Toolmaker™ On-Demand PCB Fixtures. Stop tooling around! Build your own!

Company Information:

Name: |

Toolmaker™ On-Demand PCB Fixtures. Stop tooling around! Build your own! |

Category: |

|

Offered by: |

|

Toolmaker™ On-Demand PCB Fixtures. Stop tooling around! Build your own! Description:

Make your own fixtures for less than $100 in material

- Tired of waiting on expensive dedicated tooling?

- Does your current pin support system provide inadequate support of thin PCBs?

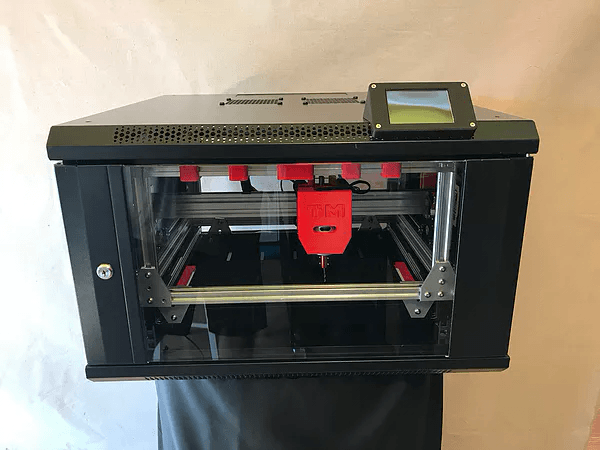

- The revolutionary TOOLMAKER™ is a mini CNC machine that develops dedicated fixtures in a material optimized for SMT applications - right there in your factory when you need them

- No programming needed. Click your PCB into the TOOLMAKER™, press start and return a couple of hours later. (Alternatively, you may download an electronic file).

- The TOOLMAKER™ simultaneously scans the bottom side of the PCB and routes a mirror image of the PCB topography into the blank material.

- The tooling accommodates the stencil printers vacuum feature

It is widely known that tooling significantly impacts various SMT processes — in particular the screen printing process. If it is affordable, the best support comes in the form of dedicated fixtures. "Afford" relates more to the several days waiting on the fixture than the $500 to $2,000 price tag that comes with each. In the on-demand manufacturing business, on-time delivery is a must and deadlines often appear ambitious if not outright unreasonable.

A popular alternative to dedicated fixtures is pin support tooling. While these products can work well for many applications, they are not ideal for all types of boards, including thin PCBs, flex circuits, odd-shaped boards, and more. There also is a maintenance issue associated with pins not firing, due to solder paste and other dirt clogging the support functions. Another concern is the lack of information about the performance of the support. SPI, placement machines, AOI and other systems provide real-time or near real-time feedback on performance. However, users are not notified about stuck pins until defects are discovered downstream.

On-Demand Fixtures

It was only a matter of time before "make it yourself when needed" dedicated tooling entered the market. Manufacturers are now able to create their own fixtures in-house whenever required. The technology is made up of two elements and uses a "mini CNC" machine concept (about the size of a large microwave oven) that carves out a mirror image of the bottom side of the assembled PCB. This fixture is carved out of a blank material designed for optimal support.

The PCB is clicked into the upper end of the machine, the blank loaded into the bottom section, the start button is pressed, and the operator can walk away. After only a couple of hours, the fixture is complete. The fixture material has a certain level of pliability, which is optimal for stencil printing and suitable for all other SMT machine tooling requirements, with the exception of reflow and wave solder, due to the high heat. Research has shown that hard tooling, like a metal dedicated fixture, is not ideal for printing. This is because of the effect on the stencil as the squeegee arrives to the are above the PCB. A certain level of give is optimal.

No Programming Required

All automatic machines first need to be programmed, right? Wrong. The fact that programming is not required for the mini CNC machine relates to a scanning technology that scores the identical negative 3D image of the assembled PCB topography simultaneously to the machine scanning the assembly. If a physically assembled PCB is not available, the user can download a 3D file of the assembly into the machine.

The smart factory trend is advancing at a snail's pace. One reason for the slow advance is the concern over data security. Most manufacturers do not want sensitive data to leave their firewalls and their control. This includes sending electronic files of their assemblies to third parties in order to build dedicated fixtures. The new capability of building fixtures in-house removes the need to share PCB assembly drawings, BOMs, etc., at least for fixture purposes. Behind every great PCB assembly is great machine tooling — especially if it is made on-demand.

Toolmaker™ On-Demand PCB Fixtures. Stop tooling around! Build your own! was added in Mar 2020

Toolmaker™ On-Demand PCB Fixtures. Stop tooling around! Build your own! has been viewed 234 times