Selective Solder Fixtures

Company Information:

Name: |

Selective Solder Fixtures |

Category: |

|

Offered by: |

|

Selective Solder Fixtures Description:

Selective solder fixtures protect bottom side SMT components & eliminate the risk of loosing parts in the solder.

Our unique designs will eliminate skipping and bridging.

- No need to tape areas which reduces operator time and speeds up your line.

- Fixtures available in Titanium, composite material (ROHS compatible) or a combination of both.

- Affixes through-hole components and large parts that must be masked on the bottom side on a fairly heavy printed circuit board.

- Thin wall areas protect SMT components as little as 0.020 in. from through-hole components.

- Millouts for heavy ground-plane areas allow the board to reach temperature and solder properly.

- Combination of composite, which minimizes heat sinking, and titanium, to permit extremely thin walls between SMT parts and through-hole parts – down to 0.01 in. clearance – and still get effective solder.

- A fixture used to very accurately locate (height and width wise) the row of connectors on a circuit board or panel.

|

Selective Solder Fixture with Snap on Cross BarPallet shown has a snap on cross bar with component locator and component hold downs. Cross bar also acts as on inspection template for all through hole parts. |

|

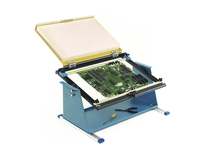

Selective Solder Pallet with Removable CrossbarSelective Solder Pallet with removable crossbar. Spring loaded plungers hold components in place. Threaded inserts are also used to fasten the PCB to the pallet, ensuring flux and solder will not flood the tool. The back of the solder pallet is slotted, chamfered and pocketed to help the solder flow into smaller openings. |

|

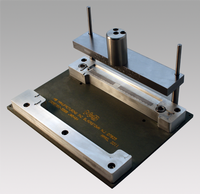

Selective Solder Fixture with Special Component Locating BarMB-Mfg now introduces state of the art component holddowns and support bar mechanisms. The solder pallet features quick simple loading of parts. Holding components to extremely accurate heights of the PCB, while maintaining a 90 degree orientation to the circuit board. |

|

Selective Solder PalletA simple but cost effective method that uses extension spring to hold wires into place for easy soldering. |

|

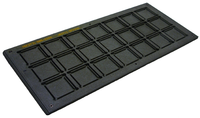

Selective Solder Pallet w Titanium InsertsThis pallet is able to eliminate bridging problems often faced by customers |

|

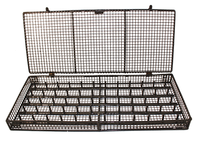

Selective Solder Fixture w Cross BarThis Selective Wave Solder Pallet has a hinged cross bar with spring plungers and pressure pads to prevent parts from lifting or tilting in the wave solder process |

|

Selective Solder Pallet w CrossbarThis selective solder pallet features a removeable crossbar and was made for a high volume PCB to be run on a Seho Wave Solder Machine. |

|

Solid Titanium Selective Solder PalletA pallet able to successfully mask .220" tall bottom side parts that are just .015" away from the thru-hole pads requiring solder. |

Selective Solder Fixtures was added in Feb 2017

Selective Solder Fixtures has been viewed 1202 times

13 More Products from MB Manufacturing :