AI Technology, Inc. (AIT), a pioneer in the technology of self-supporting die-attach film (DAF) adhesive has just increased its manufacturing capacity to more than 10 million square feet of its 10 micron thick ESP7660 series of insulating DAF for memory stacked chip applications and its 20 micron thick ESP8660 series of conductive DAF for power devices.

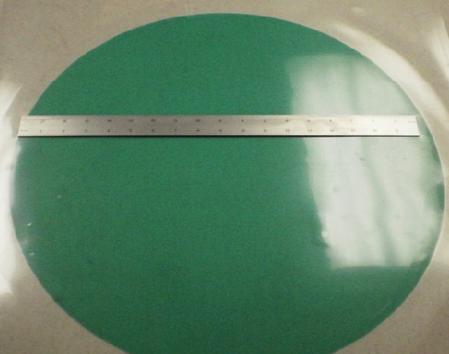

Since the 1990’s, AIT has been known for manufacturing high performance die-attach film adhesives for stacked chips of over 20 layers with military reliability. Now, AIT’s engineering team has successfully implemented an advanced automated line of DAF manufacturing and advanced PLC control for even better control of thickness and higher capacity. This adoption of a higher capacity line under a clean room environment represents AIT’s commitment to provide the best products for its semi-conductor customers domestically as well as those located in Asia. AIT’s new manufacturing line for DAF is able to make DAF for the newer 450mm wafer technology that will become more important in coming years.

AIT’s DAF is used for various Commercial and Military applications such as in medical, RF and MW devices, as well as in stacked chip assemblies for memory devices. For many applications very thin DAF is required to meet stacked chip heights in dense packages. For example, in RF and MW devices the thickness of the DAF is critical to reach higher frequency signals required in many current applications. In some cases very thin DAF is required to increase the thermal conductivity between the heat sink and the device. However, if the film adhesive becomes too thin, voids are formed which produces poor wet out and decreased bond strength and electrical performance. AIT’s DAF is not only thin but is formulated to be VOID-FREE so that bond strength, thermal conductivity and electrical performance perform as well or better than they do in much thicker films.

Since pioneering the use of flexible epoxy technology for microelectronic packaging in 1985, AI Technology, Inc. (AIT) has been one of the leading forces in development and patented applications of advanced materials and adhesive solutions for electronic interconnection and packaging. AI Technology, Inc. (AIT) offers some of the most reliable adhesives and underfills for die bonding for the largest dies, stack-chip packaging with dicing die-attach film (DDAF), flip-chip bonding and underfilling and high temperature die bonding for single and multiple-chip modules for applications beyond 230°C. The company continues to provide the best adhesive solution for component and substrate bonding for both military and commercial applications.

AIT’s thermal interface material solutions, including our patented phase-change thermal pads, thermal greases and gels and thermal adhesives have set many bench marks of performance and reliability for power semiconductors, modules, computers and communication electronics.

For an application analysis: http://www.aitechnology.com/analysis/

Media Contact: Amy Grossman, (609) 799-9388, agrossman@aitechnoloy.com