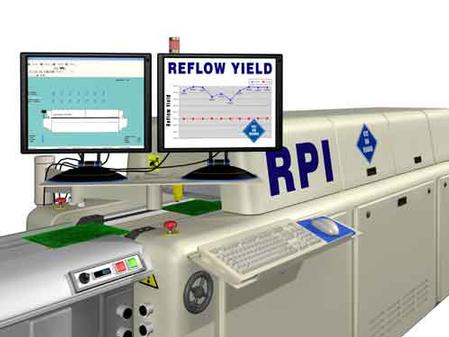

On display will be the RPI - Reflow Process Inspection, which is an in-line process inspection system for SMT reflow ovens. The system is embedded inside the reflow oven and checks the profile for each and every product processed through the oven to verify whether the profile is in spec. On a daily basis, the system will generate two charts: DPMO (Defects Per Million Opportunities) and Process Yield for the thermal process.

The industry, to a large degree, now relies on AOI systems to inspect their assemblies. The AOI system is not designed to look at joints hidden under the components body as in the case of BGA, PoP and other such components. Some companies use X-ray inspection on these components. The in-line systems tend to be extremely expensive while the more popular off-line systems suffer from the slow speed and batch mode used in today's highly automated in-line SMT factory. More importantly, however, neither of these systems detects defects associated with solder joints that have been processed out of spec. Examples include inadequate wetting, too large or too small grain structure, and even certain types of opens and cold soldered joints.

The RPI inspects the core of the issue that determines the joint quality or defects: Were the products processed within the relevant thermal process parameters? Finally, rather than overwhelming the manager or engineer with data, the RPI generates only two datapoints (DPMO and Yield) in a simple chart to tell if the thermal process is healthy or not.

While the standard KIC Explorer introduced plug-and-play profiling for quick and accurate temperature-time measurements, the RF version provides several additional benefits. The unproductive dead time typically associated with waiting for the profiler to exit is replaced by real-time process data that instantly show what is going on with the process. In addition to a more convenient and faster operation, there is less danger to the profiler or production board because any over-temperature situation is instantly revealed and corrective action can be taken.

The KIC Explorer RF also alerts the operator of the many possible pitfalls that can make profiling an unproductive task, including the following:

- Forgetting to turn the profiler on prior to a run

- A TC pops off

- Wrong oven recipe

- The profiler gets stuck in the oven tunnel

Based in San Diego, KIC is the industry leader in automated thermal management tools and systems for reflow, wave, cure and semiconductor thermal processes. The company pioneered the development of oven profilers and process development tools, and then worked to create the next generation of thermal systems to help manufacturers optimize and monitor thermal processes.

In addition to KIC Explorer, products include the KIC�24/7 continuous monitoring system, the KIC Vision automatic profiling system and more. With the introduction of cutting edge tools, the company continues to stay on the leading edge of process optimization and real-time thermal management systems, and has won numerous industry awards.