Though traditional ball attach tacky fluxes have been used for POP production, poor POP yields have made it increasingly evident that these formulations are not ideal for the industry’s newest stacked package configurations. Henkel, therefore, has designed Multicore TFN700B to address the unique needs of POP product builds.

One of the most common issues with device stacking is ensuring that there is ample flux coverage to facilitate robust solder joint formation. Though this is partly attributable to process conditions – specifically, flux transfer consistency – Henkel’s Multicore TFN700B development process has revealed that flux formulation methodology is also critical. Typically, tacky fluxes used in assembly processes are non-Newtonian, meaning that they shear thin when used in application and their success relies heavily on establishing near-perfect processing methods. Because process parameters and equipment sets vary from manufacturer to manufacturer, non-Newtonian fluxes have resulted in low POP yields. Henkel’s Multicore TFN700B, however, is a Newtonian-based system and, therefore, eliminates the shearing conditions associated with traditional tacky flux formulations, thus delivering flux transfer consistency and compensating for varied process conditions.

“Drawing on Henkel’s depth of materials science expertise, we were able to engineer a novel flux to enable successful, high-yield POP processes,” says Dr. Mark Currie, Henkel Global Product Manager for Semiconductor Soldering. “By taking a fresh approach to flux formulation methodologies, Henkel’s Multicore TFN700B was conceived and will now play a large role in advancing POP technology – and the Newtonian formulation is only part of the story!”

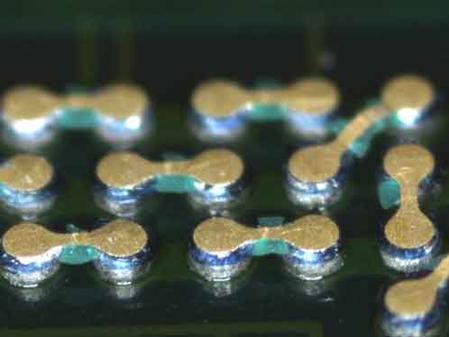

Consistency in coverage is, of course, at the foundation of Multicore TFN700B, but POP device assemblers also want to have visual confirmation that required flux deposition volumes have been achieved. The ability for the pick and place system to visually verify flux volume and distribution has long been desired but, until now, no materials supplier has been able to deliver. Driven by this challenge, Henkel scientists engineered an inventive, patented blue color system that enables optical recognition of flux by pick and place systems. This unique technology is built into Multicore TFN700B and allows visual verification of flux volume before placement of the top component of the POP package. This capability improves throughput and enables outstanding end-of- the-line yield.

Among its other notable benefits, Multicore TFN700B is no-clean, halide-free and is suitable for various deposition methods including doctor blading and dip transfer for POP builds. The material has a consistent tack force over time, outstanding drop test reliability and is ROLO classified, or non-hydroscopic and non-corrosive.

For more information on Multicore TFN700B, call Henkel and 949-789-2500 or log onto http://www.henkel.com/electronics.

About Henkel

Henkel has been committed to making people's lives easier, better and more beautiful for more than 130 years. A Fortune Global 500 and Germany's most admired company according to a recent Fortune survey, Henkel offers strong brands and technologies in three areas of competence: Home Care, Personal Care and Adhesive Technologies. Each day, more than 52,000 employees in

125 countries are dedicated to fulfilling Henkel's claim "A Brand like a Friend.” In fiscal 2008, Henkel generated sales of 14,131 million euros and adjusted operating profit of 1,460 million euros.