework Stations for sale at JMW Enterprises....

SMT Adhesive Dispensers

SMT Adhesive Dispensers - Camalot, Nordson, Asymtek SMT Adhesive Dispensers for sale at JMW Enterprises....

Through Hole Machines

Through Hole Machines - Universal, Amistar Through Hole Machines for sale at JMW Enterprises....

SMT Spare Parts

SMT Spare Parts - Electrovert, DEK, MPM SMT Spare Parts for sale at JMW Enterprises....

Wave Soldering Machines

Wave Soldering Machines - Speedline Electrovert, Vitronics Soltec, Technical Devices, Ersa, Seho Wave Soldering Machines for sale at JMW Enterprises....

Routers - Depanelizers

Routers - Depanelizers - Cencorp, JOT Routers-Depanelizers for sale at JMW Enterprises....

Used SMT Screen Printers

SMT Screen Printers - DEK, MPM, Ekra SMT Screen Printers for sale at JMW Enterprises....

SMT Conveyors

SMT Conveyors - Conveyor Technologies, JOT, Simplimatic, ASYS, Flexlink SMT Conveyors for sale at JMW Enterprises....

SMT Feeders

SMT Feeders - Fuji, Siemens, Hover Davis, Mydata SMT Feeders for sale at JMW Enterprises....

Selective Soldering Machines

Selective Soldering Machines - Pillarhouse, Vitronics Soltec, ERSA, A.C.E. Production Technologies Selective Soldering Machines for sale at JMW Enterprises....

SMT Placement Machines

SMT Placement Machines - Fuji, Mydata, Universal SMT Placement Machines for sale at JMW Enterprises....

Reflow Ovens

Reflow Ovens - BTU, Electrovert, Heller, Vitronics Soltec Reflow Ovens for sale at JMW Enterprises....

.jpg)

Buyer, Seller, Broker of Electronic Assembly Equipment

Rushford, Minnesota, USA

ETA SMT PCB Stacker/Destacker

ETA SMT PCB Stacker/Destacker If you could not find any similar items you want, you may send some photos to us. because our catalog and website haven't included all of our products....

SMT Reflow Ovens for PCB Soldering

SMT Reflow Ovens for PCB Soldering...

Online Selective Wave Soldering Machines: The Perfect Solution for High-Precision Soldering

On-line DIP Selective Wave Soldering Machine Our online selective wave soldering machines are the perfect solution for businesses that need to perform high-precision soldering on PCB assemblies. Our machines use a unique w...

Yamaha YSM20WR Modular SMT Placement

Yamaha YSM20WR Modular SMT Placement ❙ Features of Yamaha YSM20R High-efficiency modular Yamaha SMT...

SMT LED Dual Rails Reflow Soldering Machine

SMT LED Dual Rails Reflow Soldering Machine ❙ Introduce of Reflow Soldering Oven...

Good Price SMT Reflow Soldering Machine

Good Price SMT Reflow Soldering Machine ❙ Introduce of Reflow Soldering Oven...

Hot Air Reflow Solder Oven with 10 Zones

Hot Air Reflow Solder Oven with 10 Zones...

High-end Soldering Oven SMD

High-end Soldering Oven SMD ❙ Introduce of Reflow Soldering Oven...

SMT Offline X-ray X-7200

SMT Offline X-ray X-7200 Products Introduction | I.C.T Group www.smt11.com www.smtfactory.com Full SMT Factory Solution Partner SMT Offline X-ray X-7200 Introduce: I.C.T X-7200 inspection machin...

LED Reflow Oven for 3W High Power LED

LED reflow oven for 3W high power LED E10 Main product: Reflow oven with 10 zones, hot air reflow oven, SMT equipment, PCB Assembly Equipment, PCB Assembly Equipment, SMD/SMT Assembly, SMT assemb...

Good Price Reflow Oven Soldering Machine

Good Price Reflow Oven Soldering Machine...

Large Size Stable SMT PCB Lead Free Reflow Oven Machine from ETA

Large Size Stable SMT PCB Lead Free Reflow Oven Machine from ETA ❙ Introduce of Reflow Soldering Oven...

PCB Reflow Soldering Process

PCB Reflow Soldering Process ❙ Introduce of Reflow Soldering Oven...

High-end Customized Reflow Soldering Oven

High-end Customized Reflow Soldering Oven ❙ Introduce of Reflow Oven...

SMT Line 6 Heating Zones Reflow Oven

SMT Line 6 Heating Zones Reflow Oven ❙ Introduce of Reflow Soldering Oven...

LED Flexible Dispensing Machine - Precise and Efficient LED Manufacturing Solution

LED Flexible Dispensing Machine - Precise and Efficient LED Manufacturing Solution ❙ Introduce of Automatic Dispensing Machine Discover our LED Flexible Dispensing Machine, an advanced solut...

ETA SMT Cooling Conveyor

ETA SMT Cooling Conveyor If you could not find any similar items you want, you may send some photos to us. because our catalog and website haven't included all of our products....

JUKI RX-7R Pick & Place Machine

JUKI RX-7R Pick & Place Machine If you could not find any similar items you want, you may send some photos to us. because our catalog and website haven't included allof our...

Panasonic NPM X-series SMT Placement Machine

Panasonic NPM X-series SMT Placement Machine If you could not find any similar items you want, you may send some photos to us. because our catalog and website haven't included allof...

High Reliability Radiator Reflow Soldering Ovens

High Reliability Radiator Reflow Soldering Ovens ❙ Introduce of Reflow Oven&l...

I.C.T ( Dongguan ICT Technology Co., Ltd. )

I.C.T is a manufacturer from China that offers SMT, DIP, PCBA conformal coating equipment and turnkey solution.

Dongguan, Guangdong, China

Mirae SMT Nozzles, Tooling, & Consumables

We offer a wide selection of the Mirae SMT Nozzles, Tooling, & Consumables. We also offer custom engineering to standard nozzles for odd shaped components. Count On Tools has been a manufacturer of high quality,...

Mycronic Mydata SMT Nozzles, Tooling, & Consumables (Midas & Hydra)

The new series of Mydata replacement nozzles, for both the Midas and Hydra mountheads, are the only direct replacement for OEM nozzles on the market. We also offer custom engineering to standar...

LED Nozzles

Recent growth in LED technology and solid state lighting has provided the electronics manufacturing industry with viable solutions for today's electronic devices. As a result, companies in the surface mount technology (SMT) industry are expanding...

Quad / PPM SMT Nozzles, Tooling, & Consumables

We offer a wide selection of the Quad/PPM SMT Nozzles, Tooling, & Consumables. We also offer custom engineering to standard nozzles for odd shaped components. Count On Tools has been a manufacturer of high qualit...

Yamaha SMT Nozzles, Tooling, & Consumables (YV, YG, YS, & more)

We offer a wide selection of the Yamaha SMT Nozzles, Tooling, & Consumables. We also offer custom engineering to standard nozzles for odd shaped components. Count On Tools has been a manufacturer of high quality,...

Mycronic / Mydata Feeder Repair Service

Count On Tools now offers repair services for MYDATA Agilis Feeders. This program will be available for the 3.7, 4.0, 4.7, and 5.4 Agilis feeders. This is the only repair option for these feeders on the market and provides significant costs sav...

Selective Soldering Nozzles & Tooling (Ace KISS, Pillarhouse, RPS, & more)

Count On Tools has been a manufacturer of high quality, low cost nozzles and associated components for the SMT & PCB Assembly industries for over 20 years. Our commitment and goal is to be the number one supplier of precision engineered SMT no...

Assembleon SMT Nozzles, Tooling, & Consumables (Emerald, Opal, Topax, Saphire, MC, MG, & more)

We offer a wide selection of the Assembleon SMT Nozzles, Tooling, & Consumables. We also offer custom engineering to standard nozzles for odd shaped components. Count On Tools has been a manufacturer of high qual...

Custom Engineered SMT Nozzles & Tooling

Effective Solutions for any Odd-Form Application on any OEM Platform. Count On Tools has the experience and manufacturing flexibility to be able to develop custom engineered solutions to satisfy your individual Proc...

Hitachi SMT Nozzles, Tooling, & Consumables (Sigma, GXH, & more)

We offer a wide selection of the Hitachi SMT Nozzles, Tooling, & Consumables. We also offer custom engineering to standard nozzles for odd shaped components. Count On Tools has been a manufacturer of high quality...

ezLOAD PCB Support System

Board Handling - Pallets, Carriers, Fixtures

Count On Tools Inc., a leading provider of precision components and SMT spare parts, introduces the new ezLOAD PCB Support System. With the recent increase of densely populated double-sided circuit boards, COT recognized the need for more affordab...

Custom LED Nozzles & Pick Up Tools

Count On Tools specializes in custom engineered nozzles for all types of LEDs (Cree, Luxeon, Phillips, NIchia, Osram, etc). Recent growth in LED technology and solid state lighting has provided the electronics manufa...

Juki SMT Nozzles, Tooling, & Consumables (KE, FX, JX, RX, & more)

We offer a wide selection of the Juki SMT Nozzles, Tooling, & Consumables. We also offer custom engineering to standard nozzles for odd shaped components. Count On Tools has been a manufacturer of high quality, l...

Universal SMT Nozzles, Tooling, & Consumables

We offer a wide selection of the Universal SMT Nozzles, Tooling, & Consumables. We also offer custom engineering to standard nozzles for odd shaped components. Count On Tools has been a manufacturer of high quali...

INSTOCK Consigment Program for SMT Nozzles, Tooling, & Consumables

The INSTOCK Consignment Plus Program has been developed to give EMS companies and contract manufacturers immediate access to project critical products with no up-front inventory costs or risk of overstock. INSTOCK program serves particip...

ezCLIP Universal Stop Clip for PCB Magazine Racks

Introducing the ezCLIP universal stop clip for PCB magazine racks. The ezCLIP system was created to allow electronics manufacturers who manually load/unload PCB magazine racks a simple way to distinguish required spacing between boards and to p...

Fuji Nozzles (NXT, XP, CP-6, CP-7, QP3, IP3, & more)

We offer a wide selection of the Fuji SMT Nozzles, Tooling, & Consumables. We also offer custom engineering to standard nozzles for odd shaped components. Count On Tools has been a manufactu...

StripFeeders Adjustable Feeder System

Why purchase expensive feeders for each component when you only need to place a few at a time? Count On Tools Inc. (COT), a leading provider of precision components and SMT spare parts, introduces the revolutiona...

Panasonic SMT Nozzles, Tooling, & Consumables (CM402, CM602, NPM, MSF, BM, HT, MSR, MV, & more!)

We offer a wide selection of the PanasonicSMT Nozzles, Tooling, & Consumables. We also offer custom engineering to standard nozzles for odd shaped components. Count On Tools has been a manufacturer of high qualit...

QWIKTRAY Custom Matrix Trays for Electronic Components

Do you have a unique component that isn’t available in tape and reel? Tired of hand placing those components because you don’t have a compatible feeder? Can’t find J...

COT specializes in high quality SMT nozzles and consumables for pick and place machines. We provide special engineering design service of custom nozzles for those unique and odd components.

Gainesville, Georgia, USA

Auto Feeding And Loading Full Automatic V-cut PCB Depaneler

Full Automatic V-cut PCB Depaneler Introduction: This equipment can further improve the quality of depaneling. It can realize V-groove XY two-way automatic cutting, cutting aluminum & FR4 boards without burr, can...

V Cut PCB Depaneling Aluminum Cutter Machine For LED Printed Circuit Board

V Cut PCB Depaneling Aluminum Cutter Machine For LED Printed Circuit Board LED PCB Separator Features: 1. Separates panels up to 0.1" 2. The longest panel: No limit 3....

UV Laser PCB Depaneling System, Dual Table for High Volume

UV Laser PCB Depaneling System, Dual Table for High Volume Laser Depaneling Purpose: The processing and application objects are PCB, FPC soft and hard plate and related material cutting, c...

PCBA CNC Router Machine Automatic PCB Milling Machine

PCBA CNC Router Machine Automatic PCB Milling Machine PCBA CNC Router Machine Advantages: X10 zoom-in image makes programming easier&increase the accuracy of point setting....

600mm Penumatic V-groove PCB Cutter Linear Blades PCB Separator

600mm Penumatic V-groove PCB Cutter Linear Blades PCB Separator Penumatic V-groove PCB Cutter Description: In order to improve the output of printed circuit board (PCB) manufactur...

Metal Board V-cut PCB Depaneling Machine Guillotine PCB Cutter

Metal Board V-cut PCB Depaneling Machine Guillotine PCB Cutter Features: 1. Less stress ,high cutting quality 2. Suitable for cutting all kinds of PCB material, even for Alumin...

15W UV Laser Economic PCB Laser Depaneling System

15W UV Laser Economic PCB Laser Depaneling System PCB Laser Depaneling System Specification: Laser solid-state UV laser...

Bottom Cutting Automatic PCB Depaneling Router Machine with 3HP Vaccum Cleaner

PCB Router Function: Used for routed PCB panel singulation with lower stress. PCB Router Advantages: Lower mechanical stress Precise tooling ...

Mini Standalone PCB Depaneling Router Machine Economic PCB Separator Machine

Mini Standalone PCB Depaneling Router Machine Economic PCB Separator Machine PCB Depaneling Router Features: Smooth cutting edge Low cutting stress Manul loadi...

Inline UV PCB Laser Depaneling Machine

Inline UV PCB Laser Depaneling Machine Inline UV PCB Laser Depaneling Instruction: PCB depaneling and singulation laser systems are gaining popularity—especially as circui...

Customized Die Tooling FPC PCB Punching Machine

Flexible PCB Board Cutting Machine PCB Punching Machine With Cutomized Die Tooling PCB Punching Machine Features: 1. Depaneling PCB/FPC by means of punching dies, to avoid micro-cracks cau...

LED Bench Top PCB Separator Machine Aluminum PCB Cutting Machine

LED Bench Top PCB Separator Machine For LED FR4 Aluminum PCB Boards Equipment designed to minimize board stress and avoid component damage. Three pairs of precision beveled cutting blades ensure the board does not...

2.4M Platform Aluminum LED Strip PCB Depanelizer V-cut PCB Cutting Machine

2.4M Platform Aluminum LED Strip PCB Depanelizer V-cut PCB Cutting Machine PCB Depanelizer Features: 1. Separates panels up to 0.1"...

Inline V-Cut PCB Separator Machine Multi-blade PCB Depanelizer

Inline V-Cut PCB Separator Machine Multi-blade PCB Depanelizer Inline PCB Separator Functions: 1. This machine is used for PCB board depaneling after inserter. 2. It...

Automatic V-cut PCB Depanelizer Machine

Automatic V-cut PCB Depanelizer Machine V-cut PCB Depanelizer Application: 1. Cutting Materials: Aluminum Board, PCB Board, Soft Fiber, clean and burr-free, high speed and effec...

Desktop PCB Depaneling Router Machine with Customized Fixture

Desktop PCB Depaneling Router Machine with Customized Fixture Desktop PCB Router Features: 1. Bench-top single table PCB router with speeds up to 100mm/s and positioning speeds of 500mm/s....

FPC / PCB Punching Dies PCB Depaneler For High Volume Boards Singulation

FPC / PCB Punching Dies PCB Depaneler For High Volume Boards Singulation Advantages: 1. Pneumatic, environmental protection 2. High efficiency, suitable for high volume PCBs...

Multi Blade V-Cut PCB Cutting Machine LED Strip PCB Separator

Multi Blade V-Cut PCB Cutting Machine LED Strip PCB Separator V-cut PCB Cutting Machine Features: 1. It can cut many boards with multiple sets of knives work at the same tim...

Full Automatic PCB Depaneling Router Machine PCB Separator Without Fixture

Full Automatic PCB Depaneling Router Machine PCB Separator Without Fixture Our Service: 1. Lifetime technical support and 2 years warranty. 2. Free replacement or refund would be don...

PCB Laser Cutting Machine Laser Depaneling of Assembled PCBs/FPCs

PCB Laser Cutting Machine Laser Depaneling of Assembled PCBs/FPCs PCB Laser Cutting Machine Advantages: 1. No mechanical stress 2. Lower tooling costs 3. Higher quality of...

Manufacturer of PCB depaneling and PCB soldering machines since 2005, products include CE approval V-groove PCB depanelizer, PCB router, PCB punching machine, laser depaneling, hot bar soldering machines and soldering robots.

Huizhou, Guangdong, China

PCB cutting machine|PCB Depaneling Router

PCB separator with high precision shaft system can move quickly for cutting or separate the PCB printed circuit board,increase productivity while maintaining high accuracy. &l...

auto vision measuring Vision Measuring Machine

auto vision measuring machine can be applied to a variety of molds, aircraft, cars, mobile phones, computers, hardware, plastics, electronics, die-cutting, screen printing, LCP film, PCB, FPC, Cover, TP, ultra-large LCD monitor and...

auto smt magazine unloader/NG OK pcb unloader from ASCEN technology

auto smt magazine unloader/NG OK pcb unloader is connected to the back of AOI and has horizontal movement and go-through functions,The OK and NG PCB after being tested by AOI can be separated and sent to the PCB racks, so that the PCB can be...

PCB magazine loader SMT multi magazine loader machine

PCB magazine loader SMT multi magazine loader machine as SMT line automatic PCB magazine loader that feeds PCBs into the Process Line from Stacks or Magazines.The unit loads the production line automatically by pushing PCBA out of...

axial component De-Taping Machine

ASCEN axial component de taping machine AS-830 use for unloading tape for the taped axial component. Separation the tape of the taped axial lead component that can solve the component problem of lead length not enough.automatic...

V-cut cutting machine

V-cut cutting machine For internal strength generates during separation, Minimize it to value under 180uE ,to avoid PCB solder crack or component damage If you want know how to choose the best PCB sep...

Telescopic Gate Conveyor

Telescopic Gate Conveyor and Lower gate conveyor and PCB gate conveyor are used for creating a passage in the PCB assembly line to give the operator access to the rear of the production equipment. The integrated conveyor segment slides acros...

multi track multi magazine PCB loader unloader for NG reject PCB unloading

multi track multi magazine PCB loader unloader is used to receive PCB printed circuit board in DIP production line,After AOI machine to receive the signal given by AOI ASCEN technology co.,ltd is ...

insertion machine radial feeder

ASCEN insertion machine radial feeder use to cuts and bends taped axial components,and then holds the component so that the robot can pick them up online or link to the SMT insertion machine for robotic feeding operation....

PCB printed circuit separator

PCB printed circuit separator is used for separate the PCB board with the V-grooves. And apply for the PCB circuit board and the LED T8 tube bar separating. If you want know how to choose t...

automatic SMT pcb loader for SMT manufacturing from ASCEN technology

automatic SMT pcb loader as SMT line automatic PCB magazine loader that feeds PCBs into the Process Line from Stacks or Magazines.The unit loads the production line automatically by pushing PCBA out of a magazine onto the conveyor...

3D Vision Measuring Machine

Application: The 3D Vision Measuring Machine can be applied to a variety of molds, aircraft, cars, mobile phones, computers, hardware, plastics, electronics, die-cutting, screen printing, LCP film, PCB, FPC, Cove...

automatic PCB separator

automatic PCB separator can separate up to 20 PCBs simultaneously, it mainly use for the PCB assembly in the large mass production with the high efficiency and save a lots of labor for the manufacturer. &...

Vision Measuring Machine With Probe

Application: Vision Measuring Machine With Probe Applied mainly for 2D measurement and can support some specific 3D measurement as necessary, this instrument is a high preci...

automation face mask making machine

automation face mask making machine also known as face mask production manufacturing line,dusk mask machine,disposable face mask making machine.It is automatic output,a face mask body machine has the ear belt wel...

face mask manufacturing machine

face mask manufacturing machine also known as one to three mask production line, composed of a mask body machine and three ear band composed of welding machine. Every minute can output 120-150 piece of complete plane mask,...

SMT magazine loader

This is SMT magazine loader,PCB automatic Loader,pcb loader, pcb magazine loader, pcb auto loader as SMT line automatic magazine loader machine that feeds PCBs into the Process Line from Stacks or Magazines. ...

ASCEN-900 Multi Cutter separator/Nutzentrenne/PCBA depaneling machine/PCB depanelizer/PCB depaneling machine

ASCEN-PCB multi cutter separator applies to automatic online separate the PCB board. High efficiency multi cutter PCB depeneling machine can directly connect the reflow oven and pick and the pick and place machine...

magazine PCB loader

PCB board handling equipment for automated assembly of PCB’s. ASCEN 蓝色文字 as SMT line auto PCB loader machine that feeds PCBs into the Process Line from Stacks or Magazines....

dust mask manufacturing machine

dust mask manufacturing machine For disposable nonwoven face mask body making.Every minute can output 80-100 pieces of mask body. Normally work together with face mask earloop welding machine, face mask tie on machine, from non woven raw mat...

Manufacturer of automated production systems;PCB magazine loader,PCB separator,PCB cutting machine,PCB unloaders, PCB conveyors,PCB depaneling machines,PCB turn conveyors,PCB conformal coaters,PCB solder paste printer,PCB buffer

Dongguan, Guangdong, China

回流焊炉-Mark 7

适用于高产能的世界一流的SMT 回流焊炉 MK7系列具有多项革命性和突破性的设计。MK7系列结合客户需求,优化DELTA T,减少耗氮量,延长保养间隔时间。汇集各项优化功能的同时降低了机身高度,使视野更开阔。 HELLER欢迎您参观我们的研发中心和制造工厂,亲自在MK7的设备上做PROFILE测试,共同见证MK7系列的强大功能及优势。或者将您的产品寄给我们,我们会将PROFILE 的测试结果与您...

1910MK5- 双腔4条轨道SMT 回流焊炉

双轨及双温度回流焊炉 双炉膛模组:双炉膛+双腔吹风马达+双腔加热模组+双腔独立温度测量监测 分岔功能 双炉膛模组 双轨 双导轨和双中央支撑系统...

1936/2043 Mark 5 – 回流焊系统

以高达1.4米/分钟的高链速为适应极限贴片速度提供了高产能需求解决方案。 无铅保证 免保养 最低的耗氮与耗电 免费的一体化 CPK 软件 1936与2043 MK5系列向人们展现了最高水平的炉温均温再现性。与Mar...

Heller 788在线、连续、垂直炉烤箱

Heller提供垂直炉烤箱用以提高生产效率、质量及降低成本的解决方案 这种升降模式的固化炉利用了垂直空间,适用于固化应用,最多可达4小时的固化时间,而占地仅有96“(2.5m) 的面积。极适用于填充和封装制成。 在线式垂直炉在固化树酯的制程中有显著的三大领域...

1936 MKV - 蚁酸回流焊炉

甲酸蒸气中无助焊剂的甲酸回流炉 Heller设计并制造了可用于甲酸蒸汽水平式无助焊剂甲酸回流焊炉。这款新烤箱的设计符合Semi S2 / S8安全标准(包括有毒气体)。 已证明甲酸是无助焊剂回流中的有效还原剂 卧式回流炉中的优异结果证明晶圆凸块应用...

1826MK5 - 适用于高产能的回流焊炉

世界一流的回流焊炉 为高产能需求,最小化保养所需时间及最小占地面积提供稳定的性能 无铅保证 免保养 最低的耗氮与耗电 免费的一体化 CPK 软件 随着最新的技术突破,HE...

1809 MK5-Heller先进联机无气泡/真空回流焊炉

均衡气流技术的无气泡/真空回流焊氮气系统 9个顶部和底部加热区-业内每英尺拥有最高的区域数! 100英寸加热长度-可提供超大产量! 2个内部冷却区-提供最低的出口温度! 总长度为180英寸-优化占地面积! 带有10英寸模块的新型模块设计...

Heller 755在线连续式的垂直烘烤炉

小型化的垂直烘烤炉 Heller提供垂直炉烤箱用以提高生产效率、质量及降低成本的解决方案 在线式垂直炉在固化树酯的制程中有显著的三大领域 减少人员在生产过程中的上料及下料的时间浪费以提高生产效率 减少烤箱在开关门时所产生的温度...

860压力固化烤箱(PCO)

压力固化烤箱(PCO)或高压容器用于使空隙最小化并增加通常用于贴装附着和底部填充应用中的粘合工艺的粘合强度。 PCO将空气加压到刚性容器中,并通过强制对流加热和冷却。 加热器,热交换器和鼓风机位于压力容器内部。 固化过程完成后,压力固化炉会自动将压力降低到1atm并冷却。...

ESD Equipment

ESD Equipment For Sale Protect your sensitive PCBs with our wide selection of static control solutions. Reduce risks and costs associated with static electricity. We strive to provide the lowest cost and highest quality ESD accesories and factory s...

Feeders

We stock and trade in all type of SMT feeders. Fuji · ASM · Yamaha · Panasonic· ·Samsung · Universal· Label Feeders Vibratory Feeders Tray Feeders and Towers Feeders Fuji – Medidas: W08f, W12c, W16c, W24c, W32c, W44c, W56c, W72, W88. Feeder...

We are a global electronics manufacturing Solutions provider ....Our company supplies new and used SMT equipment, spare parts, consumibles, ESD supplies and services to a wide range of EMS companies.

Jalisco, Jalisco, Mexico

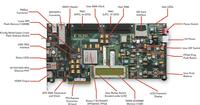

MVME51105E-2263

VME Processor Module Refurbished – Good Condition Manufacturer: Motorola Model: MVME 5100 Microprocessor: MPC7410, MPC750 or MPC755 with 32KB/32KB L1 cache DRAM: Up to 512MB of onboard ECC S...

MVME167PA-34SE

High-performance SBC Refurbished – Good Condition Manufacturer – Motorola 133 MHz MC68040 32-bit microprocessor with 8KB of cache, MMU, and FPU Full 32-bit master/slave VMEbus inter...

MVME167PA-36SE

High-performance SBC Refurbished – Good Condition Manufacturer – Motorola 133 MHz MC68040 32-bit microprocessor with 8KB of cache, MMU, and FPU Full 32-bit master/slave VMEbus inter...

MVME55006E-0163

MVME5500 Single-Board Computer Refurbished – Good Condition Manufacturer: Emerson MPC7457 PowerPC® processor at 1 GHz 512KB of on-chip L2 cache and 2MB of L3 cache AltiVec coprocessor fo...

We are your obsolete industrial product specialists. Our inventory includes VME, cPCI, ATCA, SBCs and much more industrial electronics

Hackettstown, New Jersey, USA

SMT 松下/西门子/三星/FUJI/YAMAHA/JUKI/机器销售维修

According to the customer's requirements, there are slow and fast modes of transportation, and the quotation does not include shipping fees, which are free of charge in China.(运输方式按照客户的要求,有慢的,也有快的,报价不包含运费,国内免运费。)...

我们是一家来自中国的SMT供应商。我们长期供应SMT设备供料器及设备配件,包括松下、三星、雅马哈、富士、西门子、JUKI等。我们供应SMT吸嘴、SMT供料器、SMT机器。

Suzhou, Jiangsu, China

Voidless / Vacuum Reflow Soldering Oven - 1809 MK5

1809 MK5 - Heller Advanced In-Line Vacuum Reflow Oven Nitrogen System with Balanced Flow Technology 9 Top And Bottom Heated Zones - highest zone count per linear foot in the industry!&...

860 Pressure Curing Oven (PCO)

A Pressure Cure Oven (PCO), or Autoclave, is used to minimize voiding and increase adhesion strength for bonding processes typically used in die attach and underfill applications. PCO pressurizes air into a...

Convection Reflow Oven Mk7

Convection Reflow Oven The World's Best Convection Reflow Oven for High-Throughput The New reflow oven platform revolutionizes the...

High Volume Reflow Oven - 1936/2043 Mark5

The World's Best Convection Reflow Oven The ultimate high volume production reflow oven with belt speeds up to 1.4 m/min to accommodate the fastest pick and place systems....

Flux Free Formic Acid Reflow Oven - 1936 MKV

Flux Free Formic Reflow Reflow in Formic Acid Vapor Heller has designed and built an production ready horizontal reflow oven for formic acid vapor. This new oven has been designed to...

Vertical Curing Mini Oven - Heller 755

The mini vertical oven has a cycle time of 25 - 60 seconds per 150mm fixture, 4mm Edge Hold Pins and Guides. PCBs up to 250mm wide can be processed. Dual Feed option for high throughoutput. In-line, vertical automation...

SMT Reflow Oven - 1826 Mark 5

The World's Best SMT Convection Reflow Ovens for Large Boards and Dual Lane 1826 Mark 5 reflow oven provides consistent performance for high volume reflow requirements while minimizing preventative maintenance and floorspace....

Dual Lane / Dual Temperature SMT Reflow Oven - 1910 MK5

Dual Chamber Module - Dual Chambers + Dual Blowers + Dual Heaters + Dual T/Cs. Bifurcated (Dual) chamber reflow oven allows 2 different thermal profiles to run simultaneously in the same reflow oven foot pr...

Vertical Curing Oven - Heller 788

Heller 788 In-line, Continuous Cure, Vertical Format Oven This elevator format oven utilizes vertical space to accomodate curing applications of up to 4 hours while only occupying 96" (2.5m) of fl...

Reflow ovens for automated SMT PCB assembly, specializing in lead free processing and nitrogen reflow. The best convection reflow ovens on the market.

Florham Park, New Jersey, USA

LISA Modular Handling System

Compact designed machines to match perfectly different kind of modular operation process Key configuration : Tray in - Tray out Tray...

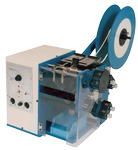

Automatic Tape & Reel

Automatic tape & reel equipment - manual tape and reel - fully automatic tape and reel including vision inspection...

TFA - Automatic Tube Feeder (TFA)

TFA - Automtatic Tube Feeder (TFA) • Basic module for 1 type of component • Cycle time : 1,5 seconds (1up feed) • Mounted on...

3D inspection machine

Compact designed machines to match perfectly different kind of modular operation process Key configuration : Tray in - Tray out...

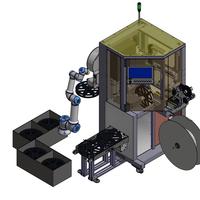

PICO Modular Pick and Place System For Tape and Reel Packaging

Modular automatic pick and place machine featuring tape and reel module, bowl feeder and tube feeeder. Ergonomic, easy access, economic and easy to use Our standard input and output modules can be located all around the...

NANO Pick & Place Modular Handling System

This machine is especially designed for multifunction operations Key configuration: Tray in - Tray out Tray in - Tape out &...

High Precision Mechanical Parts Manufacturing And Precision Dies

Milling Turning Grinding Honing EDM Wire cutting Heat Treatment Machining...

ARC - Automatic Reel Changer

Automatic Reel Changer - ARC Flexible, easy to use, menu driven software and...

ATF - Automatic Tray Feeder

ATF - Automatic Tray Feeder Flexible, easy to use, advanced mechanic...

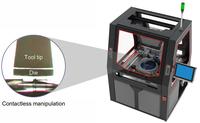

LEVIO Contactless Touchless Pick and Place

Contactless touchless manipulation, no more contact and surface defects Flexible, easy to use, menu driven software, advanced mechanic and electronic characteristics, fully contactless manipulation capabilities....

Tape & Reel Services For Standard or Non Standard SMD Components

We offer tape and reel packaging services for standard or non standard SMD components. We provide as well customized carrier tapes for special components designed at our customers specifications...

Tube Feeder Module For Any Type of SMD Components in Plastic Tubes

Basic module for 1 type of component Easy changeover kit for tube loader (1 for each component type) Tube height adjustable thanks to precision screw Maximum heig...

PICO II Pick&Place machine

New PICO II pick&place machine now available Media Input : Bulk Bowl feeder or Tube feeder Media Output : Tape & reel Vision inpsection UPH : up to 8'000 parts&...

Connector vision inspection machine

Connector vision inspection machines 2D - 3D integration Coplanarity inspection Tube or tray input Tape and reel output...

Tape & Reel Material

We supply the following material for tape & reel equipment : Pocket tape Cover tape Reels (all dimensions)...

ARC Automatic Reel Changer

Ready for Industry 4.0 ARC - Fully Automatic Reel Changer Stand alone module to be integrated on any Tape&Reel machine output Option : Automatic Sticker labelling Option...

MB872 Tape & Reel Module For Any Type of SMD Components

Reel input : Diam. 180 / 330 / 380 / 560 / 760mm (7 / 13 / 15 / 22 / 30 inches) Reel output : Diam. 180 / 330 / 380 / 560 (13 / 15 / 22 inches) Tape advance - stepper moto...

Modular pick and place automation - tape and reel - tube feeder - coplanarity check - assembly machine - contactless pick and place

St.Blaise, Switzerland

Hot Air BGA Rework Nozzle for the SRT BGA Rework Station 10mm x 42mm

SRT, VJE, VJ Electronics BGA Rework Nozzles 10mm x 42mm Hot Air Nozzle. Fits SRT Sierra Summit, 1000, 1100 , VJ Electronics and more. 1 in stock....

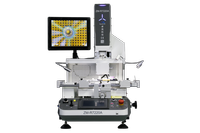

ZM-R720A BGA Rework Station

The Zhuomao ZM-R720A BGA Rework Station. Place SMD components as small as 0.2mm with this high resolution Hot Air Rework System. One of the most precise machines on the market at this affordable price. Call (888) 406-2830 for a...

Hot Air BGA Rework Nozzle for the SRT BGA Rework Station 48 X 48mm

SRT, VJE, VJ Electronics BGA Rework Nozzles 48mm x 48mm Hot Air Nozzle. Fits SRT Sierra Summit, 1000, 1100 , VJ Electronics and more....

Hot Air BGA Rework Nozzle for the SRT BGA Rework Station 19 X 19mm

SRT, VJE, VJ Electronics BGA Rework Nozzles 19mm x 19mm Hot Air Nozzle. Fits SRT Sierra Summit, 1000, 1100 , VJ Electronics and more....

Workmanship Standards & Soldering Instruction for Through-Hole Components, Wires & Terminals

An 8 hour combined lecture, video and hands on session that includes: Soldering techniques for soldering wires to terminals including through-hole components. Identify the different types of solder terminals, con...

Hot Air BGA Rework Nozzle for the SRT BGA Rework Station 35mm x 35mm

SRT, VJE, VJ Electronics BGA Rework Nozzles 35mm x 35mm Hot Air Nozzle. Fits SRT Sierra Summit, 1000, 1100 , VJ Electronics and more. 1 in stock....

ZM-R7220A BGA Rework Station

With the Zhuomao ZM-R7220A you can place SMD components as small as .2mm with this high resolution Hot Air Rework System. Features: Manual/Stationary Vision System Places components from .2mm to 60...

Hot Air BGA Rework Nozzle for the SRT BGA Rework Station 45mm x 45mm

SRT, VJE, VJ Electronics BGA Rework Nozzles 45mm x 45mm Hot Air Nozzle. Fits SRT Sierra Summit, 1000, 1100 , VJ Electronics and more. 1 in stock....

Hot Air BGA Rework Nozzle for the SRT BGA Rework Station 45mm x 45mm

SRT, VJE, VJ Electronics BGA Rework Nozzles 45mm x 45mm Hot Air Nozzle. Fits SRT Sierra Summit, 1000, 1100 , VJ Electronics and more. 1 in stock....

Hot Air BGA Rework Nozzle for the SRT BGA Rework Station 23mm x 23mm

SRT, VJE, VJ Electronics BGA Rework Nozzles 23mm x 23mm Hot Air Nozzle. Fits SRT Sierra Summit, 1000, 1100 , VJ Electronics and more. 1 in stock....

BGA Reballing Fixture, Hi Yield

Custom made reballing fixtures designed for your specific component. Allows for high yield reballing of multiple parts at one time. Use for ball attach to BGA components and for solder bumping of LGA's and QFN's. Simply s...

Hot Air BGA Rework Nozzle for the SRT BGA Rework Station 12 X 12mm

SRT, VJE, VJ Electronics BGA Rework Nozzle 12mm x 12mm Hot Air Nozzle. Fits SRT Sierra Summit, 1000, 1100 , VJ Electronics and more....

BGA Reballing Training

In this One-Day class you will learn successful techniques to re-ball BGA Components. Both Lead and Lead Free Solder Balls will be covered. The student will have an opportunity to use and evaluate some of the most popular BGA rework fi...

Solder Training and Solder Certification Courses

Solder Training and Solder Certification Courses Taught in Accordance With IPC Soldering Guidelines. We offer a variety of customized courses set up specifically for our customers requirements. An example would be our combination...

Hot Air BGA Rework Nozzle for the SRT BGA Rework Station 27mm x 27mm

SRT, VJE, VJ Electronics BGA Rework Nozzles 27mm x 27mm Hot Air Nozzle. Fits SRT Sierra Summit, 1000, 1100 , VJ Electronics and more. 1 in stock....

Hot Air BGA Rework Nozzle for the SRT BGA Rework Station 36 X 36mm

SRT, VJE, VJ Electronics BGA Rework Nozzles 36mm x 36mm Hot Air Nozzle. Fits SRT Sierra Summit, 1000, 1100 , VJ Electronics and more....

Hot Air BGA Rework Nozzle for the SRT BGA Rework Station 35mm x 35mm

SRT, VJE, VJ Electronics BGA Rework Nozzles 35mm x 35mm Hot Air Nozzle. Fits SRT Sierra Summit, 1000, 1100 , VJ Electronics and more. 1 in stock....

Flux, Tacky, Amtech

We stock Amtech and Chip Quik Tacky Fluxes and Solder Paste. Availalbe in 10cc Syringe, 75 Gram and 150 Gram Jars. Check out our on line store: https://precision-pcb-services-inc.myshopify.com/collections/all Or...

BGA Rework Services

BGA Rework Services Offered BGA Remove and Placement Level Three Pad Repair Wire Add Trace Repair BGA Re-Balling BGA Inspection We...

Hands-On, Assembly, Rework, and Solder Skills Training Seminars

This new series of Hands-On Skills Training will focus on those seeking new employment skills, skills for job advancement and companies requiring industry certification for their employees. In consideration of the current economic situation,...

Products, services, training & consulting for the assembly, rework & repair of electronic assemblies. BGA process experts. Manufacturers Rep, Distributor & Service Provider for Seamark/Zhuomao and Shuttle Star BGA Rework Stations.

Oroville, California, USA

Consultant / Service Provider, Equipment Dealer / Broker / Auctions, Manufacturer's Representative, Training Provider

SMT Handling Equipment Automatic PCB Reject NG Buffer Conveyor For SMT Line

Description This equipment is used for AOI to separate the good board and the bad board. During the inspection, the good board can continue to run without hindrance Features 1.Reject,inspec...

SMT PCB Assembly Equipment Automatic smt pcb loader pcb handling equipment Nutek loader unloader

Factory price Automatic smt pcb Loader...

Dual Rails Reject Conveyor SMT PCB NG OK Conveyor With Top Quality For PCB Making Machine

Description This equipment is used for AOI to separate the good board and the bad board. During the inspection, the good board can continue to run without hindrance Features 1.Reject,inspec...

0.5m 0.8m 1.0m 1.2m 1.5m smt pcb inspection link transfer machine conveyor

0.5m 0.8m 1.0m 1.2m 1.5m smt pcb inspection link transfer machine conveyor...

Small pcb panel cutting machine v cut pcb depaneling machine For Aluminum SMD LED Board

Product introduction: 1.The nether linear blade is used to fix the PCB V-cut ,the upper circular blade moves to separ- ate t...

Iphone 6 motherboard reballing station Semi automatic bga rework station machine to desolder and solder chip on mobile pcb

Semi automatic bga rework station machine to desolder and solder chip on mobile pcb...

Solder Splatter Smelting Recycling Machine electroplate Tin Waste Slag Smelting Recovery Machine

HR-SD100 is an endeavor in reverting and recycling the oxides which occur during working of a Wave Soldering Machine in order to reduce production cost, create a greener environment and assist the quality process. Use special stirring syst...

Automatic PCBA Cleaning machine mobile ipa PCB Cleaner PCB Board liquid solvent spray alcohol SMTCleaning equipment

Automatic PCB Cleaning machine PCB Cleaner PCB Board Cleaning equipment ...

SMT Lead Free Wave Soldering Machine DIP Wave Soldering Pot Equipment for LED production line

PCB wave soldering machine HR-300E: 1. PLC and touchscreen controlling system which can save more than 50 sets parameters. User-frienly interface is easy to be operated,temperature can be set/saved/modified in touchscreen. 2....

Automated optical inspection manufacturers through hole 2d aoi inspection machine equipment smt systems software process

High precision smt aoi offline machine pcba offline aoi 2 conveyor aoi...

Pcb board separator led v cut manual pcb aluminium separator cutting depaneling machine

Pcb board separator v cut pcb aluminium separator features: 1.Decrease the stress , invoide the welding pot break. 2.Adjust the up guide slip by manual, which can solve the V cut...

PCB Handling Equipment SMT Inspection Conveyors 0.5m 1.0m conveyor electronic assembly conveyor

PCB Handling Equipment SMT Inspection Conveyors 0.5m 1.0m conveyor...

China Factory Direct Manufacture Full SMT 2 rails PCB Multi magazine unloader with CE for Assembly Production Line

Product introduction: 1.PLC control system,Working is stably and reliably; 2.Easy to operate LED touch screen control interface; 3.The pneumatic clamps of top and bottom three point provided for the magazin...

Stainless steel material PCBA surface conformal coating automatic removing machine

Automatic off line PCBA Cleaning machine China manufacturer Features: 1. A comprehensive cleaning system: the surface of the product residues of organic matter, inorganic substances for thorough and effe...

Economical and practical type off line selective wave soldering solder welding equipment machine

Economical and practical type offline selective welding equipment Features: 1.The machine integrates flux spraying,preheating and soldering. 2.The solder pot is fixed, and the PCB b...

Automatic Size Combination Multi Magazine PCB Board Loader Unloader With Ce Certificate For Wholesales

Product introduction: This unit is used to send PCBs out from magazine to SMT production line . Stable and reliable PLC control system; Easy to operate LED touch screen control interface; The pneumatic...

Flux Residual PCBA Cleaning Machine Chemical clean and DI water rinse machine

Features: 1. A comprehensive cleaning system: the surface of the product residues of organic matter, inorganic substances for thorough and effective cleaning; 2. Automatic cleaning mode: in a clean room to complete...

PCB Assembling Machine SMT LED SMD reflow soldering machine SMT reflow oven smt welding machine

High quality smt reflow soldering machine for sale Features: HR Series High End/Nitrogen Reflow Soldering Machine ¤Suitable For High End Products/Critical...

Shenzhen Honreal Technology Co.,Ltd

Shenzhen Honreal Technology Co., focus on global Surface Mount electronic assembly field for 15 years. Specializing in providing various brands of SMT pick and place machines and spare parts. Fuji, Panasonic, Juki, Hitachi, Yahama

Shenzhen, Guangdong, China

CoaXPress High Resolution Industrial Cameras

The CoaXPress series cameras operate 72fps with ZERO-ROT function at 8bit/10bit CXP-6 4CH It provides advanced technology of vision solution Sensor : 25MP Color & Mono CMOS Sensor (Global & Rolling Shutter)...

CameraLink High Resolution Industrial Cameras

The CameraLink industrial digital cameras offer high performance in a very small footprint. The advanced 25M color CMOS sensor provides the absolute best image quality at an incredible frame rate of 30 fps! The camera Link Interface ensures High s...

ISVI Razor High-Resolution Industrial Cameras, CMOS, 5120x5120, 4.5 pixel size

The RAZOR series cameras incorporate the most popular sensor resolutions with the ultimate in image performance, frame rates and economy. With scalable 1, 2 or 4 output links, RAZOR...

ISVI - Industrial Sensor Vision International Corporation

Industrial Sensor Vision International specializes in advanced camera technology of high resolution fast speed cameras for automation, AOI, 2-D/3-D, SPI inspection and wafer inspection.

Oxford, Connecticut, USA

used smt and semi machines buy and resell

used smt and THT , Semi machines buy and resell ...

HongCheng import & Export co.,Ltd

Buy and selling used smt,semi, Robot ,CNC and all used machines

Dongguan, Guangdong, China

ASYMTEK Products

Fluid Dispensing and Conformal Coating Solutions for Diverse Applications and Industries Nordson ASYMTEK supplies fluid dispensing and PCB conformal coating equipment that is supported by a global service network. Recognized for our...

MARCH PRODUCTS

Advanced Plasma Cleaning Systems, Solutions and Expertise for Multiple Manufacturing Industries MARCH Products is the global leader in advanced plasma surface treatment for semiconductor and electronic component manufacturi...

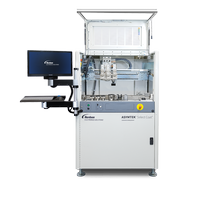

SELECT PRODUCTS

Selective Soldering Equipment and Solutions for Printed Circuit Board Assembly Nordson SELECT supplies selective soldering systems that are supported by a global service network. Recognized for our innovative products, we o...

Nordson Electronics Solutions makes reliable electronics an everyday reality. Our ASYMTEK, MARCH, and SELECT brands deliver precision fluid dispensing, conformal coating, plasma treatment and selective soldering equipment.

Carlsbad, California, USA

SMT Pick and Place Nozzles

High quality SMT nozzles, cutters, filters, etc. Featured Items: Siemens Nozzles Siemens Nozzle Type 911 Siemens Nozzle Type 914 Nozzle Ty...

SIEMENS/ASM SPARE PART

P/N Description 00047012-01 Cover cap CV-PK-4-B PUR...

Siemens Spare Parts

Siemens machine feeders and spare parts. Featured items: Siemens feeder module 12/16mm Siemens feeder module 24/32mm Siemens feeder mod. 44mm Siemens f...

SMT Consumables

Featured Items: Single 8mm tape Abrasive Block for Feeder Table Double side tape (8mm) SMT magazine rack Siemens Valve Plunger SP6 DST-8MM-00 (4)spli...

We offer various kinds of high quality SMT nozzles, feeders, cutters, filters, etc. Sales1@kundasmt.com

Suzhou, Jiangsu, China

Laser Cutting Services

Our Preco FlexPro CNC laser cutting system provides the speed of galvanometer processing with all the versatility of an XY motion system. Orion has the capability to cut detailed parts more precisely, and with shorter lead-times than conventional...

Waterjet Cutting

Waterjet allows for improved cutting tolerances, improved lead times and the ability to provide highly complex geometry. Using a stream of water with forces of 55,000 PSI yields fast production rates and tool free cutting. Our single hea...

Heavy Gauge Electrical Insulation

ORION has emerged as a leader in the fabrication of heavy gauge electrical insulation products. We route many materials such as TW Formex®, Statex®, GE's Lexan®, and acrylics. Their typical thicknesses is between 0.060" and 0.25&...

CNC Routed Plastics, Electronic Insulation Products

Through the process of CNC routing, we are able to cut with precision electronic insulation products including thicker gauge materials. We also process composite materials such as G-10, FR4 and other materials that are not easily...

Gaskets and Seals

Orion Industries Inc has over 35 years experience in the design and manufacture of high performance gaskets and seals. We fabricate parts from open cell sponge, closed cell sponge, and solid, dense gasketing materials. We also manufactur...

Thermal Transfer, Thermal Interface Materials

We are well versed in the following thermal application materials: Sil-Pad thermally conductive insulators Gap-Pad thermally conductive gap filling material ...

Formed Plastics Products

Formed parts are used for electrical insulation, such as snap-in-place housings, protection of high voltage parts, or covering bus bars. Plastics Forming Methods: Heated line bending...

Filters and Screens

Orion provides flexible, polyurethane filter foam to remove dust and contaminating particles from the air, gases and liquids in a variety of applications. The open pore skeletal structure provides low air resistance ideal for use in computers, ele...

Die Cutting, Stamping

Orion has high-speed die cutting presses ranging from 1 to 60 tons. We also have stamping presses that range from 1 to 60 tons. Our other Die cutting capabilities include: Production parts up to 60&qu...

EMI/RFI Shielding Laminates

To shield against emissions, there must be a barrier of an electrical conductive material. Shielding laminates provide an economical and effective solution to this problem. Most of our materials consist of a metal foil (usually, copper o...

ORION provides innovative solutions to our customers' EMI/RFI Shielding, Insulating, Screening and Sealing needs in a broad spectrum of manufacturing environments.

Ayer, Massachusetts, USA

Hydrotrue® RO 400 Series Water Treatment System

Hydrotrue® RO 400 series water treatment system Designed for DriSteem equipment and stand-alone operation, the Hydrotrue RO 400 Series reverse osmosis water treatment system significantly reduc...

XT Humidifier

XT Series electrode humidifiers provide humidification for a wide range of buildings, including health care, commercial, industrial, and government facilities. Easy installation and cylinder replacement together with minimal maintenance make XT Serie...

Adiatec® Ultrasonic Humidifier

The DriSteem Adiatec ultrasonic humidifier provides evaporative cooling and humidification in room or in AHU/duct for application flexibility. Ultrasonic units humidify using high frequency oscillation of piezoelectric transducers, causing mist to...

Hydrotrue® Pre-treatment Systems

Hydrotrue water softener systems The easiest and most cost-effective way to maintain humidification capacity and to reduce maintenance requirements is to install a Hydrotrue water softener system. Operating with...

Hydrotrue® RO 200 Series Water Treatment System

Hydrotrue® RO 200 series water treatment system Designed for DriSteem equipment and stand-alone operation, the Hydrotrue RO 200 series reverse osmosis water treatment system...

CDS dehumidifier RL series

DriSteem is introducing a brand-new selection of refrigerant-based dehumidifiers available to ship within 5 business days or less. These units are an excellent fit for commercial applications and replacement opportunities. Dehumidification...

GTS® Humidifier LX Series

The GTS humidifier LX Series is the only gas-fired humidifier that combines the highest efficiency on the market with ultra-low NOx in a single design. Thermal (combustion) efficiency 94% Higher Heating Value (...

DriSteem provides reliable and efficient humidity control, evaporative cooling, and water treatment solutions for commercial and industrial applications.

Eden Prairie, Minnesota, USA

Golden State Assembly - Wire Harnesses & Electromechanical Assemblies

Wire harnesses, electromechanical assemblies (box builds, subassemblies, PCBAs, kits, etc.), services (sorting, rework, value additive wire harness manufacturing engineering). Golden State Assembly is currently on the lookout...

Golden State is a contract manufacturer that makes wire harnesses, electromechanical assemblies (box builds, subassemblies, PCBAs, kits, etc.) and services (sorting, rework, value additive manufacturing engineering)

Morgan Hill, California, USA

Discrete Semiconductor Products

A semiconductor is a material that conducts electricity between a conductor and an insulator at normal atmospheric temperature. Common semiconductor materials contains silicon, germanium, gallium arsenide, etc. Silicon is the most influential in the...

Resistors

A resistor is a two-terminal electronic component made of resistive material with a certain structural form that can limit the flow of current in a circuit. The resistance value of a resistance element is generally dependent on temperature, material,...

Power Supplies - Board Mount

A power supply is a device that converts other forms of energy into electrical energy and supplies electrical energy to a circuit (electronic device). It provides the electrical energy needed by all the components in a computer. The size of power sup...

Integrated Circuits (ICs)

An integrated circuit is a circuit with specific functions that integrates a number of common electronic components, such as resistors, capacitors, transistors, etc., and the connections between these components through semiconductor technology. Thro...

Capacitors

Sandwiched between a layer of non-conductive insulation, two conductors close to each other, which constitutes a capacitor. A capacitor is a component that stores charge, and its storage is called capacity. Capacitors can be generally divided into fi...

Crystals and Oscillators

Some electronic devices require AC signals with high frequency stability, while LC oscillators have poor stability and are prone to frequency drift. In the oscillator using a special element - quartz crystal, can produce a highly stable signal, the u...

RF/IF and RFID

A reader, an electrical tag and data management system constitute an integrated RFID system. Radio Frequency Identification (RFID) is also regarded as a type of automatic identification technology. It carries out non-contact bidirectional data commun...

Filters

Filter is a filter circuit consisted of capacitance, inductance and resistance. The filter can effectively filter out the frequency points of a specific frequency or frequencies outside the frequency point in the power line, and obtain a power signal...

Memory Cards, Modules

In the integrated circuit, the circuit with storage function without physical form is also known as memory, such as RAM, FIFO, etc.; In the system, the storage device with physical form is also called memory, such as memory stick, TF card, etc. All t...

Isolators

Isolators are a kind of linear optical coupling isolation principle that output and convert the input signal. The input, output and working power supply are isolated from each other. Isolator, also known as signal isolator, is an significant part of...

Circuit Protection

Circuit protection is to protect electronic components in the circuit mainly in over voltage, over current, surge, electromagnetic interference. With the development of science and technology, electric/electronic products have been increasingly diver...

Sensors, Transducers

A sensor is a device that converts non-electrical quantities (such as temperature, humidity, light, magnetic field, sound, etc.) into electrical signals.Many types of sensors, mainly divided into physical sensors and chemical sensors. The physical...

Optoelectronics

Electronic displays refers to information display devices that use electronic technology to transform imperceptible signals into perceptible signals. Their characteristics include small-space occupancy, flexible display format, and simultaneously dis...

Relays

A relay is an electrical control device that can give a specified amount of input and hold it long enough to make a predetermined change in the controlled amount in the electrical output circuit. When the input drops to a certain level and remains fo...

Connectors, Interconnects

Connectors is a device that connects two active devices to transmit currents or signals. Domestic connectors, known as the connector and socket, generally refers to electrical connectors. Essential performances of connectors and interconnects can be...

Distributor of hot-sales and hard-to-find electronic and electromechanical components and supplies. Online catalogue, data sheets and purchasing. win-source.net

SPOKANE, Washington, USA

KSUN 330L Automatic Single Magazine Un loader

Model No: KSUN 330L Automatic Single Magazine Un loader PCB loading time: Approx 6seconds Magazine change-over time: Approx 30 seconds Power supply: 100-230V AC (customized ), single phase, MAX 300V/A...

RZS Automatic Radial Insertion Machine

RZS--Automatic Radial Insertion Machine Product name RZS Theoretica...

Refurbished YAMAHA YV100xg Pick and Place Machine

Refurbished YAMAHA YV100xg Pick and Place Machine Machine Type YV100XG Substrate size M type L460 * W335 (MAX)...

Panasonic NPM Modular SMT Chip Mounter Machine

Panasonic NPM Modular SMT Chip Mounter Machine Product name Panasonic NPM SMT Chip Mounter Model...

Refurbished Yamaha YV100 ll Pick and Place Machine

Refurbished Yamaha YV100 ll Pick and Place Machine Machine Type Automatic pick and place Brand Name Yamaha Machine Model...

KSUN 390 Automatic un Loader

Model No: KSUN 390 Automatic un Loader PCB loading time: Approx 6seconds Magazine change-over time: Approx 30 seconds Power supply: 100-230V AC (customized ), single phase, MAX 300V/A...

THK Grease AFE-CA From KINGSUN

THK Grease AFE-CA From KINGSUN More information about Products please Contact US at jenny@ksunsmt.com or visit www.ksunsmt.com...

KUSN 250L Automatic Single Magazine Un loader

Model No: KUSN 250L Automatic Single Magazine Un loader PCB loading time: Approx 6seconds Magazine change-over time: Approx 30 seconds Power supply: 100-230V AC (customized ), single phase, MAX 300V/A...

KSUN B350 Automatic vacuum loader

Model No: KSUN B350 Automatic vacuum loader MAX PCB`s capacity: 300pcs (0.6mm thickness PCB) cycling time: Approx 6 seconds Power supply: 100-230V AC (customized), single phase...

KSUN 460 Automatic PCB Inverter

product instruction ※ Stable and reliable integrated control system ※ Easy to operate touch screen control interface ※Using cylinder flip, quick, smooth, precise alignment ※Buffer deceleration design more...

KSUN 250 Automatic 90 degrees Turning Machine

product instruction ※ PLC control system, Working is stably and reliably ※ Enclosed design ensure the highest security level ※Balanced, stable, accurate rotation mode ※Easy to operate touch screen control...

YAMAHA YG200 Refurbished High Speed SMT Pick And Place Machine

YAMAHA YG200 is a high-speed SMD Surface Mounting machine, which has 4nos tables and totals 24 head nozzles, this machine mainly used for mount chip components, like 0201/0402/0603/0805/1206 or small QFN IC. “DONGGU...

KSUN 350 Automatic mobile conveyor

product instruction ※PLC control system, Working is stably and reliably ※Easy to operate touch screen control interface ※ Fast, stable and accurate stepper motor moves ※Enclosed design ensure the highest securi...

SAMSUNG SMT FEEDERS FROM KINGSUN

SAMSUNG SMT FEEDERS FROM KINGSUN SAMSUNG SM 8*2mm FEEDER SAMSUNG SM 8*4mm FEEDER SAMSUNG SM 12mm FEEDER SAMSUNG SM 16mm FEEDER SAMSUNG SM 24mm FEEDER SAMSUNG SM 32mm FEEDER SAMSUNG SM 44mm FEEDER S...

Refurbished Yamaha YV100X Pick and Place Machine

Refurbished Yamaha YV100X Pick and Place Machine MC Type YV100X PCB size L460 x W445 mm (Max.), L50 x W50 mm (Min.)or L460 x W335 mm...

KSUN 460 Automatic loader

Model No: KSUN 460 Automatic loader PCB loading time: Approx 6 seconds Magazine change-over time: Approx 30 seconds Power supply: 100-230V AC (customized ), single phase, MAX 300V/A Air pressure...

KSUN 330H Automatic Dual track un loader

Model No: KSUN 330H Automatic Dual track un loader PCB loading time: Approx 6seconds Magazine change-over time: Approx 30 seconds Power supply: 100-230V AC (customized ), single phase, MAX 300V/A...

JUKI RS-1R Next Generation Smart Fast Modular Mounter

JUKI RS-1R Next Generation Smart Fast Modular Mounter Model JUKI RS-1R Pick and Place Machine Conveyor Specification standar...

KS6V LED Placement Machine Domestic

KS6V LED Placement Machine Domestic Applicable to: fluorescent tubes,flexible light strips,flat lights,outdoor lights,ceiling lights, bulbs,terminals,power supplies,etc....

KSUN 390 NG/OK un loader

product instruction ※PLC control system, Working is stably and reliably ※Easy to operate touch screen control interface ※the pneumatic clamps of top and bottom three point provided for the magazin...

DONGGUAN KINGSUN AUTOMATION TECHNOLOGY CO.,LTD

DONGGUAN KINGSUN AUTOMATION TECHNOLOGY CO.,LTD is a company which mainly provide used and new SMT parts, provide repair SMT key parts service,new/used SMT machine trading,SMT consumables and Peripherals equipment,Clean room, ESD..

Dongguan, China

Consultant / Service Provider, Distributor, Equipment Dealer / Broker / Auctions, Manufacturer, Manufacturer's Representative

Yamaha YV100II Pick and Place Machine

http://www.flason-smt.com/product/Yamaha-YV100II-Pick-and-Place-Machine.html Yamaha YV100II Pick and Place Machine Yamaha YV100II Pick an...

Hitachi nozzle HG33C for GXH-3/Sigma G4/G5 machine

http://www.flason-smt.com/product/Hitachi-nozzle-HG33C-for-GXH-3-Sigma-G4-G5-machine.html Hitachi nozzle HG33C for GXH-3/Sigma G4/G5 machine &#x...

LED Manufacturing Machine

http://www.flason-smt.com/product/LED-Manufacturing-Machine.html LED Manufacturing Machine Applicable Components: 0603?20mm...

Flason SMT PCB Manufacturing Equipment

Flason SMT PCB Manufacturing Equipment Name: SMT Reflow Oven Heating zones: 12 He...

IR Lead Free SMT Reflow Oven A8

IR Lead Free SMT Reflow Oven A8 IR Lead Free SMT Reflow Oven Lead Free SMT Reflow Oven IR SMT Reflow Oven...

ASSEMBLEON YAMAHA TYPE 211F Nozzle

http://www.flason-smt.com/product/ASSEMBLEON-YAMAHA-TYPE-211F-Nozzle.html ASSEMBLEON YAMAHA TYPE 211F Nozzle...

Flason SMT OEM SMT Assembly line wave soldering machine Factory

Flason SMT OEM SMT Assembly line wave soldering machine Factory Weight: 700KG Dimensions: 2100(L)*1200...

Samsung SM321 SM411 SM421 SM471 feeder

http://www.flason-smt.com/product/Samsung-SM321-SM411-SM421-SM471-feeder.html Samsung SM321 SM411 SM421 SM471 feeder &#...

Panasonic CM202-DS CM201-DS Pick and Place Machine

http://www.flason-smt.com/product/Panasonic-CM202-DS-CM201-DS-Pick-and-Place-Machine.html Panasonic CM202-DS CM201-DS Pick and Place Machine &#x...

LED Assembly Line Reflow Soldering Oven M8

LED Assembly Line Reflow Soldering Oven M8 LED Assembly Line Reflow Soldering Oven LED Reflow Soldering Oven LED Line Reflow Soldering Oven...

PANASONIC MPA G3 Nozzle

http://www.flason-smt.com/product/PANASONIC-MPA-G3-Nozzle.html PANASONIC MPA G3 Nozzle SMT Nozzle...

4 Heating Zones Small Reflow Oven

4 Heating Zones Small Reflow Oven Max width of PCB board 300mm Heating zones: 6 Heating method: Hot Air...

PCB circuit Verify Repair Machine VRS

PCB circuit Verify Repair Machine VRS Identification of defects:red laser instructions Maintenance Area:24″×...

SMT Reflow Oven M6

SMT Reflow Oven M6 Max. Width of PCB 350mm Heating zones: 6 Heating method: Hot Air &#x...

China SMT wave soldering machine factory Supplier Manufacturer

Wave Soldering Machine...

JUKI SMT 500 Nozzle 40011046

http://www.flason-smt.com/product/JUKI-SMT-500-Nozzle-40011046.html JUKI SMT 500 Nozzle 40011046 SMT Noz...

Panasonic Emboss Feeder Emboss 10488BB082 8Wx4P

Panasonic Emboss Feeder Emboss 10488BB082 8Wx4P Panasonic Emboss Feeder Emboss 10488BB082 8Wx4P SMT Spare Parts Panasonic feeder &#x...

High Speed SMT Assembly line

High Speed SMT Assembly line High Speed SMT Production line High Speed PCB Assembly line High Speed PCB Production line...

Siemens Stick Feeder