SMT Pick and Place assembly line

Company Information:

Name: |

SMT Pick and Place assembly line |

Category: |

|

Offered by: |

|

SMT Pick and Place assembly line Description:

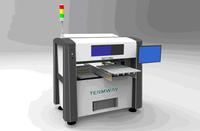

SMT Pick and Place assembly line T8H

Introduction:

1. What is T8H? The homophonic of T8H is Post Hegemony. It is the real” Patch Overlord” in SMT industry in the future.

2. T8H is also the eighth mounting products of TERMWAY with model T8H.

3. The min mounting component is 01005.

4. The max mounting size: 120mm*90mm components (Optional)

5. T8H can mount up to 144 kinds of components.

6. It can pick and place QFP, and the Max PCB size is :48*48mm.

7. Through the modular design, it can easily go upstairs by the elevator without smashing the bricks and windows.

Technical Parameter:

MODEL:T8H

Mounter head:8 heads

The max move range:600*450MM

2.PCB board size:400*350MM

3.Z axis max move range:20mm

4.Typical speed:8000-15000CPH

5.Theoretical Max mount speed:18000CPH

6.Moving System:XY Panasonic servo motor drive + high precision industrial +grating ruler

7.X.Y axis precision:±0.0015mm

8.Repeat Precision:±0.0015mm

9.Component available:Minimum 01005-38*38*8.5mm (48*48 Optional)

10.Programme method:Automatic data input/Video learning/Keyboard input

11.Type of component:MAX 104 pcs GFTA-08S feeder +4 pcs IC

12.Feeder NO.:If place GF type feeder, at the same time it can place 72 pcb feeders GF-8MM GFTA-8S;

If place the DF type feeder, it can work with 144 kinds of components at the same time.

If place CF type feeder ,it can place 80 pcs Feeder at same time.

13.IC tray NO.:The Maximum Number 2pcs (When place 2 pcs IC, the max PCB size is 340*240mm)

14.Operation system:WINDOWS 7

15.Compressed air:80psi(0.5Mpa,gas flue 80L/M

16.Power:220v,50Hz,4kw

17.Weight:860 kg

18.Dimension:1200(L)×1860(W)×1530(H)

Function Introduction

1.With super high precision moving platform technology

which is made by integrated design of Natural granite.

Make sure T8 can get to use for more than10 years

without any effect on moving precision. Meanwhile,

integrated structure ensures a very excellent function in

shock resistance.

2.World-class top speed motion systems: Import

European original magnetic levitation high-precision linear motors and encoders, to minimize mechanical wear and ensure X-axis with high-precision and high-speed performance for long-term use.High-speed performance reach 4M / S.

3.The patented technology of non-stop scanning and

keep taking photos to make high-speed placement

come true. Maximum vision mounting speeds up to

8000-15000CPH and the actual placement

speeds up to 18000CPH

4.Configured with SMART feeder which is the real electric intelligent feeder.The machine can

automatically recognize feeder wherever it comes, make sure the plug and play, save the programming time of picking components. Probe contactless smart feeders can make you more easy to loading and unloading the component.

5.Industry leading vision system: Taking advantage of Germany industrial digital

cameras and high quality lenses, make sure the highquality and high accuracy.

6.Intelligent board transmission system can automatically adjust the width and plywood. Complete

your automated intelligent production.

7.Configurable stick feeder, IC tray and special components bulk trays can meet your all kinds of specific needs.

8. Multi-mount head can be installed seamless, and easy to change according to different requirements. Can be equipped with multi-functional mount head( Model:TH62),High speed mount head(Model:TH61) and high speed multi-functional mount head (Model:TH64)

9.The factories of Termway around the world have set up the quality management system and environmental management system, and achieved international authentication of ISO9001: 2008 and ISO14001: 2008

Beijing Torch Co.,Ltd.

Skype:torchsmt08

Tel:8610-60509015ext862

Mobile:8613241060184

E-mail:s8@tonzh.com.cn

Trade massenger:cn1510945738

Web:www.torchsmt.com

SMT Pick and Place assembly line was added in Mar 2016

SMT Pick and Place assembly line has been viewed 458 times

20 More Products from Beijing Torch Co.,Ltd :