Henkel Chip-on-Board (COB) Encapsulants

Company Information:

Name: |

Henkel Chip-on-Board (COB) Encapsulants |

Category: |

|

Offered by: |

|

Henkel Chip-on-Board (COB) Encapsulants Description:

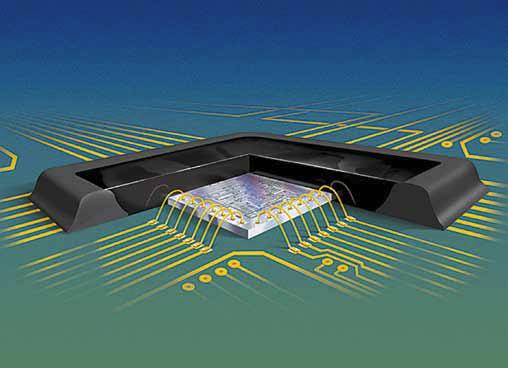

Henkel’s line of Loctite Hysol® and Loctite Eccobond™ encapsulants are primarily used to ensure environmental protection and boost the mechanical strength of wire bonded devices. They are developed to provide protection to wire bonds, leads and aluminum.

Available as either thermal or ultraviolet (UV) cure materials, Henkel encapsulants are designed for the highest reliability using glob top and dam-and-fill application technology:

- Glob top technology requires an encapsulant with a fine-tuned rheology, as the flow capabilities must allow the wires to be covered without the encapsulant flowing beyond the chip.

- Dam and fill technology, where the dam is used to limit the flow of the low viscosity fill material, allowing its use with fine pitch wire leads.

Formulated from epoxy, polyurethane, acrylate (UV curable) and silicone chemistries, these systems have proven reliability for electronic insulation. Henkel encapsulants offer excellent elevated temperature stability and thermal shock resistance, outstanding electrical insulation at both room and elevated temperatures, minimal shrinkage and low stress during cure, as well as excellent chemical resistance. Our encapsulants have been designed to offer high throughput and low-cost assembly processes.

Henkel's Chip-on-Board (COB) Encapsulant Products: |

Cure Type |

Recommended Cure Schedules |

Viscosity |

||

|---|---|---|---|---|---|

DAM |

|||||

|

Damming material is designed as a flow control barrier around areas of bare chip encapsulation. It is a high purity green product with minimal slumping. |

Heat |

30 minutes @ 125°C + 90 minutes @ 165ºC |

1,300,000 |

||

|

Damming material is designed as a flow control barrier around areas of bare chip encapsulation. It has excellent chemical resistance and exceptional thermal stability. |

Heat |

30 minutes @ 125°C + 90 minutes @ 165ºC |

300,000 |

||

|

Developed for encapsulation of wire bonded dies, used for Smartcard IC modules. It is designed for use only with HYSOL UV fill encapsulants, such as 3327 and 3329. |

UV |

100 mW/cm2 @ 365 nm (mercury lamp) |

19,000 to 46,000 |

||

Fill |

|||||

|

Encapsulant designed for protection of bare semiconductor devices. It is high purity, low stress with good moisture resistance. Used on automotive applications, BGA, IC memory cards, chip carriers, hybrid circuits, chip-on-board, multi-chip modules and pin grid arrays. |

Heat |

30 minutes @ 125°C + 90 minutes @ 165ºC |

43,900 |

||

|

Liquid encapsulant features excellent flow properties, allowing it to penetrate fine pitch wires and deep cavities without entrapping voids. A cavity or potting dam is required for flow control. Typical applications are BGA, chip scale packages, PBGA and full arrays on LTCC. |

Heat |

30 minutes @ 125°C + 90 minutes @ 165ºC |

48,000 |

||

|

Developed for encapsulation of wire bonded dies, used for Smartcard IC modules. It is designed for use only with HYSOL UV dam encapsulants, such as HYSOL 3323. |

UV |

100 mW/cm2 @ 365 nm (mercury lamp) |

6,500 to |

||

Glob Tops - Thermal Cure |

|||||

|

Epoxy encapsulant particularly suited for use on transistors and similar semiconductors, can be used for encapsulation of watch ICs. Nonabrasive filler allows for grinding if necessary. |

Heat |

20 minutes at 150°C |

62,000 |

||

|

Medium glob formulation for lower CTE and lower ionic than EO1016. Exceptional viscosity stability at 25°C provides easier control of shot size using conventional time/pressure dispensing equipment. |

Heat |

3 hours @ 140ºC |

50,000 |

||

|

One component epoxy potting system, formulated to protect sensors used in harsh environments, such as automotive applications. |

Heat |

3 hours @ 130ºC or 2 hours @ 140ºC |

40,000 |

||

|

High purity liquid epoxy encapsulant for chip-on-board (COB) plastic substrate and plastic PGA applications. |

Heat |

4 hours @ 150ºC or 1 hour @ 170º C |

220,000 |

||

|

High purity, high flow, low stress glob top semiconductor encapsulant with improved work life. High temperature performance, excellent moisture resistance. |

Heat |

3 hours @ 150ºC |

420,000 |

||

Glob Tops - UV Cure |

|||||

|

A UV encapsulant for IC protection. A grey paste that hardens by UV exposure to a hard translucent coating. |

UV |

100 mW/cm2 @ 315 to 400 nm (mercury lamp) |

2,500 |

||

|

One-component dual cure (UV & moisture) adhesive. Fast cure, withstands exposure to ink, cures in shadowed areas with no stringing. Suited for inkjet applications. |

UV/Moisture |

300 W/in, 5 – 10 ss, 0.5 – 1 Joules (medium pressure mercury vapor lamp) |

4,100 |

||

Henkel Chip-on-Board (COB) Encapsulants was added in Dec 2013

Henkel Chip-on-Board (COB) Encapsulants has been viewed 3125 times

12 More Products from Henkel Electronic Materials :