Continuous Volumetric Two-Component (2K) Mixer for Dispensing

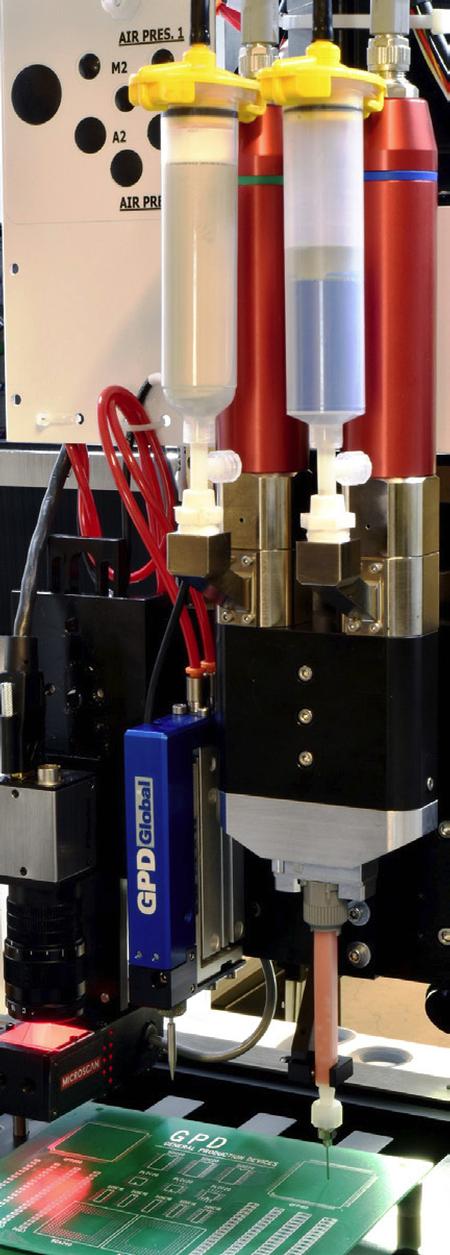

GPD Global, a manufacturer of precision fluid dispensing systems for high-volume 24/7, low-volume/high-mix, and R&D production, offers uniquely designed 2-part mixing pump to accurately mix and dispense two-part components while eliminating entrapped air.

Functions and Features - Volumetric 2-part mixing pump

The continuous volumetric 2-part mixing pump (2K or Bi Component or Two-Component Mixing) is based on volumetric Progressive Cavity Displacement (PCD) technology. This volumetric two-component mixer moves parts A+B fluid through a static mixer at an adjustable mix ratio. The two-components are uniformly mixed in the disposable static mixer - the only part wetted by both fluids. Static mixers are available in different sizes, lengths, and number of mixing elements - depending on the mixing requirements of the fluid. Unlike piston based mixing systems, recharge is not required.

The volumetric drive system is available in highly polished alloy or ceramic for abrasive fluids. The pumps are driven electrically for dispense rates up to 4.5 cc/min depending on configuration. The mix ratio is adjustable by controlling the speed of the individual pumps. This allows for a customized ratio; for example, a ratio of 1.2:1. Large ratios, up to 20:1, are also attainable.

Applications of the Volumetric 2-part mixing pump

The Volumetric 2-part mixing pump with its PCD technology enhances applications requiring two-component mixing by handling a wide range of fluids and being able to adjust the mix ratios to suit your needs. Below are some applications and materials that may be used with the pumps for metering or transferring:

- Adhesives and sealants with or without spherical fillers

- Encapsulant and potting fluids

- Gasketing, dot, or bead applications

- Suitable for two-component adhesive systems based on: epoxy resin (EP), polyurethane (PU), silicone (Si), methyl methacrylate (MMA), urethanes, UVs, sealants, etc.

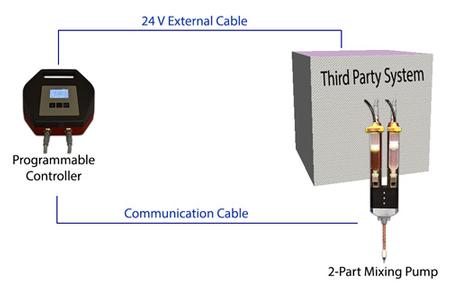

Integration of the Volumetric 2-part mixing pump

PCD 2-Part mixing pump can be easily integrated into tabletop robots or fully automated platforms. The programmable controller allows you to calibrate the dispensing volume from each pump for accurate mix ratios. Interfacing to the controller requires a simple 24 V signal to initiate dispensing. More details about 2-Part Mixing Pump Integration.

Programmable Controller

The controller allows you to program the mix ratio of the pump and make final adjustments to the mix ratio, as well as calibrate the pump for appropriate volumetric dispensing. Time, volume, and on/off modes can be set to suit your dispensing needs. Up to 10 programs can be saved to the controller for selection.

Integration is simple - the controller easily interfaces with any robot via a 24 V external signal.

A reverse or suck back operation can be programmed to prevent dripping.

Refer to 2-Part Mixing Pump data sheet for more details about Programmable Controller.

GPD Global is an equipment manufacturer of high-quality, precision, automated fluid dispensing and component-prep systems. The company is an international, state-of-the-art equipment supplier for the PCB assembly and semiconductor industries. It designs and manufactures a variety of automatic fluid dispense systems, as well as manufactures an SMT Cover Tape Peel Tester and Component Prep equipment for Thru-Hole applications. GPD Global is committed to offering premium service to its customers and has sales and customer support affiliates located throughout the world, including North America, South America, Europe, the Middle East and Asia-Pacific.

»

»