Wave solder pallets Cleaning Machine-SME-5200

Company Information:

Name: |

Wave solder pallets Cleaning Machine-SME-5200 |

Category: |

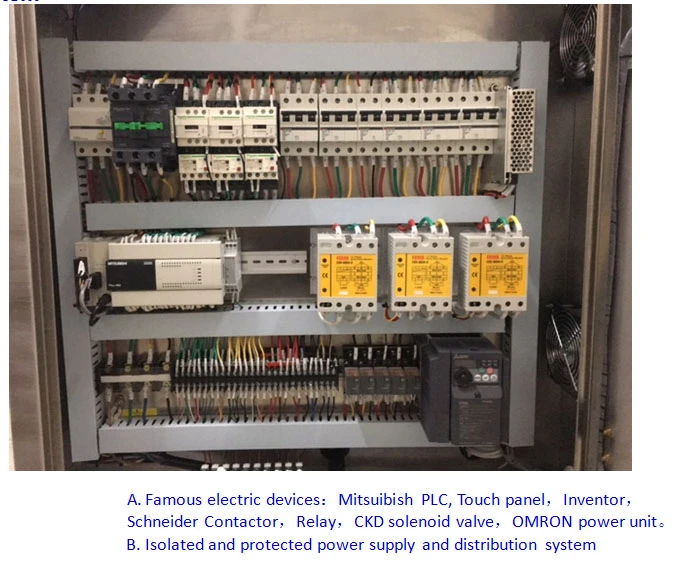

|

Offered by: |

|

Wave solder pallets Cleaning Machine-SME-5200 Description:

-

contact: jacky.li@samtronik.com

-

www.sam-smt.com

| Categories | Wave pallet cleaning machine |

|---|---|

| Album | View larger image |

| Brand | SAMTRONIK |

| Model | SME-5200 |

| FOB port | Shenzhen |

| Terms of Payment | L/C, D/A, D/P, Western Union, T/T |

| Download DOC |  |

| Update Time | 2020-11-16 |

Contact Now

Favorites

DETAIL INFORMATION

Fixture Cleaning Machine-SME-5200

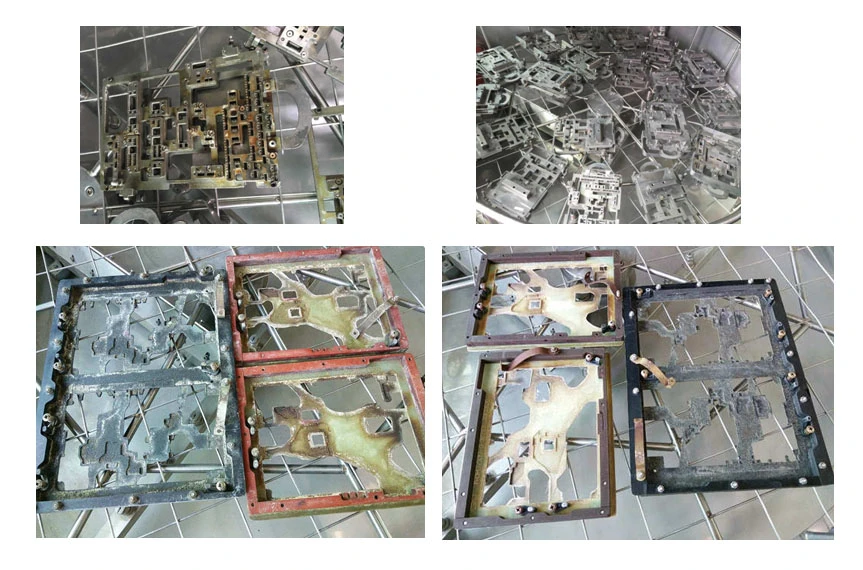

SME-5200 Fixture Cleaning Machine is used to clean grease, flux, dusts on the surface of all kinds of SMT fixtures,tray, reflow oven cooler and filter, wave-soldering oven claw, chains, and nets…etc.

SME-5200 is made up of wash unit, rinse unit, dry unit, rotation cleaning basket unit and control unit. Put the dirt SMT fixtures on to the cleaning basket, setting the cleaning parameters, the machine will automatically complete wash, rinse and dry process by just pushing start key. The fixtures after cleaning is very clean and dry, ready to use at any time.

Features:

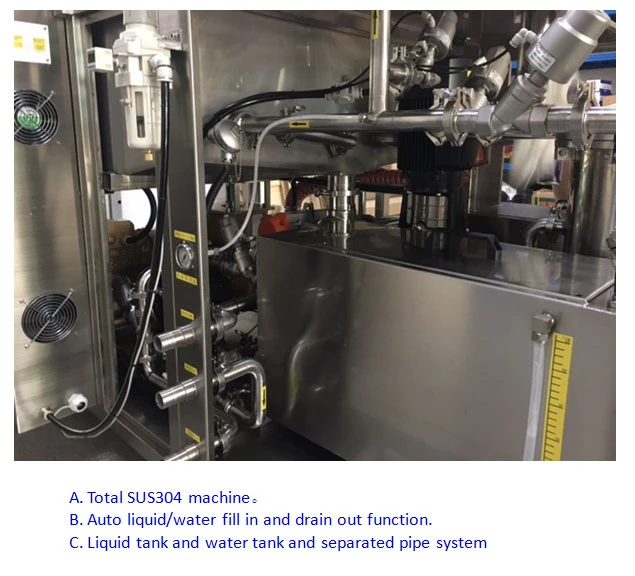

1, Total SUS 304 structure, resist Acid and Alkali corrosion, firm and attractive.

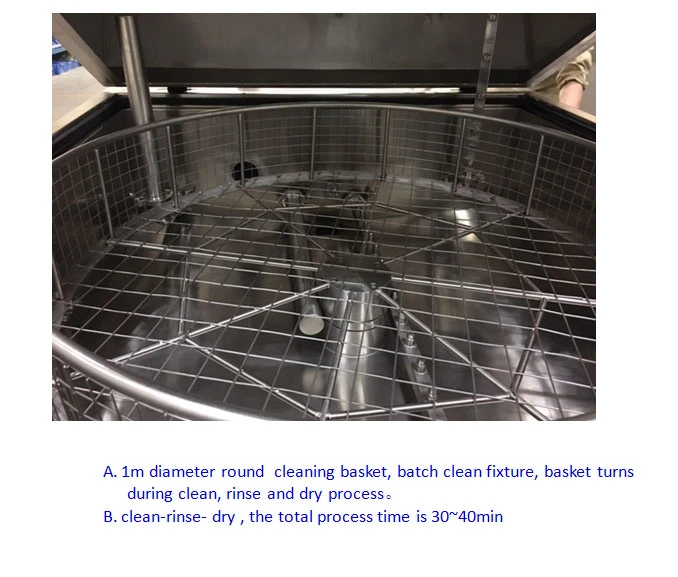

2, 1 meter diameter big cleaning round basket, can clean 20~40 pcs fixtures at one time.

3, Clean liquid spray from 3 spray rods on upper/lower and front side, cleaning basket rotates during cleaning.

4, Clean liquid pressure up to 6kg/cm2, make it throughly clean of whole fixture.

5, PLC program control, Touch-panel operation,cleaning parameters can be set and change conveniently.

6, Easy One-button operation, high pressure clean+ rinse+ hot air dry, all process complete in a cycle automatically.

7, Clean liquid and water heat and temperature keeping function.

8, Closed-loop clean and rinse, clean detergent and rinse water are cycling filtered and reused in the machine.

9, Standard equipped solution and water auto fill in and discharge function.

10,The fixtures are clean and dry after cleaning, standby and ready for use at any time.

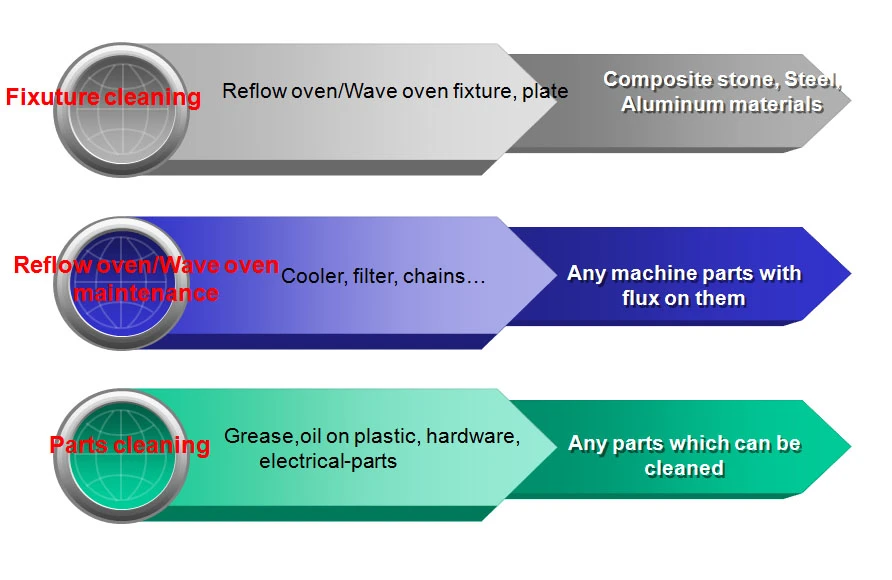

Cleaning Obojects

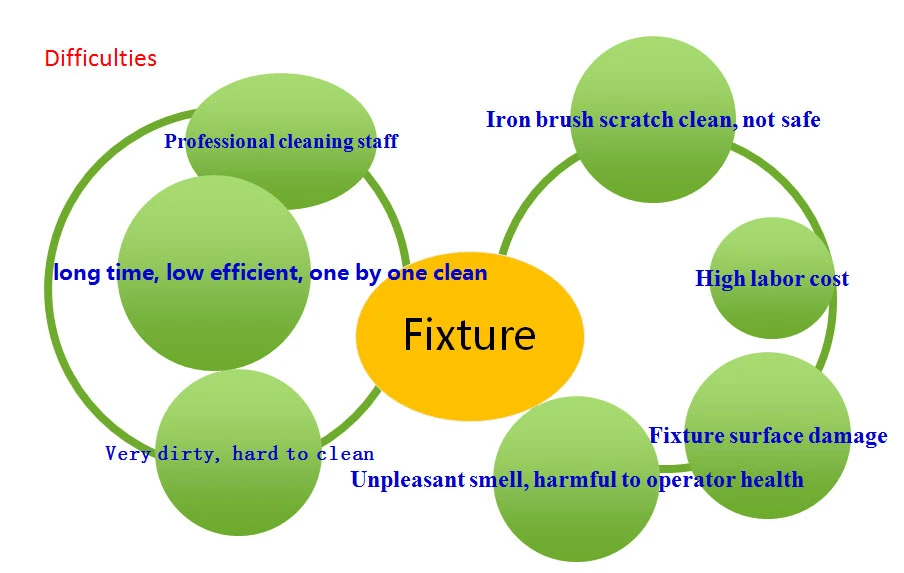

Fixture Manual cleaning difficulties

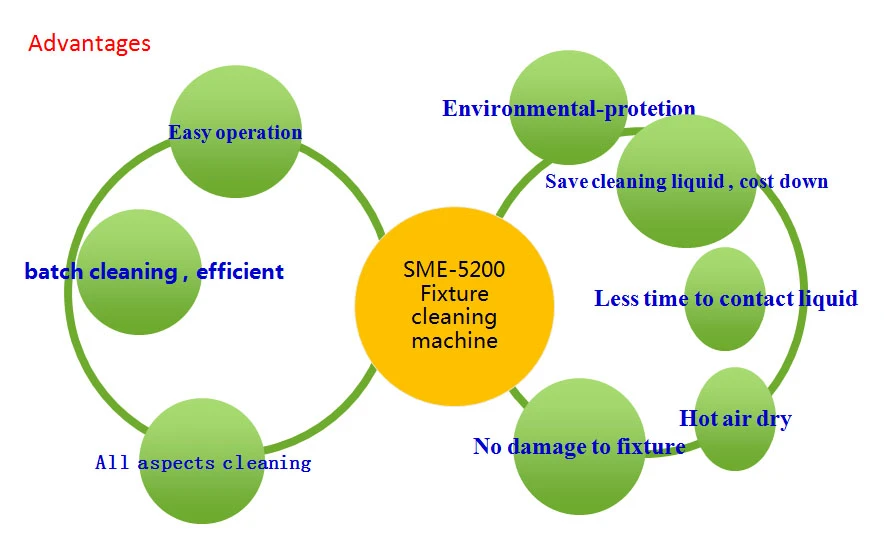

Machine Auto Cleaning Advantages

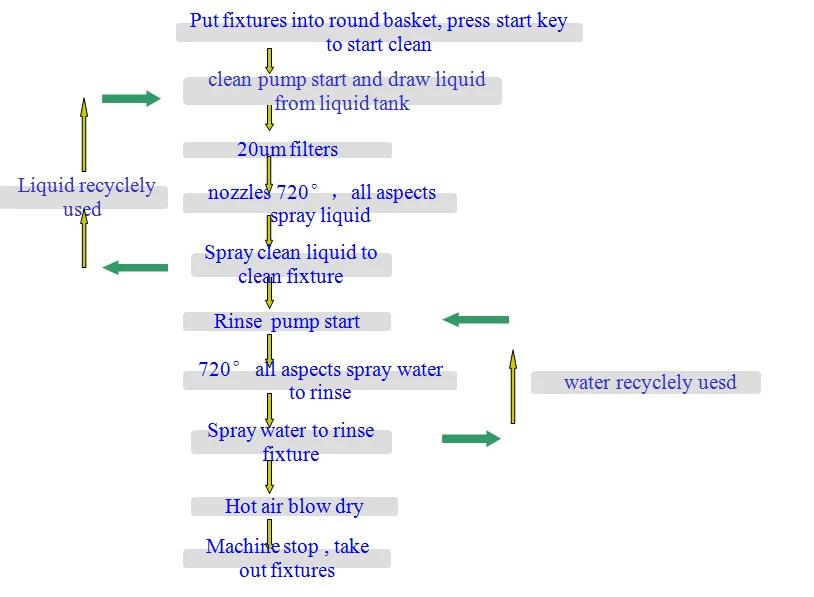

Fixture cleaning process flow chart:

Specifications:

|

Item |

SME-5200 Spec |

|

Cleaning basket size |

Φ1000mm x H 200mm. Special size option |

|

Spray unit |

Upper/lower/front side,720°all-around spray |

|

3-level filter system |

1mm /50um/20um filters |

|

Clean tank capacity |

80L |

|

Rinse tank capacity |

80L |

|

Clean spray pressure |

5~6 kg/cm2 |

|

Clean time |

5~15 Min |

|

Rinse time |

1~3 Min |

|

Dry time |

10~20Min |

|

Clean detergent heat temp |

Room temp~80℃ |

|

Rinse water heat temp |

Room temp~80℃ |

|

Hot air heat temp |

Room temp~90℃ |

|

Clean pump power |

2.2KW |

|

Clean detergent power |

9KW |

|

Hot air heat power |

9KW |

|

Air blower power |

4.0KW |

|

Air supply |

0.5~0.7Mpa |

|

Power supply |

3 P,AC 380V,50/60HZ,33KW |

|

Machine size |

L1380 x W2100 x H 1400 (mm) |

|

Machine weight |

500KG |

Description:

1.Cleaning Basket

2. Pumps and air blower

3.Liquid tank/water tank/SUS304pipes/auto liquid/water fill in and drain out function

4.Control System

SME-5200 Reflow oven cooler cleaning comparison:

SME-5200 wave oven fixture cleaning comparison:

Company Profile

About Samtronik

Samtronik is a professional one-stop SMT Equipment service provider , With more than 10 years Electronic Manufacturing Service factory Equipment selling experience .

Samtronik mainly supply pcb handling equipment ,PCB Separator ,screw locking machine , smt cleaning machine , smd counter , smd taping machine ,smt parts etc .

Why Choose Us

1.We promise customer response within 24 hours;

2. Well-trained and experienced staffs to answer all your enquires in fluent English;

3.Best products and price to offer;

4.Shortest time to delivery the products ;

5.All machine will be strictly testing before shipment;

6.OEM & ODM services offered;

7.Best Guarantee :With 1 years warranty !

Wave solder pallets Cleaning Machine-SME-5200 was added in Nov 2020

Wave solder pallets Cleaning Machine-SME-5200 has been viewed 303 times

20 More Products from Samtronik International Limited :