KYZEN Corporation

A leading supplier of precision cleaning chemistries to the worldwide electronics, metal finishing, medical, semiconductor, and optical industries.

Founded in Nashville, Tennessee, KYZEN is the worldwide leader in the precision cleaning industry. Kyzen provides award winning cleaning chemistries for electronics and advanced packaging applications. We offer a broad range of process solutions ranging from sprayable aqueous cleaning formulations to engineered vapor degreasing solvents. Kyzen also has a fully equipped applications lab staffed with experts to help with customer process development. All of our products are environmentally friendly and effective in virtually all cleaning systems available today. Our goal is to provide our customers with integrated cleaning SOLUTIONS!

KYZEN’s Nashville, Tennessee USA Operation is unique with extensive Research and Developmental, Applications Testing, manufacturing and Global Headquarters functions. These best in the world facilities are complemented by our Applications and Engineering Laboratory in Manchester, New Hampshire, USA. These laboratories are fully equipped to support product development, analytical services, process development and customer process support challenges.

KYZEN Corporation Postings

32 products »

AQUANOX® A4727 - Enhanced Aqueous Assembly Cleaner

AQUANOX A4727 is an award-winning electronics assembly cleaning solution that provides exceptional results when cleaning printed circuit boards and advanced packaging assemblies. A4727 has been lab and field-tested in spray-in-air processes...

AQUANOX® A4241 - Solution for PCB & Stencil Cleaning

AQUANOX® A4241 is an aqueous cleaning solution designed with revolutionary inhibition technology to be effective on the toughest soils while protecting even the most sensitive parts from etch or darkening. AQUANOX® A4241can b...

AQUANOX® A4625 - Aqueous In-Line Cleaning Solution

AQUANOX® A4625 is a versatile aqueous cleaning chemistry designed to clean the latest lead-free residues while providing brilliant mirrored solder finishes. Easy to use, AQUANOX® A4625 is environmentall...

AQUANOX® A4625B - Aqueous Batch Cleaning Solution

AQUANOX® A4625B is an innovative aqueous chemistry designed for optimum effectiveness in batch washers. This easy to use product will remove all types of electronic flux residues including the latest lead free. AQUANOX® A4625B...

AQUANOX® A4633 - High Alkaline Aqueous Electronics Cleaning Solution

Concentrated Aqueous Electronics Cleaner AQUANOX® A4633 was designed to clean flux residues from electronic assemblies in high and medium pressure batch and in-line spray washers having short wash zones. The ingredients used in A46...

AQUANOX® A4638 Advanced Packaging Cleaning Chemistry

Advanced Packaging Cleaning Chemistry AQUANOX® A4638 is an engineered electronic assembly and advanced packaging cleaning agent designed to remove flux residue from flip chip and low clearance components. AQUANOX&r...

AQUANOX® A4639 - Electronic Assembly Aqueous Solution

AQUANOX® A4639 is an engineered aqueous cleaning fluid that is effective on a wide range of soils at low operating temperatures and concentrations. AQUANOX® A4639 provides exceptional cleaning results and protection of metallic surfaces wi...

AQUANOX® A4651US - Low pH Ultrasonic Immersion Cleaner

AQUANOX® A4651US is a low pH aqueous cleaning solution designed exclusively for use in ultrasonic immersion cleaning systems. AQUANOX® A4651US will provide brilliant solder joints with no sump side additives and cleans exceptio...

AQUANOX® A4703 - Neutral pH Aqueous Cleaner

AQUANOX® A4703 is an aqueous cleaning solution designed with a pH neutral formulation combined with Kyzen's revolutionary inhibition technology providing superior material compatibility. A4703 is effective at concentrations as low as three...

AQUANOX® A4708 - pH Neutral Electronic Assembly Cleaning Chemistry

AQUANOX® A4708 is a neutral range pH chemistry designed to rapidly clean under densely populated low-gap PWB assemblies. AQUANOX® A4708 is effective on all flux types including no-clean and water soluble residues. AQUANOX®...

11 technical articles »

May 22, 2023 | Chrys Shea, Mike Bixenman, T.C. Loy, Debbie Carboni, Brook Sandy-Smith, Greg Wade, Ray Whittier, Joe Perault, Eric Hanson

Over the past several years, much research has been performed and published on the benefits of stencil nano-coatings and solvent under wipes. The process improvements are evident and well-documented in terms of higher print and end-of-line yields, in improved print volume repeatability, in extended under wipe intervals, and in photographs of the stencil's PCB-seating surface under both white and UV light. But quantifying the benefits using automated Solder Paste Inspection (SPI) methods has been elusive at best. SPI results using these process enhancements typically reveal slightly lower paste transfer efficiencies and less variation in print volumes to indicate crisper print definition. However, the improvements in volume data do not fully account for the overall improvements noted elsewhere in both research and in production....

The Relationship Between Cleanliness and Reliability/Durability

Apr 17, 2023 | Debbie Carboni

Outline/Agenda * Introduction of Ionics and ROSE * Evolution in technology * Rev H in the IPC-J-STD-001 * Real World Case Study * Conclusions...

Stencil Cleaning - A Practical Approach To Improving Yields And Maximizing Your Throughput

Nov 10, 2021 | Debbie Carboni

Main Points * Technologies for the job * More than a flat piece of Stainless * Compatibility * Solubility in stencil cleaning * Influencing factors * Best Practices to reduce misprints and increase yields...

Nov 04, 2020 | Mike Bixenman, DBA [Kyzen Corporation] Mark McMeen, [STI Corporation] Bruno Tolla, Ph.D. [Kester Corporation]

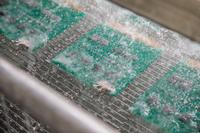

Residues present on circuit boards can cause leakage currents if not controlled and monitored. How "Clean is Clean" is neither easy nor cheap to determine. Most OEMs use analytical methods to assess the risk of harmful residues. The levels that can be associated with clean or dirty are typically determined based on the exposed environment where the part will be deployed. What is acceptably clean for one segment of the industry may be unacceptable for more demanding segments. As circuit assemblies increase in density, understanding cleanliness data becomes more challenging. The risk of premature failure or improper function is typically site specific. The problem is that most do not know how to measure or define cleanliness nor can they recognize process problems related to residues. A new site specific method has been designed to run performance qualifications on boards built with specific soldering materials, reflow settings and cleaning methods. High impedance measurements are performed on break off coupons designed with components geometries used to build the assembly. The test method provides a gauge of potential contamination sources coming from the assembly process that can contribute to electrochemical migration....

Aug 14, 2019 | Mike Bixenman - KYZEN Corporation, Vladimir Sitko, Pavel Hub - PBT Works

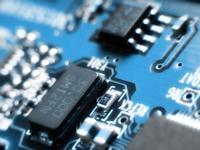

Cleanliness is a product of design, including component density, standoff height and the cleaning equipment’s ability to deliver the cleaning agent to the source of residue. The presence of manufacturing process soil, such as flux residue, incompletely activated flux, incompletely cured solder masks, debris from handling and processing fixtures, and incomplete removal of cleaning fluids can hinder the functional lifetime of the product. Contaminates trapped under a component are more problematic to failure. Advanced test methods are needed to obtain "objective evidence" for removing flux residues under leadless components.</p><p>Cleaning process performance is a function of cleaning capacity and defined cleanliness. Cleaning performance can be influenced by the PCB design, cleaning material, cleaning machine, reflow conditions and a wide range of process parameters.</p><p>This research project is designed to study visual flux residues trapped under the bottom termination of leadless components. This paper will research a non-destructive visual method that can be used to study the cleanability of solder pastes, cleaning material effectiveness for the soil, cleaning machine effectiveness and process parameters needed to render a clean part....

Electrochemical Methods to Measure the Corrosion Potential of Flux Residues

Jul 27, 2017 | Mike Bixenman, DBA, David Lober, Anna Ailworth - Kyzen Corporation, Bruno Tolla, Ph.D., Jennifer Allen, Denis Jean, Kyle Loomis - Kester Corporation

Reliability Expectations of Highly Dense Electronic Assemblies is commonly validated using Ion Chromatography and Surface Insulation Resistance. Surface Insulation Resistance tests resistance drops on both cleaned and non-cleaned circuit assemblies. It is well documented in the literature that SIR detects ionic residue and the potential of this residue to cause leakage currents in the presence of humidity and bias. Residues under leadless components are hard to inspect for and to ensure flux residue is totally removed. The question many assemblers consider is the risk of residues that may still be present under the body of components....

Duo-Solvent Cleaning Process Development for Removing Flux Residue from Class 3 Hardware

Jul 28, 2016 | Mike Bixenman, DBA - Kyzen Corporation | Ryan Hulse, PHD - Honeywell International | Joe McChesney - CSD Automation

Packaging trends enable disruptive technologies. The miniaturization of components reduces the distance between conductive paths. Cleanliness of electronic hardware based on the service exposure of electrical equipment and controls can improve the reliability and cost effectiveness of the entire system. Problems resulting from leakage currents and electrochemical migration lead to unintended power disruption and intermittent performance problems due to corrosion issues.

Solvent cleaning has a long history of use for cleaning electronic hardware. Limitations with solvent based cleaning agents due to environmental effects and the ability to clean new flux designs commonly used to join miniaturized components has limited the use of solvent cleaning processes for cleaning electronic hardware. To address these limitations, new solvent cleaning agents and processes have been designed to clean highly dense electronic hardware.

The research study will evaluate the cleaning and electrical performance using the IPC B-52 Test Vehicle. Lead Free noclean solder paste will be used to join the components to the test vehicle. Ion Chromatography and SIR values will be reported....

Combination of Spray and Soak Improves Cleaning under Bottom Terminations

Oct 23, 2014 | Dr. Mike Bixenman; Kyzen Corporation, Julie Fields; Technical Devices Company, Eric Camden; Foresite.

The functional reliability of electronic circuits determines the overall reliability of the product in which the final products are used. Market forces including more functionality in smaller components, no-clean lead-free solder technologies, competitive forces and automated assembly create process challenges. Cleanliness under the bottom terminations must be maintained in harsh environments. Residues under components can attract moisture and lead to leakage currents and the potential for electrochemical migration (...)

The purpose of this research study is to evaluate innovative spray and soak methods for removing low residue flux residues and thoroughly rinsing under Bottom Termination and Leadless Components...

Stencil Printing Yield Improvements

Jun 05, 2014 | Dr. Mike Bixenman, Debbie Carboni, Jason Chan

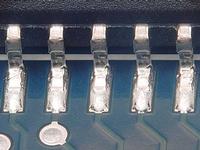

Stencil printing capability is becoming more important as the range of component sizes assembled on a single board increases. Coupled with increased component density, solder paste sticking to the aperture sidewalls and bottom of the stencil can cause insufficient solder paste deposits and solder bridging. Yield improvement requires increased focus on stencil technology, printer capability, solder paste functionality and understencil cleaning.

(...) The purpose of this research is to study the wipe sequence, wipe frequency and wipe solvent(s) and how these factors interact to provide solder paste printing yield improvement....

Compatibility of Cleaning Agents With Nano-Coated Stencils

Mar 12, 2013 | David Lober and Mike Bixenman, D.B.A.

High density and miniaturized circuit assemblies challenge the solder paste printing process. The use of small components such as 0201, 01005 and μBGA devices require good paste release to prevent solder paste bridging and misalignment. When placing these miniaturized components, taller paste deposits are often required. To improve solder paste deposition, a nano-coating is applied to laser cut stencils to improve transfer efficiency. One concern is the compatibility of the nano-coating with cleaning agents used in understencil wipe and stencil cleaning. The purpose of this research is to test the chemical compatibility of common cleaning agents used in understencil wipe and stencil cleaning processes.Compatibility of Cleaning Agents With Nano-Coated Stencils...

602 news releases »

Three members of KYZEN Clean Team to give technical presentations at IPC APEX 2024

![]() Apr 03, 2024 | KYZEN announced today that three members of the Clean Team will give technical presentations as part of KYZEN's participation at the 2024 IPC APEX EXPO, scheduled to take place April 9-11, 2024.

Apr 03, 2024 | KYZEN announced today that three members of the Clean Team will give technical presentations as part of KYZEN's participation at the 2024 IPC APEX EXPO, scheduled to take place April 9-11, 2024.

KYZEN Showcases Chemistry and Control Innovation with the New ANALYST2 at APEX

![]() Mar 11, 2024 | KYZEN is pleased to announce its participation in the upcoming 2024 IPC APEX EXPO, scheduled to be held April 9-11, 2024 at the Anaheim Convention Center in California. As an exhibitor in Booth 4237, KYZEN will spotlight the powerful combination of Chemistry and Control, with a focus on its cutting-edge products, AQUANOX A4618 and the new KYZEN ANALYST2.

Mar 11, 2024 | KYZEN is pleased to announce its participation in the upcoming 2024 IPC APEX EXPO, scheduled to be held April 9-11, 2024 at the Anaheim Convention Center in California. As an exhibitor in Booth 4237, KYZEN will spotlight the powerful combination of Chemistry and Control, with a focus on its cutting-edge products, AQUANOX A4618 and the new KYZEN ANALYST2.

KYZEN Celebrates Another Year of Cleaning Innovation – Wins 17th NPI Award

![]() Mar 11, 2024 | KYZEN is proud to announce that it has been awarded the prestigious 2024 CIRCUITS ASSEMBLY NPI Award in the category of Cleaning Materials for its groundbreaking AQUANOX® A4618 Aqueous In-Line Cleaning Solution. KYZEN continues to develop new chemistries each year to stay ahead of the ever-changing cleaning needs of the industry.

Mar 11, 2024 | KYZEN is proud to announce that it has been awarded the prestigious 2024 CIRCUITS ASSEMBLY NPI Award in the category of Cleaning Materials for its groundbreaking AQUANOX® A4618 Aqueous In-Line Cleaning Solution. KYZEN continues to develop new chemistries each year to stay ahead of the ever-changing cleaning needs of the industry.

KYZEN's AQUANOX A4618 and Process Control System at SMTA Dallas Expo and Tech Forum

![]() Mar 04, 2024 | KYZEN will exhibit at the SMTA Dallas Expo and Tech Forum, scheduled to take place Tuesday, March 19, 2024 at Plano Event Center in Plano, TX. The KYZEN Clean Team will provide information about AQUANOX A4618 and the KYZEN Process Control System (PCS) during the event.

Mar 04, 2024 | KYZEN will exhibit at the SMTA Dallas Expo and Tech Forum, scheduled to take place Tuesday, March 19, 2024 at Plano Event Center in Plano, TX. The KYZEN Clean Team will provide information about AQUANOX A4618 and the KYZEN Process Control System (PCS) during the event.

Stencil and PCB Cleaning Solutions from KYZEN at SMTA Monterrey

![]() Mar 04, 2024 | KYZEN, the global leader in innovative environmentally friendly cleaning chemistries, will exhibit at the SMTA Monterrey Expo & Tech Forum, scheduled to take place Thursday, March 14, 2024 at the Cintermex Convention Center, Hall 2A in Monterrey, Nuevo León. KYZEN will showcase the new aqueous chemistry AQUANOX A4618 in addition to highlighting stencil cleaning chemistries KYZEN E5631J and CYBERSOLV C8882.

Mar 04, 2024 | KYZEN, the global leader in innovative environmentally friendly cleaning chemistries, will exhibit at the SMTA Monterrey Expo & Tech Forum, scheduled to take place Thursday, March 14, 2024 at the Cintermex Convention Center, Hall 2A in Monterrey, Nuevo León. KYZEN will showcase the new aqueous chemistry AQUANOX A4618 in addition to highlighting stencil cleaning chemistries KYZEN E5631J and CYBERSOLV C8882.

KYZEN to debut new online video series "Ask Dr. Adam" on March 6

![]() Feb 26, 2024 | KYZEN is thrilled to announce the premier of a new online video series "Ask Dr. Adam." The show is hosted by KYZEN Director of Science Adam Klett, Ph.D., and the first episode of the series will be available to viewers on Wednesday, March 6, 2024, with new episodes releasing weekly thereafter.

Feb 26, 2024 | KYZEN is thrilled to announce the premier of a new online video series "Ask Dr. Adam." The show is hosted by KYZEN Director of Science Adam Klett, Ph.D., and the first episode of the series will be available to viewers on Wednesday, March 6, 2024, with new episodes releasing weekly thereafter.

KYZEN to Spotlight Stencil Cleaning Specialties at SMTA Capital Expo and Tech Forum

![]() Feb 19, 2024 | KYZEN will exhibit at the SMTA Capital Expo and Tech Forum, scheduled to take place Thursday, March 7, 2024, at Sweeney Barn in Manassas, Virginia. The KYZEN Clean Team will provide expert insight on improving stencil cleaning processes and information about the KYZEN E5631 and E5631J solutions.

Feb 19, 2024 | KYZEN will exhibit at the SMTA Capital Expo and Tech Forum, scheduled to take place Thursday, March 7, 2024, at Sweeney Barn in Manassas, Virginia. The KYZEN Clean Team will provide expert insight on improving stencil cleaning processes and information about the KYZEN E5631 and E5631J solutions.

KYZEN to Spotlight Two Solvents for Medical Device Cleaning at MD&M West

![]() Jan 02, 2024 | KYZEN will exhibit at MD&M West 2024, scheduled to take place Feb. 6-8, 2024, at the Anaheim Convention Center in Anaheim, CA. The KYZEN clean team will discuss METALNOX M6093 and M6386, and the effective applications of both products in cleaning medical devices at Booth 3085.

Jan 02, 2024 | KYZEN will exhibit at MD&M West 2024, scheduled to take place Feb. 6-8, 2024, at the Anaheim Convention Center in Anaheim, CA. The KYZEN clean team will discuss METALNOX M6093 and M6386, and the effective applications of both products in cleaning medical devices at Booth 3085.

KYZEN Receives 2023 GLOBAL Technology Award for New Aqueous In-Line Cleaning Solution

![]() Nov 20, 2023 | KYZEN is proud to announce its recent recognition with a 2023 GLOBAL Technology Award in the category of Cleaning Materials. The award was presented during an award ceremony that took place at productronica in Munich on Nov. 14, 2023, celebrating KYZEN's groundbreaking contribution to the industry with its revolutionary AQUANOX® A4618 Aqueous In-Line Cleaning Solution.

Nov 20, 2023 | KYZEN is proud to announce its recent recognition with a 2023 GLOBAL Technology Award in the category of Cleaning Materials. The award was presented during an award ceremony that took place at productronica in Munich on Nov. 14, 2023, celebrating KYZEN's groundbreaking contribution to the industry with its revolutionary AQUANOX® A4618 Aqueous In-Line Cleaning Solution.

![]() Oct 30, 2023 | KYZEN has been honored with the prestigious Mexico Technology Award in the category of Cleaning Materials for its revolutionary AQUANOX® A4618 Aqueous In-Line Cleaning Solution. The award ceremony took place on Wednesday, October 25, 2023, during the SMTA Guadalajara event held in Mexico.

Oct 30, 2023 | KYZEN has been honored with the prestigious Mexico Technology Award in the category of Cleaning Materials for its revolutionary AQUANOX® A4618 Aqueous In-Line Cleaning Solution. The award ceremony took place on Wednesday, October 25, 2023, during the SMTA Guadalajara event held in Mexico.

.jpg)

.gif)