With “Securo”, Rehm Thermal Systems offers a new series for reliable hot and cold function tests

Electronic components in safety-relevant applications such as medical, automotive and aerospace technology must function 100 % reliably under all temperature conditions. To analyse the reliability of electronics under extreme temperatures, Rehm Thermal Systems has developed a completely new series: Securo Plus for hot function tests and Securo Minus for cold function tests. The systems can simulate precisely these extreme environmental conditions by selectively heating or cooling the component.

Inspection and measurement procedures under extreme temperatures are increasingly becoming standard, particularly in the car manufacturing sector, in order to test and analyse the function of components under real environmental conditions. Any failure or series error can result in high costs and have far-reaching consequences.

To check the winter suitability of sensitive electronics, in the Securo Minus system the components can be exposed to air or nitrogen flows at temperatures as low as -55 °C and subsequently tested. On the other hand, to simulate the installation environment in the vehicle interior, for example, in the Securo Plus system the components are heated up to between +80 °C and +120 °C. The new series offers complete flexibility and safety in the design and implementation of test tasks. A stable rotating goods carrier transport ensures safe transport of the components through the system and absolute process stability. The systems have a variety of loading and unloading options and sufficient intake capacity to reliably get even large parts to the desired test temperature with short cycle times.

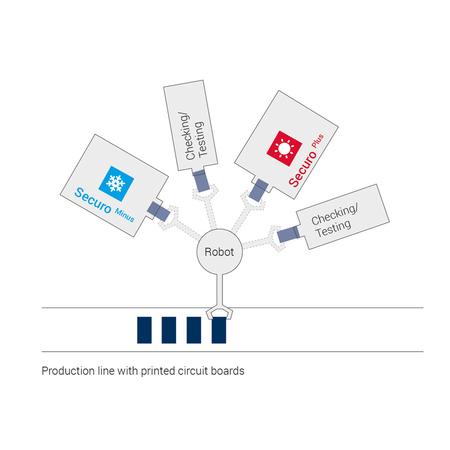

The new hot and cold function test systems from Rehm are also modular and can be configured as inline or isolated solutions. In the inline variant, the selective heating or cooling and subsequent functional testing are firmly linked. This solution is economical for large quantities and low cycle times. In the isolated variant, the heating or cooling and subsequent functional testing are highly flexible and depend on variant, quantity and cycle time. The systems operate reliably with dried air or in a nitrogen atmosphere.