Low Speed Automatic SMT Production Line Cheap Solutions

Company Information:

Name: |

Low Speed Automatic SMT Production Line Cheap Solutions |

Category: |

|

Offered by: |

|

Low Speed Automatic SMT Production Line Cheap Solutions Description:

Low Speed Automatic SMT Production Line Cheap Solutions

- Cheap SMT Assembly line

- Lower price PCB Assembly line

- low speed SMT production line

- second hand PCB production line

- Product description: Low Speed Automatic SMT Production Line Cheap Solutions

-

INQUIRY

Low Speed Automatic SMT Production Line Cheap Solutions

Machine Details:

Low Cost SMT Assembly Line- All equipments can be second hand one, Total Solutions lower than 25000USD. Welcome to contact US and got a final solutions.

1. PCB loader

Micro computer controlled component ensures machine’s stable and reliable running.

Optional Fuji buttons interface or touch panel interface, convenient man-machine interaction.

Multiple sound and light alarming functions

Use standard magazines, good compatibility, load with 3 magazines at one time.

Lifting distance adjustable according to PCB, 4 kinds of distance(10mm, 20mm, 30mm and 40mm)

Loader configured with inner push board component, save the cost of buying PCB moving machine independently.

Automatic counting function make it easy of production statistic

Optional SMEMA port for communication between machines.

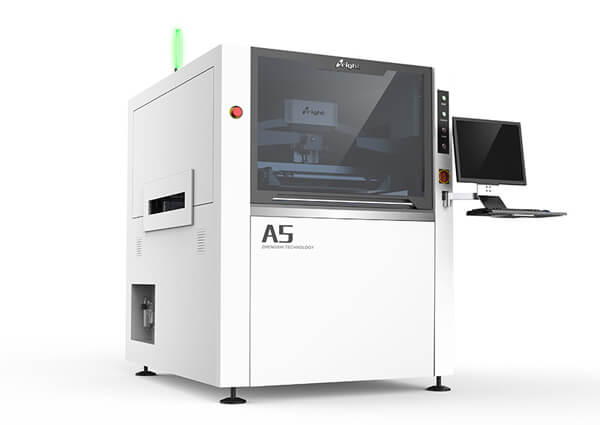

2. Automatic smt stencil printer A5

A Seriel smt stencil printer is high accuracy and high stability of the fully automatic printingmachine vision,We followed in SMT industry is the development trend of production of a new generation of fully automatic printing machine with the international leading technology synchronous vision, visual processing of high resolution, high precision of thetransmission system, suspension adaptive scraper.

Specification :

A Series High Precision Automatic solder paste printer designed for high precision

steel mesh printing or stencil printing in SMT industry.

Printing PCB size:50mm x 50mm ~1200mm x 800mm;

PCB thickness: 0.4mm ~ 14mm

FPC thickness: ≦0.6mm (Excluding jig)

Applicable pitches of Components

SMT Components such as resistors, capacitors, inductors, diode and triode: 0201, 0402, 0603, 0805, 1206 and other specifications;

IC: support SOP, TSOP, TSSOP, QFN packaging, min. pitch 0.3mm; support BGA, CSP packaging,

min. ball 0.2mm;

Applicable PCB Types

Applicable to PCB types of mobile phone, communication, LCD TV, STB, family cinema, vehicle electronics,

medical power equipment, aerospace and aviation, besides general electronics products.

3. Second hand Chip Mounter JUKI KE750.

JUKI mid-speed placement machine 750

automatic / manual

automatic

Patch speed

8000 (grain / hour)

PCB Dimensions:

L: 50.0 mm (min) -330.0 mm (max), W: 30.0 mm (min) -250.0 mm (max).

PCB thickness:

0.40mm (min) -4mm (max)

Technical Parameters:

Component placement range:

0402-48mm * 48mm (chip, sot, sop, melf, QFP, connector, sop, plcc)

Component height:

0.3mm-10.5mm.

Pin spacing (Min):

0.4mm.

Component Dimensions:

0.5mm * 1.0mm (Min), 23.5mm * 23.5mm (Max).

Nozzle Model:

10X, 20X.

Mounting accuracy:

± 0.1mm (LA), ± 0.04mm (LAIC)

Mounting Speed (Max):

11,250 components / hour

4. Second Hand Reflow Oven.

No.1 The unique advanced long life heating system

1.The heating system adopt the Swedish nickel heater with efficiency and energy-saving. The peak wave length of the radiation power is 4UM with curved surface reflector increasing temperature ramp up speed, improve the thermal efficiency. The special forced-air circulation system make PCB and the component heated uniform and eliminate the "shadow effect" completely.

2. Using special high temperature barrier structure for heat preservation and special iron in Heating passage.

3. Using imported Taiwan SanYue long shaft high temperature blower motor and W shaped heat duct, no noise & vibration, convenient for maintenance.

4. Heating zones with porous aluminum plate directing the hot air to guarantee the heat evenly distributed to the PCB. Hood can open completely so that convenient for cleanup.

No.2 Smooth and reliable transmission system

1. The conveyor system use STK adjustable speed motor imported from Taiwan matched with the 1:150 turbine reducer can running smooth, speed varies in 0-1000mm/min.

2. Independent roller structure support and match stainless steel mesh belt to make the running smoothly and the speed precision is up to ±20 mm/min.

3.Special stainless steel mesh belt: durable and wear-resistant, long lifetime.

No.3 Stable and reliable electrical control system

1. It adopts imported thermostat control which owns fuzzy logic and PID close loop system. It can fast response to temperature changes and ensure temperature compensation by PID intelligent operation.

2. Using thermocouple imported from Taiwan to each temperature zone, it can fast and sensitive response the changes in each temperature zone, feedback and control timely, compensate the temperature stability in each zone.

3. Special SSR solid state relay matched with dedicated heat dissipating block improve the heat efficiency greatly and prolong the lifetime effectively. Non-contact output and fuzzy control function by thermostat, can monitor the changes of environmental temperature, controlling the heating device by minimum pulse, ensuring the high precision of the temperature control & the uniform internal temperature. The length ,direction, temperature distribution, all these meet with IPC standards .

4. Heat energy is abundant, heat up fast, it’s only need 20 minutes from room temperature to set-point temperature.

5. Failure diagnosis, visual & audio alarm.

6. Delay shutdown production function, uniform cooling after the shutdown: prevent hardwares thermal damaged.

Keywords:

SMT Assembly line, PCB Assembly line, LED Production line, Automatic SMT Assembly line, Semi Automatic SMT Assembly line, JUKI SMT Assembly Line, Samsung SMT Assembly Line, Hanwha SMT Assembly Line, Panasonic SMT Assembly Line, FUJI SMT Assembly Line, Yamaha SMT Assembly Line.

QISMT Co.,ltd provide a full SMT assembly line solutions, including SMT Reflow Oven, Wave Soldering Machine, Pick and Place Machine, SMT Stencil Printer, SMT AOI SPI Machine, SMT Peripheral Equipment, SMT Production line, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: wechat whatsapp:+8617748683433, Skype: qismteric, Email: sales@qismt.com

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is English manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / skype/ phone /trademanager online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

5)Why choose us ?

A. Gold supplier on Alibaba !

B. Trade assurance to US$54,000 !

C. Best price & Best shipping & Best service !

CATEGORIES

CONTACT US

Contact: Eric

Phone: +86 17748683433

Tel: 0755-85225569

Add: No.94, Guangtian Road, Songgang Street, Bao`an District Shenzhen

When SMT matters to your business, partner with QISMT. Where innovation takes form. Mr Eric. sales@qismt.com Wechat whatsapp:+86177 48683433 skype:qismteric

Low Speed Automatic SMT Production Line Cheap Solutions was added in Oct 2021

Low Speed Automatic SMT Production Line Cheap Solutions has been viewed 43 times

20 More Products from qismt electronic co.,ltd :