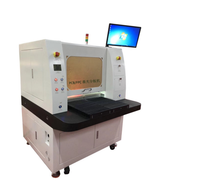

Hot Air Reflow Oven For PCB Soldering Machine SMT Welding Equipment

Company Information:

Name: |

Hot Air Reflow Oven For PCB Soldering Machine SMT Welding Equipment |

Category: |

|

Offered by: |

|

Hot Air Reflow Oven For PCB Soldering Machine SMT Welding Equipment Description:

Up and bottom with 12 heating zones

Introduction:

No.1 The unique advanced long life heating system

1. The heating system adopt the Swedish nickel heater with efficiency and energy-saving. The peak wave length of the

radiation power is 4UM with curved surface reflector to the rising temperature speed, improve the thermal efficiency. And the

special forced-air circulation system make PCB and the component heated uniform and eliminate the "shadow effect"

completely .

2. Using special high temperature resistant protection system in heating preservation system and special iron in furnace .

3. Using imported Taiwan SanYue long axis of high temperature fan motor and W shaped heat pipe, Model design, no noise,

shockless and easy for maintenance .

4. Whole oven are porous aluminum transfer the hot air to guarantee the hot air evenly to the PCB .the whole top oven fixtures

can open completely so that easy to clean the oven inside .

No.2 Smooth and reliable transmission system

1.The transmission system use STK adjustable speed motor imported from Taiwan matched with the 1:150 turbine reducer can

running smooth ,speed range can be arrived at 0-1500mm/min.

2. Independent wheel structure support and match stainless belt to make the running smoothly and the speed precision is up

to ±20 mm/min .

3.Special stainless belt: durable and wear-resistant, not easy to deform and long life.

No.3 Stable and reliable electrical control system

1. It adopts imported thermostat control which owns fuzzy control and PID intelligent precision control system.It can fast

response the changes in external heat and ensure more temperature balanced by PID intelligent operation and automatic

control heating .

2. Using thermocouple imported from Taiwan by each temperature zone, it can fast and sensitive induct the changes in each

temperature zone, transfer and control timely, compensate the temperature balance in each zone.

3 .Special SSR solid state relay matched with dedicated radiator improve the heat efficiency greatly and prolong the lifetime

effectively. No contact output and fuzzy control function by thermostat, can monitoring the changes of outside temperature

and calorific value, controlling the heating device by minimum pulse, ensuring the high precision of the temperature control &

the uniform temperature in internal and the length ,direction, temperature distribution, all of these meet IPC standards .

4. Power is abundant, heat up fast, it’s only need 20 minutes from room temperature to constant temperature.

5 .Failure diagnosis and sound light alarm.

6. Delay shutdown production function, uniform cooling after the shutdown: prevent component deformation.

Specification:

|

Heating System |

Number of heating zones |

UP 6/BOTTOM6 |

|

Length of heating zones |

2500MM |

|

|

Heating mode |

hot air |

|

|

Cooling Mode |

Force air |

|

|

Cooling zones |

Up 1 bottom 1 |

|

|

Conveyor System |

Max. Width of PCB |

350mm |

|

Mesh belt width |

400mm |

|

|

Transmission Direction |

L→R(or R→L) |

|

|

Transmission Net Height |

880±20mm |

|

|

Transmission type |

Mesh and chain |

|

|

Range of rail width |

0-300mm |

|

|

Conveyor speed |

0-1500mm/min |

|

|

Auto/manual Lubrication |

standard |

|

|

Upper hood method |

Manual(option:auto) |

|

|

Fixed rail side |

Front rail fixed(option: rear rail fixed) |

|

|

Components high |

Top 30mm and bottom 25mm |

|

|

Control system |

Power supply |

5line 3phase 380V 50/60Hz |

|

Total power |

24kw |

|

|

Starting power |

18kw |

|

|

Normal power consumption |

4KW |

|

|

Warming time |

About 20 mins |

|

|

Temp. setting range |

Room temperature-300℃ |

|

|

Temp. control method |

PLC & PC |

|

|

Temp. control precision |

±1℃ |

|

|

Temp. deviation on PCB |

±2℃ |

|

|

Data storage |

Process Data and status storage(80GB) |

|

|

Nozzle plate |

Aluminum Alloy Plate |

|

|

Abnormal Alarm |

Abnormal temperature. (extra-high/extra-low temp.) |

|

|

Board dropped alarm |

Tower light: Yellow-warming, Green-normal, Red-abnormal |

|

|

General |

Dimension(L*W*H) |

3600×1100×1490mm |

|

Weight |

900KG |

|

|

Color |

Computer gray |

SMT nitrogent Reflow Oven Control System And Heating System:

1.Siemens PLC+industrial PC with precise controlling unit and stabilezed performance

2.The longer heating zones able to get high prodction offciency and throughput.

Reliable Conveyor System:

1.The rail is dealt with hardened process to make it more stability.

2.The conveyor chain adpoted with single Pin-plate design,Simple and practical.

Hot Air Reflow Oven For PCB Soldering Machine SMT Welding Equipment was added in Nov 2020

Hot Air Reflow Oven For PCB Soldering Machine SMT Welding Equipment has been viewed 227 times

20 More Products from YUSH Electronic Technology Co.,Ltd :

.gif)