FCT ASSEMBLY, INC.

With numerous facilities in the United States, we are one of the electronics industry's leading manufacturers of lead-free solder products, superior quality stencils, and precision cut parts.

FCT Assembly was created in April 2004 after the purchase of Fine Line Stencil, Inc. and consists of two basic operations: stencil manufacturing and the manufacture of electronic assembly products such as solder paste, solder flux and solder (both conventional 63/37 and lead free) bar.

The assembly products are manufactured in the Greeley, Colorado plant and the stencils are manufactured in the Colorado Springs, Colorado and Milpitas, California facilities. The stencils can be fabricated by both laser cutting and chemical etch. Additional details of our stencil operation can be obtained by going to our stencil operation web site at www.finelinestencil.com

One of the more exciting changes in the electronic assembly industry is to move towards lead free soldering. A majority of lead free solder paste users in North America have settled on the so-called SAC alloys. This alloy consists of Tin (Sn), Silver (Ag) and Copper (Cu). FCT Assembly provides the solder paste flux vehicles that are compatible with this and other lead free solder paste alloys. In wave soldering, the industry is roughly divided into two lead free solder alloys:

- Sn-Cu alloys such as the Nihon Superior SN100C alloy

- SAC alloy as discussed above.

FCT Assembly is a licensee for the Nihon Superior SN100 lead free solder products for North America and Brazil. A licensing agreement has enabled FCT Assembly to manufacture the Nihon Superior SN100C lead free solder in North America, including Canada, United States, Puerto Rico, and Mexico.

The advantages of SN100C over the SAC alloys are numerous and include:

- Lower raw material cost as a result of no Silver.

- Less drossing with respect to both 63/37 solder bar and SAC bar.

- uch slower copper erosion in the copper plated thru holes and

- Much less attack on the stainless steel solder pots versus the SAC alloys.

FCT ASSEMBLY, INC. Postings

14 products »

BGA Rework Stencils are now available direct to you and may be a major product improvement over what you are may be using now. FCT Assembly BGA Rework Stencils are designed to make your rework faster and cleaner. The materials used, design and pre...

Fine Line Stencil is a technology leading manufacture, committed to delivering the highest quality laser stencils and related products in the industry. Fine Line Stencils highly-polished PrintMaster and Slic-Blade nickel squeegee bl...

Fine Line Stencil is a technology leading manufacture, committed to delivering the highest quality laser stencils in the industry. We use the most advanced laser and material technologies available in the world to meet current and future ind...

By combining our latest wire and alloy technologies with SN100c, FCT Assembly has an advantage over all other suppliers in paste, wire and flux. Product...

FCT Solder has positioned itself as a leader in lead-free solder products. As a licensee of Nihon Superior’s patented technology, we manufacture and sell the leading lead-free alloy, SN100C. FCT Solder is the original licensee of Nihon Su...

FCT Assembly Fluxes are designed to be used with both SN100c and SAC305 alloys. By combining our latest flux tecnologies with SN100c, FCT Assembly has an advantage over all other suppliers in paste, wire and flux. FCT Assembl...

TTC100C - Lead Free Tip Tinner

Tip tinner to aid in cleaning and re-tinning solder iron tips de-wetted by use which can’t be repaired with sponge pads and cored solder wire. Use of TTC100C LEAD FREE Tip Tinner offers the following advantages...

WS159 - Water Soluble Solder Paste

WS159 water washable solder paste is designed to provide humidity tolerance and excellent wetting to meet the requirements for reliable solder joints in PCB Assemblies. WS159 offers high levels of repeatability and consistency even in a wide ra...

AO1000 - Anti-Oxidant Solder Additive

Solder additive to aid in reducing the solder dross buildup in both static and wave soldering pots containing SN100c. AO1000 can reduce solder usage by as much as 50%. FCT Assembly has developed AO1000 Anti-Oxidant S...

FCT Assembly has partnered with Nihon Superior to be able to offer their patented lead free nickel stabilized tin/copper wave solder alloy- SN100C in North America. SN100C was developed to offer a technically superior and more economical option...

14 technical articles »

CHANGING THE RULES OF STENCIL DESIGN

May 22, 2023 | Tony Lentz

Nano-coatings are applied to solder paste stencils with the intent of improving the solder paste printing process. Do they really make a noticeable improvement? The effect of Nano-coatings on solder paste print performance was investigated. Transfer efficiencies were studied across aperture sizes ranging from 0.30 to 0.80 area ratio. Also investigated were the effects of Nano-coatings on transfer efficiencies of tin-lead, lead-free, water soluble, no-clean, and type 3, 4, and 5 solder pastes. Solder paste print performance for each Nano-coating was summarized with respect to all of these variables....

How Does Surface Finish Affect Solder Paste Performance?

Jul 06, 2021 | Tony Lentz

The surface finishes commonly used on printed circuit boards (PCBs) have an effect on solder paste performance in the surface mount process. Some surface finishes are non-planar like hot air solder level (HASL) which can lead to inconsistencies in solder paste printing. Other surface finishes are difficult to wet during reflow like organic solderability preservative (OSP). What is the overall effect of surface finish on solder paste performance? Which solder paste is best for each surface finish? It is the goal of this paper to answer these questions....

Fill the Void V - Mitigation of Voiding for Bottom Terminated Components

Dec 29, 2020 | Tony Lentz, FCT Assembly & Greg Smith, BlueRing Stencils

Voiding in solder joints has been studied extensively, and the effects of many variables compared and contrasted with respect to voiding performance. Solder paste flux, solder powder size, stencil design, circuit board design, via-in-pad design, surface finish, component size, reflow profile, vacuum reflow, nitrogen reflow and other parameters have been varied and voiding quantified for each. The results show some differences in voiding performance with respect to most of these variables but these variables are not independent of each other. Voiding in solder joints is a complex issue that often requires multiple approaches to reduce voiding below required limits. This paper focuses on solutions to voiding for commonly used bottom terminated components (BTCs)....

Size Matters - The Effects of Solder Powder Size on Solder Paste Performance

Oct 27, 2020 | Tony Lentz

Solder powder size is a popular topic in the electronics industry due to the continuing trend of miniaturization of electronics. The question commonly asked is "when should we switch from Type 3 to a smaller solder powder?" Solder powder size is usually chosen based on the printing requirements for the solder paste. It is common practice to use IPC Type 4 or 5 solder powders for stencil designs that include area ratios below the recommended IPC limit of 0.66. The effects of solder powder size on printability of solder paste have been well documented. The size of the solder powder affects the performance of the solder paste in other ways. Shelf life, stencil life, reflow performance, voiding behavior, and reactivity / stability are all affected by solder powder size. Testing was conducted to measure each of these solder paste performance attributes for IPC Type 3, Type 4, Type 5 and Type 6 SAC305 solder powders in both water soluble and no clean solder pastes. The performance data for each size of solder powder in each solder paste flux was quantified and summarized. Guidance for choosing the optimal size of solder powder is given based on the results of this study....

Fill the Void IV: Elimination of Inter-Via Voiding

Oct 10, 2019 | Tony Lentz - FCT Assembly, Greg Smith - BlueRing Stencils

Voids are a plague to our electronics and must be eliminated! Over the last few years we have studied voiding in solder joints and published three technical papers on methods to "Fill the Void." This paper is part four of this series. The focus of this work is to mitigate voids for via in pad circuit board designs.</p><p> Via holes in Quad Flat No-Lead (QFN) thermal pads create voiding issues. Gasses can come out of via holes and rise into the solder joint creating voids. Solder can also flow down into the via holes creating gaps in the solder joint. One method of preventing this is via plugging. Via holes can be plugged, capped, or left open. These via plugging options were compared and contrasted to each other with respect to voiding. Another method of minimizing voiding is through solder paste stencil design. Solder paste can be printed around the via holes with gas escape routes. This prevents gasses from via holes from being trapped in the solder joint. Several stencil designs were tested and voiding performance compared and contrasted.</p><p> In many cases voiding will be reduced only if a combination of mitigation strategies are used. Recommendations for combinations of via hole plugging and stencil design are given. The aim of this paper is to help the reader to "Fill the Void."...

An Investigation Into The Durability Of Stencil Coating Technologies

Mar 13, 2019 | Greg Smith, Tony Lentz

It is well documented that Nano coatings on SMT stencils offer many benefits to those assembling PWBs. With reduced standard deviation and improved transfer efficiency nano coatings can provide, there is also a cost. As PWB assemblers work to justify the return on investment, one key question continues to arise. What is the durability or life of these coatings and what can be done in the print process to maximize the life of the coatings?

This paper addresses durability of the coatings in relation to the number of print cycles and underside wipe cycles applied as well as materials used on the underside wipe process. Different parameters will be applied and data will be collected. The results of this study will be summarized to help those using or considering the use of these nano coatings to improve their print process and suggestions will be given to maximize the life of the coatings....

Fill the Void II: An Investigation into Methods of Reducing Voiding

Oct 03, 2018 | Tony Lentz - FCT Assembly, Patty Chonis, JB Byers - A-Tek Systems

Voids in solder joints plague many electronics manufacturers. Do you have voids in your life? We have good news for you, there are many excellent ways to "Fill the Void." This paper is a continuation of previous work on voiding in which the following variables were studied: water soluble lead-free solder pastes, a variety of stencil designs, and reflow profiles. Quad Flat No-Lead (QFN) component thermal pads were used as the test vehicle. The voiding results were summarized and recommendations were made for reduction of voiding....

Improve SMT Assembly Yields Using Root Cause Analysis in Stencil Design

Jul 18, 2018 | Greg Smith

Reduction of first pass defects in the SMT assembly process minimizes cost, assembly time and improves reliability. These three areas, cost, delivery and reliability determine manufacturing yields and are key in maintaining a successful and profitable assembly process. It is commonly accepted that the solder paste printing process causes the highest percentage of yield challenges in the SMT assembly process. As form factor continues to get smaller, the challenge to obtain 100% yield becomes more difficult.

This paper will identify defects affecting SMT yields in the printing process and discuss their Root Cause. Outer layer copper weight and surface treatment will also be addressed as to their effect on printability. Experiments using leadless and emerging components will be studied and root cause analysis will be presented...

Can Nano-Coatings Really Improve Stencil Performance?

Oct 26, 2017 | Tony Lentz

Nano-coatings have been introduced by various manufacturers, with the promise of addressing some of the challenges relative to solder paste printing. Stated benefits include: Reduced underside cleaning, reduced bridging, improved solder paste release and improvements in yield. With several nano technologies already on the market and more likely to be introduced, how can the performance be quantified? How robust are these coatings? How can an assembler approach the ROI of these coatings? What hidden benefits or negative impacts should be considered?

This paper will present a rigorous method for evaluating the performance and economic benefits of solder paste stencil nano-coatings....

Sep 28, 2017 | Jasbir Bath, Tony Lentz, Greg Smith

These nano-coatings also refine the solder paste brick shape giving improved print definition. These two benefits combine to help the solder paste printing process produce an adequate amount of solder paste in the correct position on the circuit board pads. Today, stencil aperture area ratios from 0.66 down to 0.40 are commonly used and make paste printing a challenge.

This paper presents data on small area ratio printing for component designs including 01005 Imperial (0402 metric) and smaller 03015 metric and 0201 metric chip components and 0.3 mm and 0.4 mm pitch micro BGAs....

176 news releases »

FCT Develops Versatile Water Soluble Flux for Leaded and Lead-Free Soldering

![]() Mar 30, 2016 | FCT Assembly has formulated a unique halogen-free water soluble flux with high activity and neutral pH. FCT's 159HF is a highly versatile solder flux formulated to perform under high temperatures and is compatible with both leaded and lead free alloys. With the low solids content of 159HF, the water soluble flux is applicable in selective; drop-jet spray soldering applications while also being ideal for wave soldering. Because the flux stays active under critical temperatures during pre-heat and wave, 159HF performs exceptionally well in high temperature applications, especially with manufacturers using multilayer boards with lots of heat sink resulting in improved topside fill.

Mar 30, 2016 | FCT Assembly has formulated a unique halogen-free water soluble flux with high activity and neutral pH. FCT's 159HF is a highly versatile solder flux formulated to perform under high temperatures and is compatible with both leaded and lead free alloys. With the low solids content of 159HF, the water soluble flux is applicable in selective; drop-jet spray soldering applications while also being ideal for wave soldering. Because the flux stays active under critical temperatures during pre-heat and wave, 159HF performs exceptionally well in high temperature applications, especially with manufacturers using multilayer boards with lots of heat sink resulting in improved topside fill.

FCT Develops Versatile Water Soluble Flux for Leaded and Lead-Free Soldering

![]() Mar 29, 2016 | FCT Assembly (www.fctassembly.com), a leader in the development and manufacturing of high performance solders and advanced fluxes; has formulated a unique halogen-free water soluble flux with high activity and neutral pH. FCT’s 159HF is a highly versatile solder flux formulated to perform under high temperatures and is compatible with both leaded and lead free alloys.

Mar 29, 2016 | FCT Assembly (www.fctassembly.com), a leader in the development and manufacturing of high performance solders and advanced fluxes; has formulated a unique halogen-free water soluble flux with high activity and neutral pH. FCT’s 159HF is a highly versatile solder flux formulated to perform under high temperatures and is compatible with both leaded and lead free alloys.

FCT to Showcase Advanced Printing Technologies at APEX 2016

![]() Feb 25, 2016 | FCT Assembly (www.fctassembly.com), well-known in the electronics assembly industry for its Fine Line Stencil and FCT Solder divisions, will highlight its broad portfolio of printing products at IPC APEX 2016 (www.ipcapexexpo.org), as well as take part in multiple technical conference programs. From booth # 1139 over March 15 - 17, the FCT exhibit will play host to the company’s various technologies including innovative step/relief stencil capabilities, NanoSlic Gold coated stencil and newly formulated, pre-released water soluble paste, WS890.

Feb 25, 2016 | FCT Assembly (www.fctassembly.com), well-known in the electronics assembly industry for its Fine Line Stencil and FCT Solder divisions, will highlight its broad portfolio of printing products at IPC APEX 2016 (www.ipcapexexpo.org), as well as take part in multiple technical conference programs. From booth # 1139 over March 15 - 17, the FCT exhibit will play host to the company’s various technologies including innovative step/relief stencil capabilities, NanoSlic Gold coated stencil and newly formulated, pre-released water soluble paste, WS890.

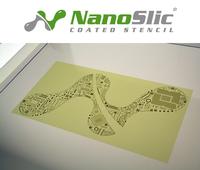

Licensed Stencil Manufacturers Feature Florida CirTech’s NanoSlic Coating

![]() Feb 24, 2016 | Introduced to the electronics market in 2014, NanoSlic is a proprietary thermoset polymer coating that renders metals, glass and polymers hydrophobic and oleophobic for improved protection and performance. FCT has developed not only the breakthrough chemistry, but also the equipment and application process that provide a turnkey stencil coating solution, NanoSlic Gold. Though used in multiple markets (www.nanoslic.com) for various safeguarding purposes, for electronics assembly applications, NanoSlic-coated stencils dramatically improve printing performance.

Feb 24, 2016 | Introduced to the electronics market in 2014, NanoSlic is a proprietary thermoset polymer coating that renders metals, glass and polymers hydrophobic and oleophobic for improved protection and performance. FCT has developed not only the breakthrough chemistry, but also the equipment and application process that provide a turnkey stencil coating solution, NanoSlic Gold. Though used in multiple markets (www.nanoslic.com) for various safeguarding purposes, for electronics assembly applications, NanoSlic-coated stencils dramatically improve printing performance.

Fine Line Stencil Upgrades Step Stencil Technology

![]() Dec 04, 2015 | December 3, 2015 – Continuing to invest in the most advanced stencil production technologies, FCT Assembly’s Fine Line Stencil division today announced that it has added a next-generation micro-milling system to its operation to enable production of highly-accurate step -- or multi-level -- stencils.

Dec 04, 2015 | December 3, 2015 – Continuing to invest in the most advanced stencil production technologies, FCT Assembly’s Fine Line Stencil division today announced that it has added a next-generation micro-milling system to its operation to enable production of highly-accurate step -- or multi-level -- stencils.

FCT Assembly’s NanoSlic® Stencil Coating Recognized for its Electronics Assembly Innovation

![]() Nov 17, 2015 | November 17, 2015 -- At last week’s Productronica event held in Munich, Germany, FCT Assembly was honored with a Global Technology Award for its new, VOC-free stencil coating, NanoSlic® (www.nanoslic.com). This award win comes on the heels of several successes for NanoSlic, including recent expansion of the company’s licensing network and increased use of the coating technology among global electronics manufacturing firms.

Nov 17, 2015 | November 17, 2015 -- At last week’s Productronica event held in Munich, Germany, FCT Assembly was honored with a Global Technology Award for its new, VOC-free stencil coating, NanoSlic® (www.nanoslic.com). This award win comes on the heels of several successes for NanoSlic, including recent expansion of the company’s licensing network and increased use of the coating technology among global electronics manufacturing firms.

FCT Assembly to Showcase Comprehensive Product Line and have Major Presence at SMTA International

![]() Sep 01, 2015 | FCT Assembly (www.fctassembly.com), well-known in the electronics assembly industry for its Fine Line Stencil and FCT Solder divisions, will highlight its broad portfolio of products at SMTA International 2015 (www.smta.org/smtai/), as well as take part in the conference program and live process demonstrations on the show floor.

Sep 01, 2015 | FCT Assembly (www.fctassembly.com), well-known in the electronics assembly industry for its Fine Line Stencil and FCT Solder divisions, will highlight its broad portfolio of products at SMTA International 2015 (www.smta.org/smtai/), as well as take part in the conference program and live process demonstrations on the show floor.

A-Laser Helps Cardica Produce Next-Generation Medical Devices

![]() Aug 04, 2015 | Cardica, a designer and manufacturer of proprietary stapling and automated anastomotic devices for cardiac and laparoscopic surgical procedures, has partnered with precision laser-cutting and engineering firm, A-Laser, to expand and refine its line of next-generation medical devices.

Aug 04, 2015 | Cardica, a designer and manufacturer of proprietary stapling and automated anastomotic devices for cardiac and laparoscopic surgical procedures, has partnered with precision laser-cutting and engineering firm, A-Laser, to expand and refine its line of next-generation medical devices.

A-Laser Expands Facility, Announces Appointment of New Operations Manager

![]() Jun 08, 2015 | A-Laser, an FCT Companies business, today announced that it has doubled the size of its precision laser and marking facility to accommodate growing demand for its services. Simultaneously, the company has appointed optics, photonics and global inventory specialist, Fred Schumacher, to the position of Operations Manager. Together, these moves will position A-Laser for continued growth and success.

Jun 08, 2015 | A-Laser, an FCT Companies business, today announced that it has doubled the size of its precision laser and marking facility to accommodate growing demand for its services. Simultaneously, the company has appointed optics, photonics and global inventory specialist, Fred Schumacher, to the position of Operations Manager. Together, these moves will position A-Laser for continued growth and success.

FCT and Fine-Line Stencil Expand Market Presence with New Facility in Guadalajara, Mexico

![]() Jun 08, 2015 | FCT Companies, a leading chemistry, electronic stencil and specialty manufacturing business, announces the official opening of its new state-of-the-art facility in Guadalajara, Mexico. While FCT has long had a significant presence in Mexico through sales, service and distribution, the company’s Fine-Line Stencil operation in Guadalajara marks its first manufacturing site in the region and is a noteworthy addition to the broad FCT offering.

Jun 08, 2015 | FCT Companies, a leading chemistry, electronic stencil and specialty manufacturing business, announces the official opening of its new state-of-the-art facility in Guadalajara, Mexico. While FCT has long had a significant presence in Mexico through sales, service and distribution, the company’s Fine-Line Stencil operation in Guadalajara marks its first manufacturing site in the region and is a noteworthy addition to the broad FCT offering.