2component epoxy Potting machine for Car door switch sensors potting and encapsulation

Company Information:

Name: |

2component epoxy Potting machine for Car door switch sensors potting and encapsulation |

Category: |

|

Offered by: |

|

2component epoxy Potting machine for Car door switch sensors potting and encapsulation Description:

2component epoxy Potting machine for Car door switch sensors potting and encapsulation

epoxy resin dispenser machine two-component adhesive coating mixing dispensing 10/1 ab glue filling machine

Automatic glue mixing machine is mainly used for a two-component glue( Epoxy/ Silicone/PU,etc adhesive), automatic metering and mixing the ratio by two sets of high precision pumps, supply to a fully mixing design and then dispensing , dosing , dispensing the aimed products

Epoxies, silicones and polyurethane are among the most frequently used potting compounds. These can be applied to

PCBs,PCBA,capacitors,power electronics, LED lighting, sensors, and more. Some of the desired properties include good

adhesion,excellent electrical insulation, thermal stability, super chemical resistance, low shrinkage upon curing, an appropriatecoefficient of thermal expansion (CTE), and suitable viscosity for the specific application. Formulations can be blended toprovide a balance of these and other properties through careful selection of resin, agent, and fillers.

Epoxies, silicones and polyurethane are commonly used with fillers to lower shrinkage, enhance dimension stability, and improve abrasion resistance. The use of fillers is the critical factor for obtaining thermal conductivity while retaining electrical resistance.

Besides ,the liquid potting material must flow easily so that it completely covers the component, leaving no voids. If air becomes trapped in the housing, the moisture it contains may cause corrosion - eventually leading to component or product failure.

OUR equipment with pre-heat functions that helps the pre-heat the AB compound in tank in advance to keep a good flow-ability.Good liquidity helps resin flow into product easily and evenly.

OUR machine with tank stirring vacuum degas functions ,which can help compounds to remove air bubble easily and arrived the good potting status .

Removing air bubbles is very important.Vacuum degassing remains a critical processing step. The best technique for vacuum degassing is referred to as "bumping degas" which is alternately pulling and relaxing a vacuum in 30- to 60-second cycles.

FEATURES AT A GLANCE

1. Vacuum material-feeding system or diaphragm pump feeding system

2. High precision pump metering system

3. Dynamic/Static mixing system

4. Three-axis motion system

5. Programming control system

6. Heating function

7. automatic cleaning function.

High-quality motion components

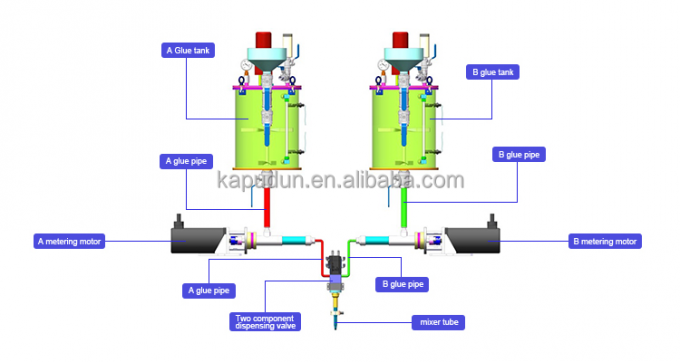

Working principle

The machine will have two tanks for keeping Liquid A & B separately.

There are two sets of metering pumps inside the machine, draining out liquids individually from tank A & B. Liquid A & B mix with each other in the mixer pipe and dispensed out according to the programmable data .

PRODUCT SPECIFICATIONS

|

Models: |

KPD-500 Automatic Multifunctional Glue Potting Machine |

|

Suitable process: |

It can be used as a stand-alone machine or with the customer’s original assembly line to achieve on-line gluing. |

|

Proportion of glue: |

10:1 – 1:1 |

|

hybrid approach: |

Dynamic stirring mixing/static |

|

Machine Stroke: |

500x500x100mm |

|

speed |

X,Y axle 400mm/s |

|

accurate |

±0.05mm |

|

Programme stock: |

999 |

|

programmer |

Teach-In Programming |

|

metrological: |

High precision metering pumps |

|

control method: |

PLC+touchscreens |

|

input method: |

Touch screen + buttons + IO |

|

Appearance Material: |

Industrial square tube welding + 6061 alloy + cold rolled plate |

|

Drum size: |

A barrel 30L, B barrel 10L (can be customised) |

|

External Dimensions: |

1100×1350 X1600mm |

|

Gum flow rate: |

1–80g/5sec (customised large glue volume available) |

|

trajectory: |

Punching points, walking straight lines, curves, drawing circles, arcs, squares, and other irregular shapes. |

|

Supply Voltage: |

AC220V/50HZ |

SALES AND SERVICE NETWORK

Successful Project

More sucessful project

1.Potting&Dispesing&Casting: electronics componnets , PCB board, Capacitor, power supply, transformer, ignition coil, reversesensor, circuit board, filter products ,underwater parts, electronic ballast ,aviation parts, aerospace parts....

Transformer , capacitance , power module , regulating plate ,protection module , generator , pressure package , soli relay ,fault indicator , Sensors , junction box , clutch , wave filter , water meter , boattery cover , rectifier and so on

.2Dispensing&Dosing : LED strip , led lamp , led bulb , aluminum,led screen , display module ,medical parts,medical liquid filling...

3.Bonding&doming : LCD screen ,LOCA bonding,ABS plastic,different types of stickers , badge , keychains , souvenirs ,arts , photo frame , and other arts graphics....

2component epoxy Potting machine for Car door switch sensors potting and encapsulation was added in Mar 2024

2component epoxy Potting machine for Car door switch sensors potting and encapsulation has been viewed 9 times

20 More Products from Kapton Automation Equipment (Guangzhou) Co., Ltd :

1.jpg)