Inline Automatic Optical AOI

Company Information:

Name: |

Inline Automatic Optical AOI |

Category: |

|

Offered by: |

|

Inline Automatic Optical AOI Description:

Inline Automatic Optical AOI For post print, pre reflow, mixed mode and post reflow applications

Leading the Way for Inspection Solutions

RISON products, can effectively control the various processes, find the solder paste printing, component placement, reflow soldering defects generated in the circuit board; Printed circuit board can rule our many common, but costly defects and greatly reduce downstream, particularly in the circuit board maintenance costs; Help increase production and increase profits; To bring you the board less maintenance, fewer discarded, less maintenance time and costs, and lower warranty and repair costs, plus higher product quality, more satisfied customers, and customer loyalty and retention.

Main Features

l For post print, pre reflow, mixed mode and post reflow applications.

l High Defect Coverage

l Acculite 4 LED rings lighting tower.

l Patented Statistic Modeling Technology.

l Unparalledled Defect Detection.

l 01005 cpabilites (with 10µ camera)

l 100% inspection: presence, absence, polarity, placement accuracy with OCV,solder joints Missing, Shift/Skew, Misalignment, Tombstone, Reverse, Polarity, Wrong Component, Bridge, Dirt/Dust, No Solder,Short Solder, Cold Solder, Lifted Lead.

l Lowest False Failure Rate.

l Intellectualized Full-color high speed digital 3CCD camera can accurately identify differences in components color tones.

l High Speed inspection.

l Quick Set-up.

l Short programming time using public library and components templates for automatic programming.

l Automatic barcode recognition

l Real time Statistical Process Control System (SPC) capability

l OCV - Optical Character Verification.

l Bad Mark.

l Automatic optimization of test path.

l Double side test in one program.

l Server Mode - Administrative data from many AOI through center server.

l Ergonometric design.

l Best Price Performance.

l CE Compliant.

|

Functional Specifications |

|

|

Test Board |

After printing, before reflow and reflow |

|

Test Method |

Many leading international algorithms such as TOC,Histogram,Match,Short,OTHER,CREST,PIN algorithms; Auto set parameters according to different test dots. |

|

Camera |

High speed industrial digital camera |

|

Resolution / Range / Speed |

(Standard) 18um/Pixel FOV: 24*15mm, Test speed<210ms/FOV |

|

Light |

Extra bright RRGB coaxial ring tower LED light(Color light) |

|

Program mode |

Manual programming, Auto frame, CAD import automatically correspond to component library |

|

Inspection items |

Absence presence, misalignment, insufficient, overflow, open, bridge, contamination; Missing, skewed, billboard, mounting on side, overturn, wrong part(OCV), damaged, reverse; Pseudo soldering etc. |

|

Special Function |

Support auto change program test, multi boards and multi program test, two sides of program test. |

|

Minimum component & pitch |

10µm:01005 chip & 0.3 pitch IC |

|

SPC and program control |

Statistics and analysis of all test data, check production and quality analysis anywhere, can output Excel, Txt file. |

|

Barcode system |

Camera can read the Barcode automatically(one-dimension or two-dimension) |

|

Operating system |

Windows 7 Professional |

|

Display/Output |

22 inch TFT LCD, OK/NG signal |

|

Camera |

High speed industrial digital camera |

|

System Specifications |

|

|

PCB size |

50×50mm(Min)~510×500mm(Max) |

|

PCB thickness |

0.3 to 5 mm |

|

Clamping system edge learance |

TOP:3.5 mm, Bottom:3.5 mm |

|

PCB weight |

3KG |

|

PCB tolerance |

<5 mm or 2% of PCB diagonal length |

|

PCB height |

Top side: 30 mm, Bottom side: 85 mm |

|

Conveyor system |

Bottom-upfixed, automatic compensation to avoid distortion, auto-load and unload, flat belt, adjust the width automatically |

|

Conveyor height |

890 to 980 mm |

|

Conveyor direction / time |

Left to Right or Right to Left, handling time 5secs |

|

X/Y driver |

Screw and AC servo driver, PCB fixed, Camera in XY, approved with CTQ |

|

Power supply |

AC220V 50/60 Hz <0.5KVA |

|

Compressed air |

0.4~0.8Mpa |

|

Equipment communication |

Smema |

|

Weight |

About 650KG |

|

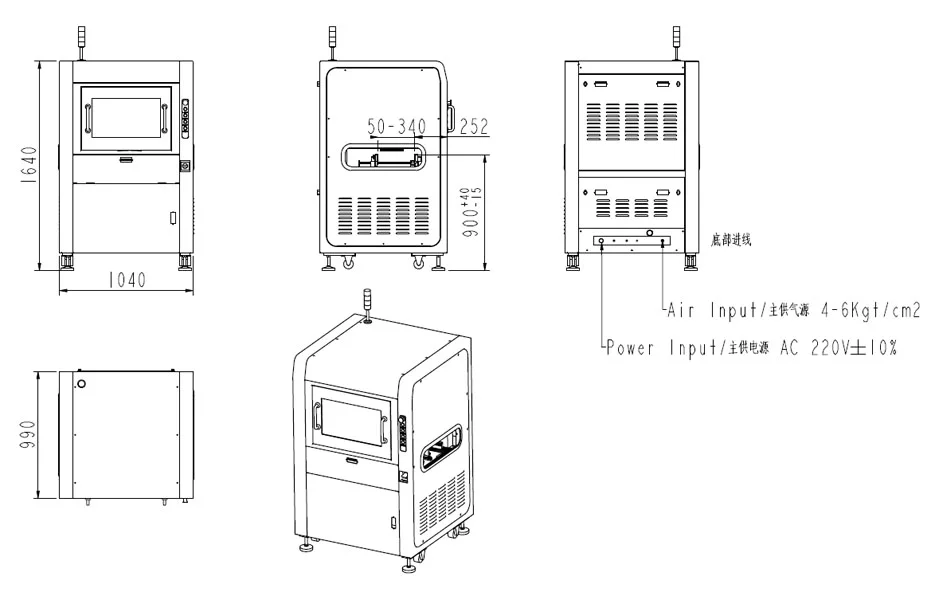

Dimensions |

990×1040×1640mm (L×W×H) excluding the height of signal light |

|

Temperature and humidity |

10~35℃, 35~80% RH(no dew) |

|

Certificate |

According with CE standard |

Inline Automatic Optical AOI was added in Dec 2018

Inline Automatic Optical AOI has been viewed 367 times

9 More Products from Shenzhen rison automatic co.,ltd :