Today, cleaning of PCB and other spare parts is almost mandatory in SMT production plants, especially in high-end areas. PCB must be thoroughly cleaned of production residues as well as dirt to ensure reliable further processing and trouble-free performance. Other spare parts will also degrade over time with the equipment. For example, the nozzle of the pick and place machine will be used for a long time, and the nozzle hole will be blocked by dust, which needs to be cleaned regularly.

In the SMT industry, there are many types of cleaning machines. According to the cleaning things, there are stencil cleaner, PCBA cleaner, Wave Oven Pallet/Fixture cleaner, Mis-Print PCB cleaner, Squeegee cleaner, Nozzle cleaner, PCB surface cleaner and so on.

Especially where sensitive and thus mostly expensive modules are used, such as in the aerospace industry, the automotive industry, in medical technology or telecommunications, the assembled PCB board cleaning is a full and important production step.

But even with the so-called no-clean manufacturing, it may be that these components must be cleaned to avoid malfunctions. The thorough removal of flux residues, colophony, resin, oxides and soldering materials are the main tasks in the cleaning of printed circuit boards, active and passive electronic components, BGA, flip chip, relays, inductors, etc.

Why Clean PCBA?

Improve the aesthetics of the PCBA

If you are a contract manufacturer of PCBA, the visual appearance of the board reflects the quality of your product. Clear greasy residue and flux burnt to form spots that customers can easily perceive as a defective product.

Improve PCB reliability

Reliability requirements are usually determined by the nature of the final product. For example, there will be very strict requirements for pacemaker electronics where a circuit board failure could directly lead to death.

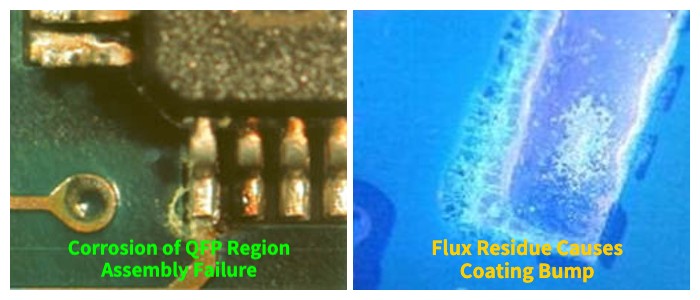

Prevent component and PCB corrosion

Flux residues left on electronic circuit boards are acidic. If they are not removed through a cleaning process, the residue can absorb ambient moisture from the air and cause corrosion of component leads and PCB contacts.

Avoids Adhesion Issues with Conformal Coatings

Most people understand that when painting, the surface must be prepared so that it is absolutely clean. Otherwise the paint will peel off quickly. Conformal coating logic is the same as painting.

To make matters worse, the coating is often semi-permeable, and moisture can get in and seep into the flux residue and cause corrosion.

Prevents ionic contamination

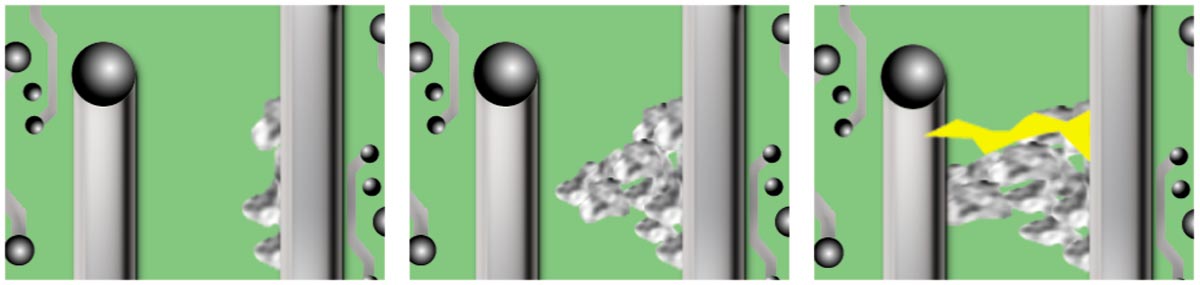

Polar or ionic particles left over from flux residues and other sources, when exposed to moisture in ambient air and an electrical current are applied, can connect into chains or branches called dendrites . These dendrites are electrically conductive, so they can form unintended traces that can lead to current leakage, or even short circuits for extended periods of time.

SMT PCBA Cleaning Machine I.C.T-5600

I.C.T-5600 is an integrated high-end cleaning machine that is energy-saving, environmentally friendly, and batch cleaning. It can automatically complete the functions of cleaning, rinsing, and drying.

Mainly used for the cleaning of multi-variety, medium and small batch PCBA boards of high-end products in the automotive electronics, military, medical, aerospace, communications, smart instrumentation and other industries.

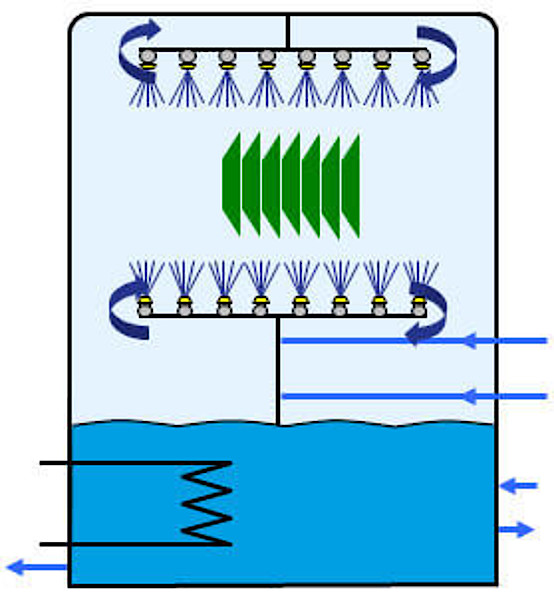

I.C.T-5600 can automatically complete the whole process of cleaning, rinsing and drying with one key through the spray system that can adjust the pressure. The cleaning room contains two layers of cleaning baskets, which can clean more boards at one time. Thoroughly and effectively clean organic and inorganic pollutants such as rosin, no-clean flux, water-soluble flux and other organic and inorganic pollutants on the surface of SMT/THT PCBA after soldering. The circulating filtration system of the cleaning solution can use the cleaning solution more times and reduce the waste of the cleaning solution.

How to ensure no blind spot cleaning?

In I.C.T-5600 single chamber spray systems, cleaning occurs according to the dishwasher principle. All of the process steps are executed in the same process chamber. The cleaning medium is sprayed onto the electronic assemblies through nozzle fittings or rotating spray arms. The cleaning effect is generally not achieved through spray jet pressure, as with inline processes, but rather via the volume of cleaning medium passed over the substrates.

The nozzles on the rotating spray bar are specially designed. The size and distribution density of the nozzles are different. After our countless tests, the left and right incremental distribution and the up and down dislocation distribution are adopted, which not only improves the cleaning efficiency, but also completely solves the problem of clean blind spots. And the rotating spray rod adopts a lubrication-free design, which runs smoothly and does not need to be replaced regularly.

Will high pressure cleaning damage components?

Some engineers will be concerned about whether their PCBA size is too small, will it be damaged by high pressure washing, or will it be damaged due to collision between PCBA?

The pressure of each spray rod can be adjusted manually by computer, and different pressure values can be set according to different sizes of PCBA. After repeated tests, it can solve the problem of collision and displacement under high pressure spray conditions. The injection pressure can be adjusted from 30 to 80 PSI.

Does it consume a lot of cleaning agent?

The built-in filtration system and concentration compensation system are adopted to effectively save the consumption of cleaning solution.

The cleaning machine will initially use a proportional pump to mix the cleaning liquid and DI water in proportion, and the used cleaning liquid will enter the filtration system to filter out all solid residues above 0.2um. As the number of times of use increases, the concentration compensation system of the cleaning machine will automatically replenish the cleaning solution according to the decrease in concentration, so as to achieve the standard ratio.

How to prevent ionic contamination?

DI-250 is a deionized water generator used together with I.C.T-5600. The cleaning solution will add DI water in proportion, and the rinsing process is full of deionized water for rinsing.

ICT-5600 will be equipped with a conductivity tester as standard. When the machine automatically enters the rinsing process, it can monitor the state of the rinsing water at any time until the PCBA board reaches the preset cleanliness. This function greatly improves the continuity of the cleaning process.

How about the on-line PCBA cleaning machine?

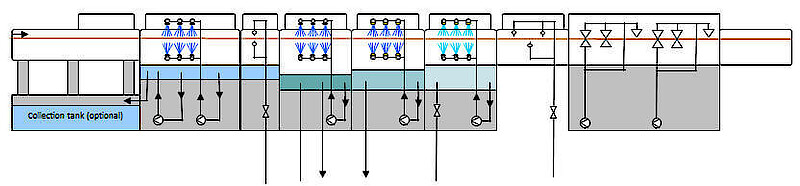

For high production volumes and minimal component variety, on-line cleaners I.C.T-6300 are a time-saving and cost-effective solution when cleaning electronic components. The printed circuit boards run automatically on a conveyor belt through the individual process steps, where cleaning, rinsing and drying take place in separate chambers.

For high production volumes and minimal component variety, on-line cleaners I.C.T-6300 are a time-saving and cost-effective solution when cleaning electronic components. The printed circuit boards run automatically on a conveyor belt through the individual process steps, where cleaning, rinsing and drying take place in separate chambers.

Before deciding on the onlining process, it is necessary to consider the venue. Compared to the off-line I.C.T-5600, an on-line washer requires a larger footprint. Inline systems can only be integrated into the production line if the entry and exit of components and the cleaning itself are fully automated.

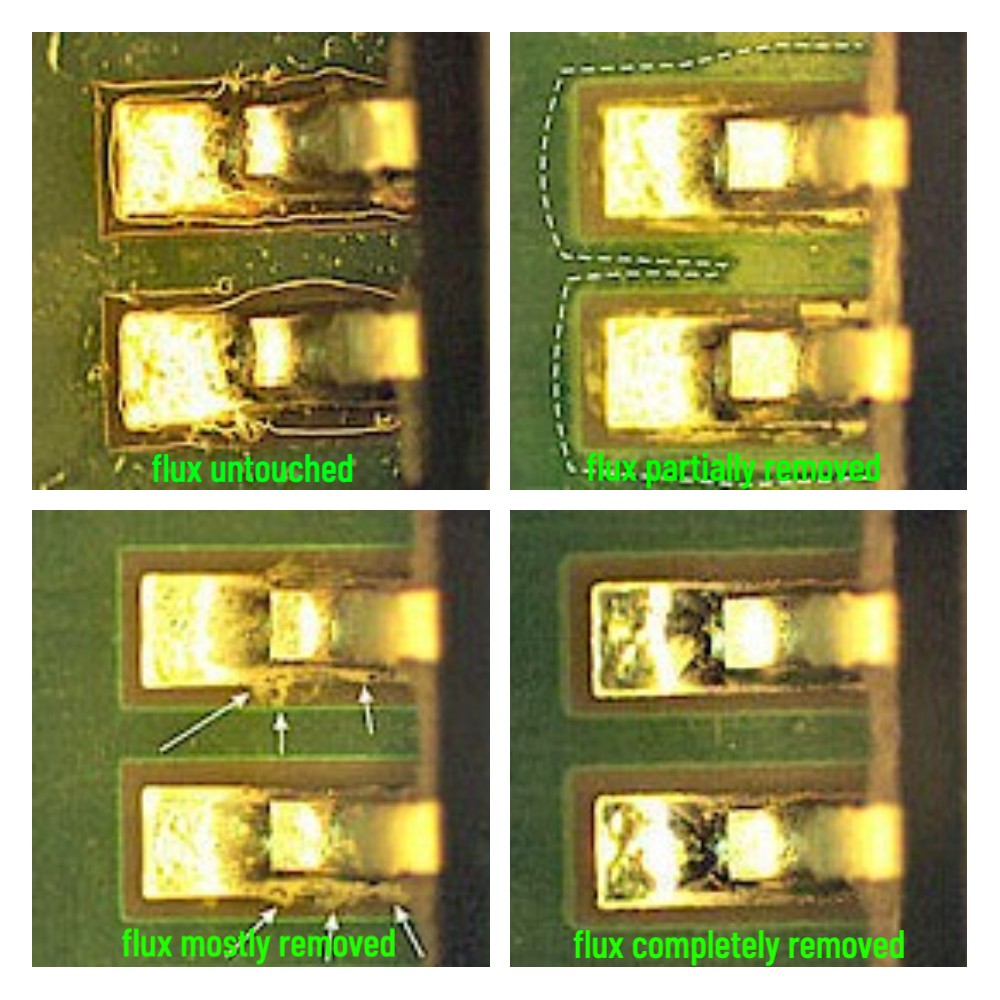

Comparison chart of cleaning effect

If you have questions about the different cleaning mechanisms/process types, please contact our process engineers: info@smt11.com

»

»