News Releases from SZTech-SMT Firm

Read SZTech-SMT Firm company news

- SMTnet

- »

- News

- »

- News Contributors

- »

- News Releases from SZTech-SMT Firm

25 news releases added by SZTech-SMT Firm

Company Information:

How to maintain SMT machine?

![]() Jul 10, 2023 | SMT machine maintenance

How to maintain an SMT machine?

Abstract: The placement machine is the core and most important equipment in the entire SMT placement process. Whether the placement machine works normally directly affects the efficiency and quality of the entire production line. Therefore, the equipment should be by the daily, Weekly, and monthly maintenance records used for maintenance to ensure the stability of the placement machine and the accuracy of placement processing. At the same time, we must pay attention to safety matters in the daily use of equipment to ensure the normal operation of the machine and protect personal safety. The following sztech-smt will introduce to you the maintenance and precautions required for the SMT placement machine during use and operation.

Jul 10, 2023 | SMT machine maintenance

How to maintain an SMT machine?

Abstract: The placement machine is the core and most important equipment in the entire SMT placement process. Whether the placement machine works normally directly affects the efficiency and quality of the entire production line. Therefore, the equipment should be by the daily, Weekly, and monthly maintenance records used for maintenance to ensure the stability of the placement machine and the accuracy of placement processing. At the same time, we must pay attention to safety matters in the daily use of equipment to ensure the normal operation of the machine and protect personal safety. The following sztech-smt will introduce to you the maintenance and precautions required for the SMT placement machine during use and operation.

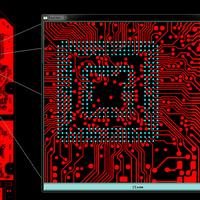

How to inspect BGA solder joints in SMT processing?

![]() Jul 10, 2023 | BGA inspection: how to inspect BGA solder joints in SMT processing?

Abstract: In the process of SMT patch processing, we often encounter BGA devices, which are also the core components of the entire PCBA. If a fully functioning PCBA is compared to a person, then the core of the command center or brain must be a BGA device. The quality of BGA soldering is directly related to whether the entire PCBA board can work normally, whether the BGA soldering can be accurately controlled during SMT patch processing, and whether the subsequent inspection can detect whether there are hidden dangers in the soldering problem, and can solve it. Take appropriate action.

Jul 10, 2023 | BGA inspection: how to inspect BGA solder joints in SMT processing?

Abstract: In the process of SMT patch processing, we often encounter BGA devices, which are also the core components of the entire PCBA. If a fully functioning PCBA is compared to a person, then the core of the command center or brain must be a BGA device. The quality of BGA soldering is directly related to whether the entire PCBA board can work normally, whether the BGA soldering can be accurately controlled during SMT patch processing, and whether the subsequent inspection can detect whether there are hidden dangers in the soldering problem, and can solve it. Take appropriate action.

What is the principle of AOI inspection?

![]() Jul 10, 2023 | Abstract: AOI is a kind of inspection equipment in SMT processing, also known as AOI optical automatic inspection equipment, which has become an important inspection tool and process quality control tool for the electronic manufacturing industry to ensure product quality. The working principle of AOI testing equipment is that during the automatic testing process, the AOI testing equipment machine automatically scans the PCBA product through the high-definition CCD camera, collects images, compares the test points with the qualified parameters in the database, and checks out the solder on the target PCBA after image processing. Point defects, and mark defects by display or automatically. Improve process parameters for maintenance personnel maintenance and SMT craftsmen.

Jul 10, 2023 | Abstract: AOI is a kind of inspection equipment in SMT processing, also known as AOI optical automatic inspection equipment, which has become an important inspection tool and process quality control tool for the electronic manufacturing industry to ensure product quality. The working principle of AOI testing equipment is that during the automatic testing process, the AOI testing equipment machine automatically scans the PCBA product through the high-definition CCD camera, collects images, compares the test points with the qualified parameters in the database, and checks out the solder on the target PCBA after image processing. Point defects, and mark defects by display or automatically. Improve process parameters for maintenance personnel maintenance and SMT craftsmen.

What is the precaution for the SMT production process?

![]() Jul 10, 2023 | Precaution for the SMT

Preparation before production

1. Non-vacuum packaged PCB, QFP, BGA, IC (customer requires baking) and other components must be baked before going online. Implementation of "SMT Parts Baking Operation Instructions".

2. The warehouse formulates the "SMT Chip Issue List" based on the "BOM List".

3. SMT patch receives materials according to the relevant model "SMT patch material delivery list", and confirms the material model, specification, quantity, and other conditions, the warehouse is responsible for follow-up and replenishment of missing materials, or the customer requires a blank sticker to issue an "empty patch" Sticker".

4. According to the SMT chip production plan, the project confirms the BOM, process requirements, SMT chip program, fixtures, tools, and other pre-production preparations.

5. The process department and the quality department should provide the corresponding inspection specification documents.

6. SMT elongation should arrange personnel and materials according to relevant documents such as "BOM list", "Process Requirements", and "SMT patch station table" corresponding to the corresponding model.

Jul 10, 2023 | Precaution for the SMT

Preparation before production

1. Non-vacuum packaged PCB, QFP, BGA, IC (customer requires baking) and other components must be baked before going online. Implementation of "SMT Parts Baking Operation Instructions".

2. The warehouse formulates the "SMT Chip Issue List" based on the "BOM List".

3. SMT patch receives materials according to the relevant model "SMT patch material delivery list", and confirms the material model, specification, quantity, and other conditions, the warehouse is responsible for follow-up and replenishment of missing materials, or the customer requires a blank sticker to issue an "empty patch" Sticker".

4. According to the SMT chip production plan, the project confirms the BOM, process requirements, SMT chip program, fixtures, tools, and other pre-production preparations.

5. The process department and the quality department should provide the corresponding inspection specification documents.

6. SMT elongation should arrange personnel and materials according to relevant documents such as "BOM list", "Process Requirements", and "SMT patch station table" corresponding to the corresponding model.

Precautions for SMT production line

![]() Jun 01, 2023 | Precautions for SMT production line

Jun 01, 2023 | Precautions for SMT production line

What is the SMT process flow? Check SMT process introduction

![]() May 20, 2023 | SMT Process Flow

SMT process flow refers to surface mount technology, which is the processing and welding of components on the basis of a printed circuit board PCB, referred to as SMT. It is currently the most popular process for electronic product processing and welding. The basic process of SMT includes solder paste printing, electronic component placement, reflow soldering, AOI optical solder joint inspection, X-ray perspective inspection, maintenance, cleaning, etc. Now electronic products are increasingly pursuing miniaturization. The plug-in method can no longer satisfy the status quo, and only surface mount technology SMT can be used. Today SZTech-SMT will introduce, what are the SMT patch processing processes.

Abstract: First, the basic process components of SMT patch processing are: solder paste printing (red glue printing), SPI, patch, first article inspection, reflow soldering, AOI inspection, X-ray, rework, and cleaning. The following explains the role of each process one by one.

May 20, 2023 | SMT Process Flow

SMT process flow refers to surface mount technology, which is the processing and welding of components on the basis of a printed circuit board PCB, referred to as SMT. It is currently the most popular process for electronic product processing and welding. The basic process of SMT includes solder paste printing, electronic component placement, reflow soldering, AOI optical solder joint inspection, X-ray perspective inspection, maintenance, cleaning, etc. Now electronic products are increasingly pursuing miniaturization. The plug-in method can no longer satisfy the status quo, and only surface mount technology SMT can be used. Today SZTech-SMT will introduce, what are the SMT patch processing processes.

Abstract: First, the basic process components of SMT patch processing are: solder paste printing (red glue printing), SPI, patch, first article inspection, reflow soldering, AOI inspection, X-ray, rework, and cleaning. The following explains the role of each process one by one.

How does SMT solder paste affect soldering quality?

![]() May 20, 2023 | Solder paste affects soldering quality

How does SMT solder paste affect soldering quality?

Abstract: Solder paste is composed of solder alloy powder and flux, and flux is composed of solvent, film-forming substance, activator, and thixotropic agent. Solder paste is a very important part of the SMT placement process. The size of the metal powder in the solder paste, the ratio of metal content, the ratio of flux components, the time of warming up before use, the stirring time, and the storage environment and storage time of the solder paste will all affect the soldering quality. The following SZTech-SMT will briefly talk about the components of SMT solder paste and what are the effects on soldering quality.

May 20, 2023 | Solder paste affects soldering quality

How does SMT solder paste affect soldering quality?

Abstract: Solder paste is composed of solder alloy powder and flux, and flux is composed of solvent, film-forming substance, activator, and thixotropic agent. Solder paste is a very important part of the SMT placement process. The size of the metal powder in the solder paste, the ratio of metal content, the ratio of flux components, the time of warming up before use, the stirring time, and the storage environment and storage time of the solder paste will all affect the soldering quality. The following SZTech-SMT will briefly talk about the components of SMT solder paste and what are the effects on soldering quality.

What is the core machine of the SMT processing plant?

![]() May 20, 2023 | Core machine of the SMT

Abstract: In the SMT chip processing factory, there are many pieces of production equipment in the SMT workshop, so among the many devices, what equipment is the core equipment in SMT chip processing? Today, SZTech-SMT will explain to you what is the core equipment of the SMT patch processing plant.

May 20, 2023 | Core machine of the SMT

Abstract: In the SMT chip processing factory, there are many pieces of production equipment in the SMT workshop, so among the many devices, what equipment is the core equipment in SMT chip processing? Today, SZTech-SMT will explain to you what is the core equipment of the SMT patch processing plant.

How to effectively store and use solder paste in an SMT patch processing factory?

![]() May 20, 2023 | Store and use solder paste

Abstract: Solder paste in SMT processing is a solder paste with a certain viscosity and good thixotropy by mixing powdered solder powder alloy, flux, and some additives that play a role in viscosity and other functions. In the process of SMT patch processing and welding, solder paste is a key factor in quality control, so how should we better control and use solder paste? The following SZTech-SMT will give you a brief explanation.

May 20, 2023 | Store and use solder paste

Abstract: Solder paste in SMT processing is a solder paste with a certain viscosity and good thixotropy by mixing powdered solder powder alloy, flux, and some additives that play a role in viscosity and other functions. In the process of SMT patch processing and welding, solder paste is a key factor in quality control, so how should we better control and use solder paste? The following SZTech-SMT will give you a brief explanation.

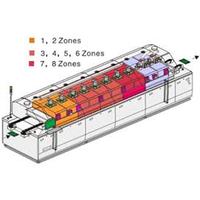

What is the working principle of SMT reflow soldering?

![]() May 20, 2023 | Working principle of SMT reflow soldering oven

Abstract: Due to the development and progress of science and technology, the electronic products we are exposed to are constantly miniaturized. In the PCBA welding process, more chip components are welded. The traditional welding method can no longer meet the current industry development needs. Therefore, the reflow soldering method is adopted in the SMT chip processing process. Most of the components processed by the SMT chip are chip type, mounted transistors, ICs, etc. With the technological development of the entire SMT industry becoming more and more perfect and common, a variety of patch-processing components have emerged. As a part of SMT processing technology, the reflow soldering process technology and equipment have also been developed accordingly, and its application is becoming more and more extensive. Now it has been widely used in all electronic product fields.

May 20, 2023 | Working principle of SMT reflow soldering oven

Abstract: Due to the development and progress of science and technology, the electronic products we are exposed to are constantly miniaturized. In the PCBA welding process, more chip components are welded. The traditional welding method can no longer meet the current industry development needs. Therefore, the reflow soldering method is adopted in the SMT chip processing process. Most of the components processed by the SMT chip are chip type, mounted transistors, ICs, etc. With the technological development of the entire SMT industry becoming more and more perfect and common, a variety of patch-processing components have emerged. As a part of SMT processing technology, the reflow soldering process technology and equipment have also been developed accordingly, and its application is becoming more and more extensive. Now it has been widely used in all electronic product fields.

What is the reflow soldering process requirement for PCBA processing?

![]() May 20, 2023 | Reflow soldering process requirement of SMT

Abstract: Reflow soldering is an important part of the SMT placement process. It is an important link to form the connection between components and circuit board electrical appliances after front-end PCB solder paste printing and PCB patch installation. Reflow soldering is to melt the solder paste into liquid by internal heating to weld components and PCB pads together. The components and pads are then solidified together by cooling. So what are the important process requirements for reflow soldering? The following SZTech-SMT will give you a detailed introduction to the reflow soldering process requirements.

May 20, 2023 | Reflow soldering process requirement of SMT

Abstract: Reflow soldering is an important part of the SMT placement process. It is an important link to form the connection between components and circuit board electrical appliances after front-end PCB solder paste printing and PCB patch installation. Reflow soldering is to melt the solder paste into liquid by internal heating to weld components and PCB pads together. The components and pads are then solidified together by cooling. So what are the important process requirements for reflow soldering? The following SZTech-SMT will give you a detailed introduction to the reflow soldering process requirements.

What are the factors that affect the efficiency of SMT production?

![]() May 20, 2023 | Factors that affect SMT production speed

Abstract: During the SMT pick and place process, the work efficiency of the placement machine determines the production capacity of the entire assembly line, so what affects the working speed of the placement machine? Taking the cantilever mounter as an example, SZTech-SMT will briefly explain it below, and hope it will be helpful to you!

May 20, 2023 | Factors that affect SMT production speed

Abstract: During the SMT pick and place process, the work efficiency of the placement machine determines the production capacity of the entire assembly line, so what affects the working speed of the placement machine? Taking the cantilever mounter as an example, SZTech-SMT will briefly explain it below, and hope it will be helpful to you!

What is the precaution for the SMT production process?

![]() May 20, 2023 | Precaution for the SMT

Preparation before production

May 20, 2023 | Precaution for the SMT

Preparation before production

What is the Job Responsibility of an SMT Operator?

![]() May 20, 2023 | The Job Responsibility of an SMT Operator?

Abstract: SMT placement is an indispensable process in the production process of electronic products. In addition to engineers and technicians who often operate SMT assembly line equipment in the SMT workshop, there are also SMT operators who mainly operate SMT placement machines. Handle some simple faults and operations to ensure smooth production. So what are the responsibilities of an SMT operator? The following SZTech-SMT will explain to you.

May 20, 2023 | The Job Responsibility of an SMT Operator?

Abstract: SMT placement is an indispensable process in the production process of electronic products. In addition to engineers and technicians who often operate SMT assembly line equipment in the SMT workshop, there are also SMT operators who mainly operate SMT placement machines. Handle some simple faults and operations to ensure smooth production. So what are the responsibilities of an SMT operator? The following SZTech-SMT will explain to you.

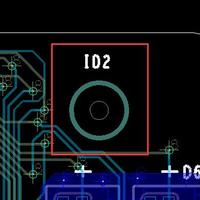

What are the design requirements for PCB Benchmark in PCBA?

![]() May 20, 2023 | design requirements for PCB Benchmark in PCBA processing

Abstract: In SMT patch processing, in order to ensure the accuracy of product patch processing, the equipment in the production line is equipped with a PCB Benchmark visual positioning system, and the reference point is also called a Mark point. The reference point (Mark) is a set of graphics for optical positioning, designed to correct the errors generated during the circuit board manufacturing process. Next, SZTech-SMT will explain to you, what are the design requirements for PCB Benchmark for SMT patch processing.

The shape of the reference point can adopt various forms that meet the requirements of SMT patch processing equipment. The reference point should be flat and there should be enough space around it. The reference points of appropriate graphics and size specifications should be selected according to the corresponding design specifications.

May 20, 2023 | design requirements for PCB Benchmark in PCBA processing

Abstract: In SMT patch processing, in order to ensure the accuracy of product patch processing, the equipment in the production line is equipped with a PCB Benchmark visual positioning system, and the reference point is also called a Mark point. The reference point (Mark) is a set of graphics for optical positioning, designed to correct the errors generated during the circuit board manufacturing process. Next, SZTech-SMT will explain to you, what are the design requirements for PCB Benchmark for SMT patch processing.

The shape of the reference point can adopt various forms that meet the requirements of SMT patch processing equipment. The reference point should be flat and there should be enough space around it. The reference points of appropriate graphics and size specifications should be selected according to the corresponding design specifications.

How to process ESD protection during SMT processing?

![]() May 20, 2023 | ESD protection during SMT processing

Abstract: ESD protection during SMT processing chip processing is a systematic project. First, establish and check the basic antistatic engineering, such as ground wires, floor mats and table mats, and environmental antistatic engineering, etc., and then configure different configurations according to different products. anti-static device. Next, SZTech-SMT will explain to you the electrostatic protection during SMT patch processing.

May 20, 2023 | ESD protection during SMT processing

Abstract: ESD protection during SMT processing chip processing is a systematic project. First, establish and check the basic antistatic engineering, such as ground wires, floor mats and table mats, and environmental antistatic engineering, etc., and then configure different configurations according to different products. anti-static device. Next, SZTech-SMT will explain to you the electrostatic protection during SMT patch processing.

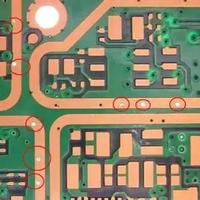

Study the reason and solutions for PCBA solder balls

![]() May 20, 2023 | The reason and solutions for PCBA solder balls

Abstract: Solder beads on PCBA are one of the main defects of SMT placement technology. Since there are many reasons for it and it is not easy to control, tin bead defects often occur. Tin beads refer to the spherical particles of different sizes formed by the solder paste leaving the PCB soldering end during the reflow soldering process and not aggregating on the pad after solidification, called tin beads. Tin balls during reflow soldering mainly appear on the sides between the two ends of rectangular chip components or between fine-pitch pins. Tin beads not only affect the product's appearance but more importantly, due to the density of PCBA processing components, there is a risk of short circuits during use, affecting the quality of electronic products. Therefore, to better control tin beads, it is necessary to do a good job of prevention and improvement in the process. Next, SZTech-SMT will briefly talk about the causes and solutions of tin beads in SMT chip processing.

May 20, 2023 | The reason and solutions for PCBA solder balls

Abstract: Solder beads on PCBA are one of the main defects of SMT placement technology. Since there are many reasons for it and it is not easy to control, tin bead defects often occur. Tin beads refer to the spherical particles of different sizes formed by the solder paste leaving the PCB soldering end during the reflow soldering process and not aggregating on the pad after solidification, called tin beads. Tin balls during reflow soldering mainly appear on the sides between the two ends of rectangular chip components or between fine-pitch pins. Tin beads not only affect the product's appearance but more importantly, due to the density of PCBA processing components, there is a risk of short circuits during use, affecting the quality of electronic products. Therefore, to better control tin beads, it is necessary to do a good job of prevention and improvement in the process. Next, SZTech-SMT will briefly talk about the causes and solutions of tin beads in SMT chip processing.

What are the reasons for cold welding in PCBA processing

![]() May 20, 2023 | The reasons for cold welding

Abstract: During the reflow soldering process of PCBA processing, the welding defects caused can be mainly divided into two categories. The first category is related to metallurgy, including cold welding, non-wetting, silver migration, etc.; the second category is related to abnormal solder joint morphology. , including tombstoning, offset, wicking, bridging, voids, solder balls, insufficient solder paste volume and weak or open circuits, grainy surfaces, etc. Today SZTech-SMT will explain to you the reasons and solutions for cold welding in PCBA processing. Cold soldering refers to the phenomenon that the solder paste on the soldering end of the PCBA is not fully melted and reflowed. If granular solder joints appear, the surface of the solder joints is not smooth and irregular, or the metal powder is completely melted, it is referred to as cold welding in SMT processing. The cause analysis and solutions of cold welding are as follows:

May 20, 2023 | The reasons for cold welding

Abstract: During the reflow soldering process of PCBA processing, the welding defects caused can be mainly divided into two categories. The first category is related to metallurgy, including cold welding, non-wetting, silver migration, etc.; the second category is related to abnormal solder joint morphology. , including tombstoning, offset, wicking, bridging, voids, solder balls, insufficient solder paste volume and weak or open circuits, grainy surfaces, etc. Today SZTech-SMT will explain to you the reasons and solutions for cold welding in PCBA processing. Cold soldering refers to the phenomenon that the solder paste on the soldering end of the PCBA is not fully melted and reflowed. If granular solder joints appear, the surface of the solder joints is not smooth and irregular, or the metal powder is completely melted, it is referred to as cold welding in SMT processing. The cause analysis and solutions of cold welding are as follows:

Study The Operation Of Wave Soldering Machine From SZTech-SMT | SZTech-SMT

![]() Apr 18, 2023 | Operation Of Wave Soldering Machine, Let's take a look at the detailed operation process of wave soldering.

Apr 18, 2023 | Operation Of Wave Soldering Machine, Let's take a look at the detailed operation process of wave soldering.

Click To Know What Is The Meaning Of Wave Soldering Machine | SZTech-SMT

![]() Apr 18, 2023 | Meaning Of Wave Soldering Machine

Apr 18, 2023 | Meaning Of Wave Soldering Machine

Study Wave Soldering Machine Maintenance From SZTech-SMT | SZTech-SMT

![]() Apr 18, 2023 | wave soldering machine maintenance

Wave soldering machine maintenance. When the equipment runs long, the solidified rosin oil, flux, and other organic chemical or inorganic pollutants adhere to it. In order to better avoid the secondary pollution of the PCB and ensure the smooth implementation of the process, it is necessary to maintain and clean the machine equipment accessories on time. Usually, it is carried out on a regular basis according to the specific conditions of production and manufacturing, such as daily, weekly, monthly, quarterly, etc. The relevant content is for reference:

Apr 18, 2023 | wave soldering machine maintenance

Wave soldering machine maintenance. When the equipment runs long, the solidified rosin oil, flux, and other organic chemical or inorganic pollutants adhere to it. In order to better avoid the secondary pollution of the PCB and ensure the smooth implementation of the process, it is necessary to maintain and clean the machine equipment accessories on time. Usually, it is carried out on a regular basis according to the specific conditions of production and manufacturing, such as daily, weekly, monthly, quarterly, etc. The relevant content is for reference:

How To Use SMT Feeder Correctly? | SZTech-SMT

![]() Apr 18, 2023 | How to use SMT Feeder correctly? View the blog from SZTech-SMT to use and manage your feeder in an accurate way!

Apr 18, 2023 | How to use SMT Feeder correctly? View the blog from SZTech-SMT to use and manage your feeder in an accurate way!

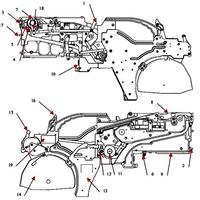

Drawing of the SMT feeder, know more from drawing! | SZTech-SMT

![]() Apr 18, 2023 | Detail drawing of the SMT feeder from SZTech-SMT, check the below blog to know how to call it!

Apr 18, 2023 | Detail drawing of the SMT feeder from SZTech-SMT, check the below blog to know how to call it!

What Are The Environmental Requirements For The SMT Factory? | SZTech-SMT

![]() Apr 18, 2023 | Environmental requirements for the SMT Factory?

Apr 18, 2023 | Environmental requirements for the SMT Factory?

What are the Advantages and disadvantages of BGA at SMT | SZTech-SMT

![]() Apr 18, 2023 | Advantages and disadvantages of BGA at SMT

Apr 18, 2023 | Advantages and disadvantages of BGA at SMT

- SMTnet

- »

- SMT, PCB Electronics Industry News

- »

- SZTech-SMT Firm

- »

- SZTech-SMT Firm News

.gif)