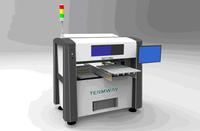

Lead-Free Desktop Reflow Oven with tempereture cure T200N+

Company Information:

Name: |

Lead-Free Desktop Reflow Oven with tempereture cure T200N+ |

Category: |

|

Offered by: |

|

Lead-Free Desktop Reflow Oven with tempereture cure T200N+ Description:

Lead-Free Desktop Reflow Oven with tempereture cure T200N+

Lead-Free Desktop Reflow Oven with tempereture cure T200N+

Product Description

Product Description:

T200N+=nitrogen lead free reflow oven T200N+temperature tester

T200N+ is not only with lead free welding function, but also with temperature measurement function.

1,1.5mm cold-roll steel sheet, impact molding formed for one time

2,TORCH patent of automatic door control technology ? on tray

3,8K mirror 314 stailess steel as furnance

4,Unique hot air cycling system in furnance

5,heating system uses TORCH? heating technology

6,T200N uses the 6th generation of multi-chanel high precision temperature control system

7,LED displayer temp control interface, digital measuring scale shows power output

8,America Omega sensor as temperature testing system, which is the only one in china

9,waste smoke filtration system is used on TORCH reflow oven

10, Appearence, color

11,2 suits of independent protection device on electric control system

12,firstly developed proffesional temperature control software of desktop reflow oven, small oven steps into computer-control age TORCH, as a famous brand Desk Reflow Oven supplier, enjoy good reputation in china and oversea market. it own its own core technoly in SMT industries that other supplier doesn't have

13,Intelligent software system of desktop reflow oven

14,software can satisfy multi operation system and multi language environment of chinese and english

15,remote control function

16,realize RS485 communication and USD interface

17,high temperature protection function

18,configure cool-down system on oven

19,4 layers of industrial package case

20,stailess steel switch on operation panel

21,the first Desktop Nitrogen reflow oven in SMT industry, selling well for 6 years

22,T200N+ is the only one with real-time temperature testing function

T200N+=nitrogen lead free reflow oven T200N with temperature tester

T200N+ is not only with lead free welding function, but also with temperature measurement function.

Adjusting temperature curve constantly in order to get better welding in SMT field. Adjusted temperature is very important which is testing temperature by temperature tester. Temperature tester is used to measure temperature, process improvement and data analysis. In addition it can save data. This machine can meet requirements of ISO9001 system greater.

High reliability; measure actual temperature in real time for pad; draw temperature chart randomly; the format of temperature report is nice; high cost performance.

T200N+ introduce:

T200N+ is manufactured by Torch in 2001, which is the first desk lead free reflow oven.

As an epoch-making product, T200C break instrument controlling market in 2005.

T200N+ is the first nitrogen reflow oven in domestic in 2006. It entered the Texas instrument of United States, University of Texas in United States, Status Pro Corporation in Germany, LOGICOM company in Singapore, Flextronics Technology (Shanghai), Datang Microelectronics Technology Co., Ltd, Tianjin University, Shanghai Jiao Tong University, Beijing University of Technology, Zhenhua semiconductor companies and other well-known research laboratories and factories. and other well-known enterprises and laboratories.

Torch develops and manufactures new products T200N+ according to requirement and need from domestic and foreign market. T200N+ is suitable to small batch products, it is the good choice for electronics enterprises and research institutes, at the same time it is the complementary equipment for large and medium-sized production line.

T200N+ Unique Features:

- With all advance of T200N

- With single channel temperature measurement (multi channels is optical), T200N+ has been the first-class reflow oven. It make up market blank.

- With heater installation technology which is patent in desk reflow oven, the temperature is more uniformity which is less than 10°C, it is the highest standard.

- With air cycle and vent technology which is patent in desk reflow oven, it improve temperature uniformity and air cycle effect.

- With door drive device which is patent in desk reflow oven to make sure worktable stable when PCB is out, and at the same time it can make chips don’t move.

- With save nitrogen technology. When door is open, nitrogen will close automatically, when door is close, nitrogen will open automatically. It can save nitrogen and reduce cost effectively.

- With vent smoke function. It is convenient to emitting exhaust gas.

- With purifying and filtering exhaust gas function

- With automatic door device. When finishing welding, door will open. With airproof technology, it can improve heat preservation effect and save nitrogen.

T200N+ Functions:

1. Computer control:

Operate parameters by computer software can meet different welding requirement.

2. High precision ,multi- functions:

It breaks through the shortages such as the difficulty of meter control program, the difficulty of modify parameter, limited storage of temperature curve. It adopts the software for temperature control, which is produced by Torch itself. The temperature curve can be set intuitively. And a large number of temperature curves can be stored. Analysis and statistics function, printing function.

Batch set 40 segments temperature curve.

3. Real time testing with temperature curve:

Test the temperature curve of soldering at every time. During the process of welding, the actual temperature can be displayed at the same time. It is convenient to adjust and control the lead-free curve. Especially control the heat preservation zone and the melting zone

4. Viewable operation, The real time display of temperature and the real time observation of the welding process. It is the best choice for science research and teaching.

Tested temperature curve

Temperature curve: real temperature curve and history temperature curve can be analyzed, it is convenient to improve.

T200N+ Technology Parameters:

Item Parameter

Temperature control segment:40 segment .The segment can be set in computer according to the actual requirement.

Temperature-zone numbers:Single-zone and multi-segment

Temperature control system:PC control system ,SSR non-contact output.

Temperature accuracy:±2°C

Warm-up time:3min

Temperature range:Room-temperature -360 °C

Heating supply:Infrared ray + Hot air convection

Effective working table area:270mm*220mm (less than A4)

Welding time:3min±1min

Temperature curve:It can be set, adjusted and tested according to the actual requirement .

Cooling system:Transverse flow equal cooling

Rated voltage:AC single-phase ,220V;50Hz

Rated power:3.8KW

Mean power:1.6kw

Weight:45kg

Dimension:820*460*310mm

Beijing Torch Co.,Ltd.

Skype:torchsmt08

Tel:8610-60509015ext862

Mobile:8613241060184

E-mail:s8@tonzh.com.cn

Trade massenger:cn1510945738

Web:www.torchsmt.com

Lead-Free Desktop Reflow Oven with tempereture cure T200N+ was added in Mar 2016

Lead-Free Desktop Reflow Oven with tempereture cure T200N+ has been viewed 591 times

20 More Products from Beijing Torch Co.,Ltd :