Fully Automatic Glue Spraying Machine for Honeycomb Panel PVC Sandwich Panels

Company Information:

Name: |

Fully Automatic Glue Spraying Machine for Honeycomb Panel PVC Sandwich Panels |

Category: |

|

Offered by: |

|

Fully Automatic Glue Spraying Machine for Honeycomb Panel PVC Sandwich Panels Description:

The glue Spraying line is based on the reform of the traditional roller glue machine process. With the marketization and standard scale of stainless steel furniture, all-aluminum furniture, and whole-house customization, the demand for new building materials is increasing day by day. In order to better meet the market According to the needs of customers, the functions are constantly upgraded and updated. In the building materials composite industry, the problems faced by customers are the diversification of products, the personalization of sizes and the huge quantity. The basic functions of this equipment are:

1.Automatic edge finding: (automatic recognition) automatically adjusts the glue spraying position according to the size and length of the board;

2. Automatic glue amount: (automatically adjusts the speed of glue dispensing according to the size of the board and the conveying speed);

3. Automatic feeding: When the glue volume in the glue barrel is lower than the set lower limit, the glue adding process will be automatically started.

4. One-click start: Eliminate the tedious preparation work before starting up, and realize automatic operation to working status with one click;

5. Glue heating: The equipment is equipped with glue heating and heat preservation functions, so that the glue is not restricted by ambient temperature and region, allowing customers to choose the brand of glue more freely;

6. Anti-sedimentation mixing: A glue barrel is equipped with an intelligent control mixing device to prevent precipitation or stratification caused by long-term stasis of glue, and to ensure that the glue is heated evenly when heated.

7. Visual mixing: The equipment adopts imported dynamic mixing tubes and is matched with Taiwan's high-speed brushless motor to achieve adjustable mixing speed and direct viewing of the mixing status to ensure uniform mixing;

8.Disassembly-free automatic cleaning: The equipment adopts a high-pressure gas-liquid automatic switching cleaning device. There is no need to disassemble the glue spray head, achieving true disassembly-free cleaning in the industry, and the cleaning effect is visible to the naked eye;

9.Patented glue-controlled suction valve: The equipment is equipped with our company's patented glue-controlled anti-drip suction valve, which can open the glue in time and close the glue quickly with suction adjustment;

10.Special metering pump: The equipment adopts a special polyurethane high-flow and wear-resistant precision metering pump , which can accurately control glue and adjust the flow rate to achieve an accuracy of ±0.5%, effectively avoiding inaccurate proportions and greatly improving the product qualification rate;

The overall cold plate bending process of the equipment +special industrial profiles ensure smooth operation, beauty and elegance. The conveyor line adopts German friction transmission method, which can realize stop and start, automatically adjust the conveying tension, and realize glue dispensing without gaps and noise;

The swing arm adopts a high-speed module for reciprocating spray coating and is equipped with a precision servo motor to effectively and accurately control the glue spraying position and leave a reasonable margin to prevent glue from overflowing)

Product Description

This solution describes how XPS Insulation boards are produced. Using the method of one-component/two-component polyurethane glue coating, coating the MGO board with XPS board, coating it again, then placing the MGO board to form a sandwich structure, and finally waiting for the glue to solidify by cold pressing.

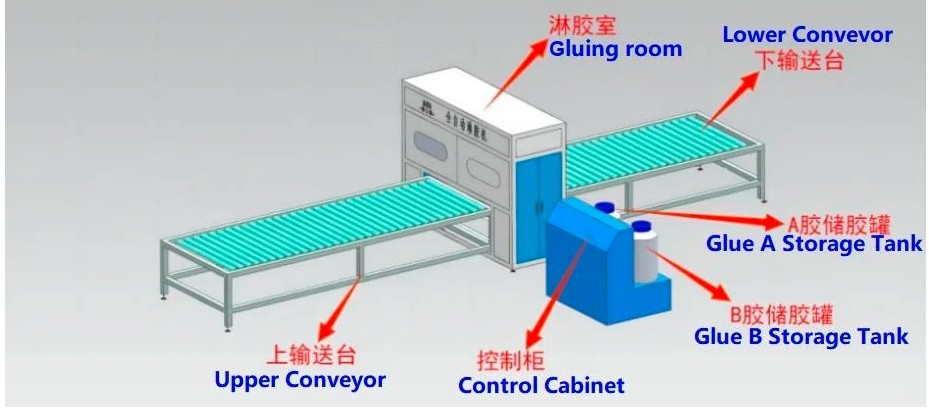

CONSTRUCTION

The machine consists of a return glue spraying system with a spray head and a movable glue feeding mechanism, it has a frame structure, spray head is movable, and there is numerical control (CNC). The machine is equipped with a fault warning system (overload, emergency shutdown, phase break protection, voltage surge protection).

APPLICATION

Machine is designed for rapid uniform application of glue onto large areas during production of composite panels for different fields: automotive industry (panels for trailers and FRP panels for refrigerated wagons), car building, construction materials (fire-resistant doors, thermal panels, fireproof screens made of mineral wool), furniture production (including kitchen and paper panels, etc.).

FEATURES

Advanced control process, easy operation, measurement accuracy, uniform glue distribution, precise positioning, self-cleaning function. Intelligent determination of length and width of the product, precise laser positioning, adjustment of glue volume and spray speed ratio with touch of a button. The machine is equipped with a buffer heater that continuously heats the panel without stopping and shifting, thus ensuring continuous production.

Model KPD-1300L (standard)

Dimensions of spraying chamber: 1300mm *6000mm h . 1) Rubberized roller with a stroke length of 3 meters; roller movement can be adjusted according to production needs. 2) Transportation tape with individual dimensions. Upon request of the customer, glue tank can be placed above the tape on a special shelf or next to the machine.

Model KPD-2000L(reinforced)

Dimensions of spraying chamber: 1600x6000mm. 1) Rubberized roller with a stroke length of 3 meters; roller movement can be adjusted according to production needs. 2) Transportation tape with individual dimensions. Reinforced frame, which allows you to place a container with glue on the top of the machine by placing the vinyl container on a two-layer bracket. Glue is automatically weighed thanks to the weight sensor; there is an automatic reminder function for glue refill.

2. Machine TDS

ModelKPD-1300LGoverning equationVelen Touch Screen + Mitsubishi Programmable ControllerPower supply220V 50HZPneumatic0.5MPa-0.8MPaEquipment power2780WCountertop Height800MM±50hybrid approachHigh speed dynamic mixing 100-3000 rpmMeasurement methodIndustrial computer + Mitsubishi PLC + precision metering pump + precision glue control valveProportioning accuracy100g±1%Accurate2g ± 1 per cent per squareGluing speed0.5g-40g/secOverall dimensions9000-2250*1750 (rated according to model)ConfigureGlue heating, automatic gluing, automatic cleaning, automatic identification, sedimentation mixing, glue shortage alarm, etc.Equipment weight1000KG(reference weight)

3. Honeycomb equipment has several advantages:

• Automatic gluing

• Reducing labor cost

• High efficiency

• Energy saving and emission reduction

4. Applications:

• Making aluminum honeycomb core

Aluminium honeycomb panel

Copper honeycomb panel

Stainless steel honeycomb panel

FRP honeycomb panel

HPL honeycomb panel

Aluminium foam core sandwich panel

FRP foam core sandwich panel

FRP plywood panel

Please contact by email: gluepotting@gmail.com

Whatsapp+86 134 2516 4065

Fully Automatic Glue Spraying Machine for Honeycomb Panel PVC Sandwich Panels was added in Apr 2024

Fully Automatic Glue Spraying Machine for Honeycomb Panel PVC Sandwich Panels has been viewed 7 times

20 More Products from Kapton Automation Equipment (Guangzhou) Co., Ltd :

1.jpg)