Rigid-flex PCB assembly

Company Information:

Name: |

Rigid-flex PCB assembly |

Category: |

|

Offered by: |

|

Rigid-flex PCB assembly Description:

Rigid-flex PCB assembly

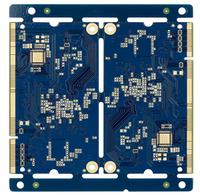

Rigid-flex PCB is a new type of printed circuit board with the adaptability of a flexible PCB and the durability of a rigid PCB.. Among all types of PCBs, the combination of rigid PCB and flexible PCB is the most resistant to harsh environmental applications, so it is favored by industrial control, consumer electronics, medical, and military equipment manufacturers.

Just as the name implies, a rigid-flex PCB is a standard rigid board attached to a flexible PCB during the PCB assembly process. The flexible portion is usually used to connect the main rigid PCB to other boards or another device in post-production, or to satisfy the shape or space constraints.

The difference in the rigid-flex PCB assembly process

The SMT process of rigid-flex PCB assembly is the same with the rigid PCB and the flexible PCB because they all need to pass the solder paste soldering process, component placement, and reflow soldering. However, there are some unique points should be considered for rigid-flex PCBs. It will prevent great trouble if these additional requirements can be fulfilled in the assembly process.

- Solder paste process

- SMT components placement

- Reflow process

As the same with the rigid PCB, the solder paste is applied to the rigid-flex board through the operation of stencil and solder paste printer. But workers are plagued by the size and vulnerability of the board in the process. Unlike rigid boards, the flexible board’s surface is not smooth, which means it needs to be held in place by fixtures and positioning holes. Besides, flexible materials are not stable in size and will extend or fold with the changes in temperature and humidity. For this reason, rigid-flex PCB assembly often requires smaller carriers than rigid board.

Compared to the rigid PCB manufacturing, the manufacturing process of the rigid-flex PCB is a little complex and time-consuming. But rigid-flex PCBs own obvious advantages such as more light, flexible size, more reliable connection, dynamic, and mechanical stability, etc. he characteristics of the rigid-flex PCB determine its application area covering the entire application area of FPC, and rigid-flex PCB is becoming an essential direction for the development of the PCB industry. The demand of Rigid-flex PCB manufacturing and assembly prototype is also increasing quickly.

Rigid-flex PCB assembly was added in Sep 2021

Rigid-flex PCB assembly has been viewed 367 times

8 More Products from NextPCB-Reliable Multilayer Boards Manufacturer :