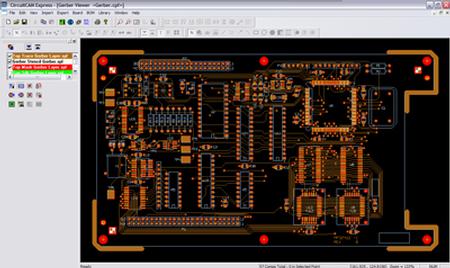

JUKI's IS software package provides managers, supervisors and engineers with the tools required to run the most efficient production possible, and has been seamlessly integrated with AEGIS’ CircuitCAM Express, now branded as NPI Plus. This seamless integration provides a full set of CAD importers and Gerber processing with direct library management access to IS for graphical part matching and machine angle verification. Additionally, a feeder setup report for viewing the part as loaded in the feeder.

"The integration of CircuitCam Express NPI Plus into our IS software gives us the ability to provide a complete software and hardware solution for our customers from the prototype process to high- volume production. This is of great benefit to our customers and is a reflection of the strong relationship that Juki has with Aegis." said Juki Marketing Manager, Geron Ryden.

"This unique programmatic bridge between the two software platforms delivers the overall experience and capability customers want. Their usage experience appears as a singular software system, while, in fact, they are leveraging the core competencies of both JUKI and Aegis. The result is ease of use, rapid data preparation, and all the line optimization and management benefits only the machine manufacturer can effectively provide," adds AEGIS CEO, Jason Spera.

Juki Corporation's (http://www.jas-smt.com) experience as the market leader in industrial sewing machines was the stepping-stone for the entry into the printed circuit board assembly market in 1987. Since then, Juki has delivered more than 24,000 automated assembly systems worldwide and is currently shipping an average of 200 assembly machines per month. This extraordinary achievement makes Juki one of the world’s leading providers of automated assembly products and systems. In addition to its core technologies, Juki’s Electronic Assembly and Test Systems Division develops and manufactures advanced electronic systems and computer software for data entry, mail processing and other electronic equipment.

Aegis systems (http://www.aiscorp.com) provide hi-tech manufacturers improved speed, control, and visibility of all aspects of factory operations so they can do more with less. Today, manufacturers must maintain fewer assets, but achieve more utilization. They require less cost, but faster product launches and reporting, as well as less overhead, but total traceability. The Aegis Manufacturing Operations System (MOS) supports these goals, and delivers them in a way that defines and contains the investment required to complete the full system deployment.