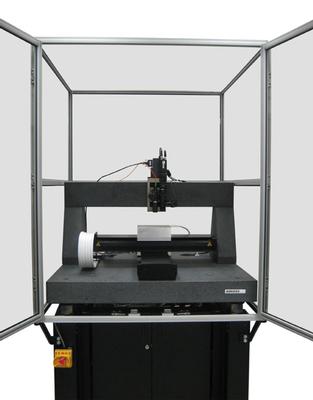

NANOVEA HS1000

Model: |

NANOVEA HS1000 |

Category: |

|

Model Year: |

2011 |

Condition: |

|

Value: |

$ 100000.00 |

Location: |

USA |

Offered by: |

|

| Contact Supplier |

Nanovea Automated Optical Inspection (AOI) utilizes leading edge optical pens using superior white light axial chromatism. Nano through macro range is automatically obtained during measurement (Profile Dimension, Roughness Finish Texture, Shape Form Topography, Flatness Warpage, Volume Area, Step-Height Depth Thickness and others) on a wider range of geometries and materials than any other vision or laser based optical inspection system. With the use of a large range of optical pens optical inspection can precisely measures an endless range of applications. Nanovea optical inspection has zero influence from sample reflectivity, variations require no sample preparation and have advanced ability to measure high surface angles. Easily measure any material: transparent, opaque, specular, diffusive, polished, rough etc. Unlike other optical measurement techniques, large surface areas can be precisely measured without any imaging stitching. Nanovea Profilometers can be built with custom size, speeds, scanning capabilities, Class 1 Clean Room compliance, with Indexing Conveyor and for Inline or online. *For further specifications contact Nanovea directly.SYSTEMS & SOFTWARE

HS1000 Profilometer | Automated Optical Inspection

Automated Optical Inspection at speeds 50 times faster than most inspection systems in its class. Inspection speeds can reach up to 1m/s and data acquisition up to 31KHz providing crucial inspection for more time constraint production and quality control environments. The HS1000 is made mostly of granite to provide superior stability and comes with an optional enclosure workstation to create a fully contained stand-alone instrument. The HS1000 can also be equipped with an 180point line sensor to make inspection up to 180 times faster, which gives 1m/s stage speed and an acquisition rate up to 324,000. Ideal option for hi-speed automation and quality control environments. Optimized versions of the HS1000 Profilometer has been built for Photovoltaic, Microelectronics and Asphere production environments. Capable of hih speeds, acquiring up to 31,000 points per second and scan areas up to 1m x 1m. Measurements can range from microelectronic planarity, to solar cell flatness to aspheric topography and dimension. Available as stand alone or inline for integration production lines for quality control inspection.

• Hi-Speed • Automated • User Friendly Technology • (PRVision) Image Pattern Recognition • Enhanced Granite Structure • Safety Enclosure Workstation • Indexing Conveyor or Inline Integration Option • 31,000 points per second and scan areas up to 1m x 1m for inline quality control

Software | 2D Pattern Recognition & 3D Analysis

PRVision automatically recognize features from a user-trained image file. The surface is scanned while automatically recognizing all features of interest; then either automatically measures every feature found or a select few that are chosen by the user. PRVision can also be used to reference sample orientation during a Macro measurement, which will automatically correct for rotations or displacement created when samples are loaded and unloaded from their holder. This option will significantly reduce setup time when a surface pattern or if several samples will be measured. The Nanovea 3D software is the acquisition software used for further analysis. The software permits the user to define the size of the area, or line to be measured, as well as the lateral resolution of the measurement. The software also allows three different views of the measurement in real-time: cross-sectional, top-down and 3-dimensional views. To make it easier to find and measure small surfaces, a re-centering function allows the user to point-and-click on the scanned image in order to re-center the next scan to that specific point; or by use of a point-and click feature from an optional offset video camera. Combining these two functions allows the ability to automatically detect features and defects, remembering their location, then having the ability to measure that area in 3D. The 2D and 3D data can be used to compare dimension, shape, roughness, volume and much more to predefined pass/fail parameters.