Ersa ETS 330 Mini Wave Soldering Machine

Company Information:

Name: |

Ersa ETS 330 Mini Wave Soldering Machine |

Category: |

|

Offered by: |

|

Ersa ETS 330 Mini Wave Soldering Machine Description:

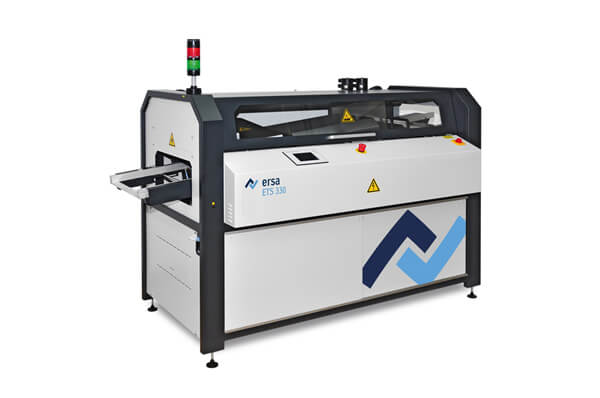

Ersa ETS 330 Mini Wave Soldering Machine

Ersa ETS 330 -Mini Wave Soldering Machine

small Wave Soldering Machine

Ersa ETS 330

Mini Wave Soldering Machine

Product description: Ersa ETS 330 Mini Wave Soldering Machine

Ersa ETS 330 Mini Wave Soldering Machine

A compact wave soldering system for the industrial manufacture of small to medium production volumes

Inline-capable dual wave soldering systems with 330 mm maximum working width and code operation

Precise and economic flux deposition on account of a freely defined spray area

Powerful preheat with 900 mm length protected by a glass ceramic (ceran glass) cover

Additional and programmable length of stay over the preheater for assemblies requiring more heat

Ideal combination of solder nozzles for all applications

Robust conveyor system with forced guidance of the pallet

Modern controls with a graphic user interface and touch-screen

Automatic heat-up with weekly time clock

Large solder program library with up to 199 different programs

Ersa ETS 330 -Mini Wave Soldering Machine

The Ersa ETS 330 is a microprocessor controlled Wave Soldering System to process boards populated with SMD and through-hole components up to a board width of 330 mm. The ETS 330 is ideal for the use with low-solid fluxes. The ability to store 199 programs, the clear text entry of all process relevant parameters and the self-monitoring function of the system ensure a high degree of repeatability.

Dimensions

Length approx. 2,000 mm

Width approx. 890 mm

Height approx. 1,400 mm

Conveyor systems

Pallet conveyor

Maximum conveyor speed: 2,5 m/min

Maximum working width: up to 330 mm

Media supply

Compressed air

Electrical power

Exhaust

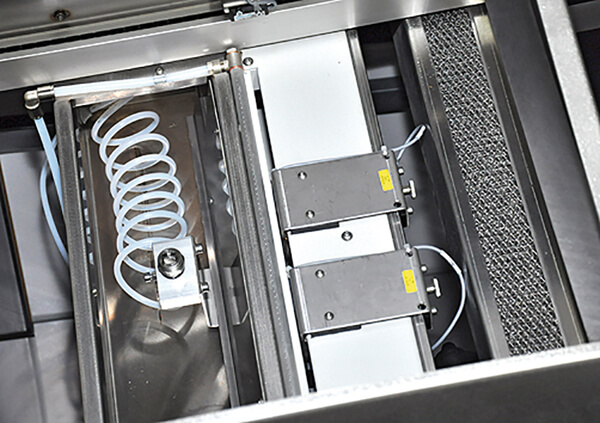

Preheating

Heat transfer via medium and short wave radiation

Length of preheat: approx. 900 mm

Solder module

Depending on the alloy used, solder content is between 360 to 410 kg

Options:

FOCUS spray fluxer

Short wave emitters

Dual wave solder module with pre-solder nozzle (SMD nozzle)

Prolongation of preheat through dwelling oft he PCB over the preheater

Solder level monitoring

Exhaust monitoring

Touch-operation terminal

Weekly time clock

Cooling unit after soldering

Infeed and exit extensions

Keywords:

Professional SMT machine supplier. If you have any needs, please contact us.

Hanwha Pick and Place Machine:XM520, HM520, HM510, Excen PRO, Decan S2, Decan S1, SM485P, SM482 Plus, SM481 Plus, SM471 Plus

Yamaha Pick and Place Machine: YRM20DL, YRM20, YSM40R, YSM20R, YSM20WR, YSM10, F8S, YS12F, YG12, YG100RA, YS24F

JUKI Pick and Place Machine: LX-8, RX-8, RX-7R, RX-7, RS-1R, RS-1, RS-1XL,JM-20, JM-100, FX-3RA, KE-3010A, KE-3020VA

Panasonic Pick and Place Machine: NPM-GH, NPM-DX, NPM-D3A, NPM-D3, NPM-WX/WXS, NPM-TT2, AM100, VM101, VM102

FUJI Pick and Place Machine: AIMEX III, AIMEX R, NXT III, NXTR-S, NXTR-A, NXT M6 III, NXT M6 Ⅱ, NXT M3 III, NXT M3 Ⅱ,

Siemens Chip Mounter: SIPLACE XS Series, SIPLACE SX Series, Siplace DX Series, SIPLACE TX Series,

SMT Stencil Printer: GKG, DEK, JUKI, FUJI, Yamaha, Panasonic, SMT Glue Dispenser, Semi-Auto stencil printer,

SMT Reflow oven: 6 Zones, 8 Zones, 10 Zones, 12 Zones, Heller, Ersa, JT

Insert Plug-in machine: Hanwha, JUKI, Yamaha, Panasonic, Offline Insert Plug-in machine, Vertical Plug-in machine, Heterotypic Plug-in machine

Wave Soldering Machine: Dual Rail, lead free, Nitrogen, Ersa, JT

SMT Inspection machine: Saki SPI/AOI, Koh Young SPI/AOI, JUKI SPI/AOI, Omron SPI/AOI, Yamaha SPI/AOI, Flying Probe Testing Machine, X-Ray Inspection Machine, In-Circuit Tester,

SMT Peripheral Equipment: PCB Loader, PCB Unloader, PCB Conveyor, PCB Transfer Shuttle Conveyor, Auto BGA Rework Station, PCB loader Buffer Stocker, PCB Cleaning Machine, SMT Nozzle Cleaning Machine, PCB Separator Depanelizer Machine, Automatic inline Labelling Machine, SMT Screen Developing and Stripping Machine, SMT Ionic Contamination Tester, SMT Camera Module Cleaning Machine, Reflow Oven Cooler Cleaning Machine, SMT Fixture Cleaning Machine, PCB Stencil Cleaning Machine, PCB Laser Marking Machine, PCB Circuit Repair Machine, Thermal Profiler for reflow oven,

SMT Spare Parts: JUKI Feeder, Yamaha Feeder, Panasonic Feeder, Sansung/Hanwha Feeder, FUJI Feeder, Seimens Feeder, Mydata Mycronic Feeder, Feeder Storage Cart, Tray Feeder, Feeder Calibration jigs, JUKI Nozzle, Yamaha Nozzle, Panasonic Nozzle, Samsung/Hanwha Nozzle, FUJI Nozzle, Universal GSM Nozzle, Siemens SIPLACE ASM Nozzle, Mydata Nozzle, JUKI Spare parts, Yamaha Spare parts, Panasonic Spare parts, Samsung/Hanwha Spare parts, Siemens Spare Parts, FUJI Spare Parts, Mycronic Spare Parts,

SMT WORKSHOP LINE: SMT LOADER+ SMT printer+ SMT SPI+ SMT chip mounter+ SMT reflow oven

Add: No. 4, Yangyong Industrial Zone, Shapu Community, Songgang Street, Baoan District, Shenzhen China Tel: +86 -137 14564591 Skype:sales@effsmt.com E-mail:sales@effsmt.com

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is English manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / phone /Wechat online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

Ersa ETS 330 Mini Wave Soldering Machine was added in Jan 2024

Ersa ETS 330 Mini Wave Soldering Machine has been viewed 10 times

20 More Products from Efficient Technology Co., Ltd :