YAMAHA YSP10 SMT Stencil Printer

Company Information:

Name: |

YAMAHA YSP10 SMT Stencil Printer |

Category: |

|

Offered by: |

|

YAMAHA YSP10 SMT Stencil Printer Description:

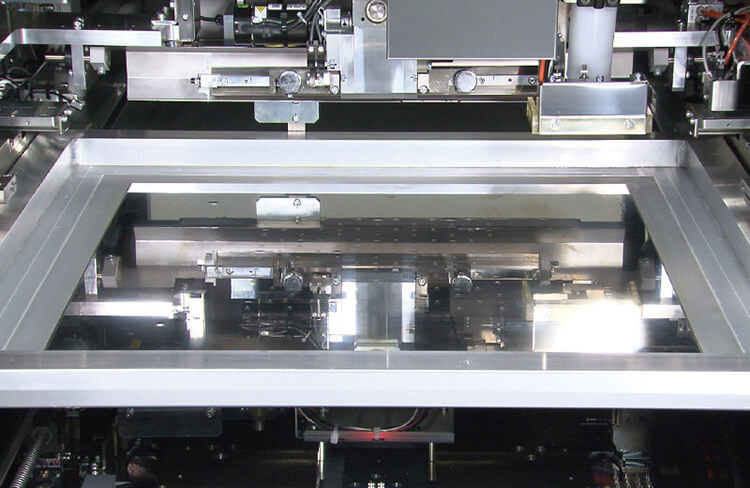

YAMAHA YSP10 SMT Stencil Printer

YAMAHA YSP10 SMT Stencil Printer

PCB Max Size:650X510mm

Positioning repeatability (6σ) : +/- 0.01mm

size:L1,640 x W1,840 x H1,525mm (Standard)

Weight:1700Kg

YAMAHA YSP10 SMT Stencil Printer

YAMAHA YSP10 SMT Stencil Printer achieved high productivity by totally redesigning the drive system to optimize the movement layout and cut the board transfer time to attain a cycle time including stencil cleaning of 12 seconds at the world's fastest level (optimal in-house conditions. Normal print time is 10 seconds.) reaching a speed 20% faster than conventional operation.

Supports fully autonomous stencil exchange

Automatic stencil replacement(Option)

The function presets the stencil needed for the next production task while the printer is operating and automatically makes setups-changeovers. Space-saving design with small footprint sets and recovers used stencils all in one batch at the machine rear. This slashes the time needed for stencil replacement since workers can do stencil presetting in advance whenever they have time available without having to stop the printer. The squeegee head is now equipped with a new solder receiver plate to prevent solder from falling onto the stencil during replacement.

Automatic solder transfer(Option)

During stencil replacement, this function automatically scoops up solder paste remaining on the used stencil and swiftly transfers it to the new stencil now in place. Solder paste transfer takes place during auto stencil replacement while maintaining the rolling diameter which eliminates lost time and human error in setups and changeovers.

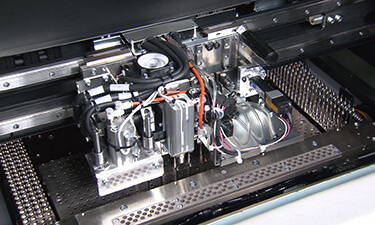

Automatic push-up pin exchange function(Option)

The function automatically replaces the push-up pins which support the PCB from below. Two gripper heads do high-speed replacements that not only slash setup/changeover times but also reduce human error. Even the large PCB such as 420x420mm can be supported by maximum of 200 pins with a margin. Pin layout can be set using mounter data and images captured by AOI, simplifying data creation.

Delivers both high quality & super-accurate printing!

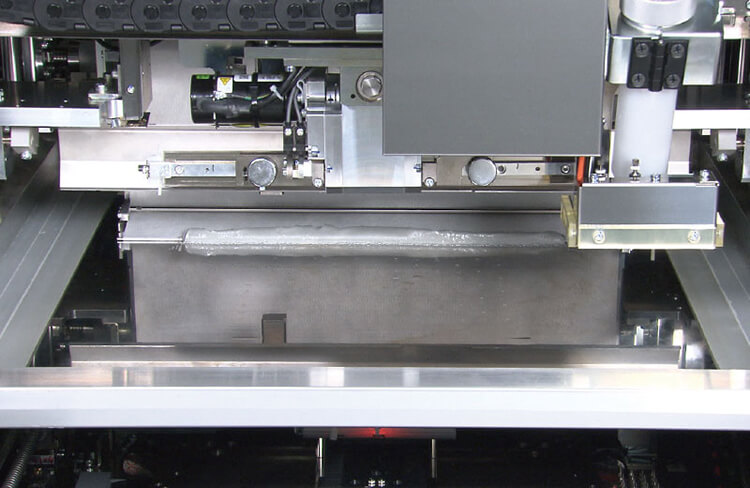

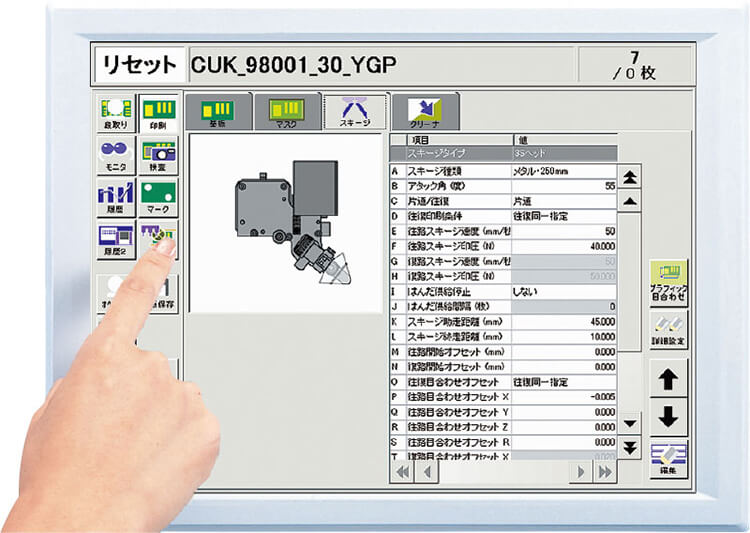

YAMAHA’s original 3S head[3S:Swing Single Squeegee]

Program change squeegee attack angle and speed to an ideal setting to provide optimal printing conditions that match the solder being used.

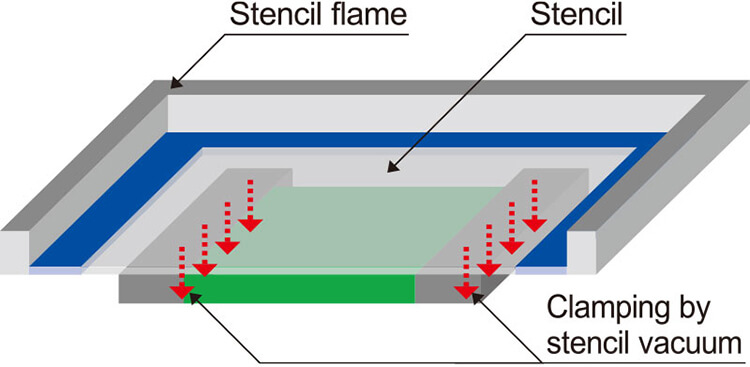

Stencil vacuum

A stencil vacuum mechanism delivers consistent high accuracy printing with no effects from stencil droop. Also drastically cuts the setup time since no offset entry is needed during back and forth printing movement.

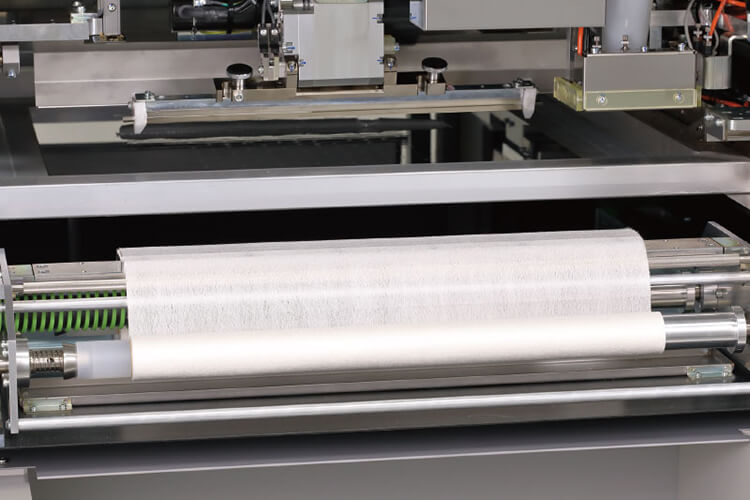

Auto cleaning system

High efficiency cleaning system as standard equipment. New cleaner head ensures a huge reduction in cleaning cloth consumption.

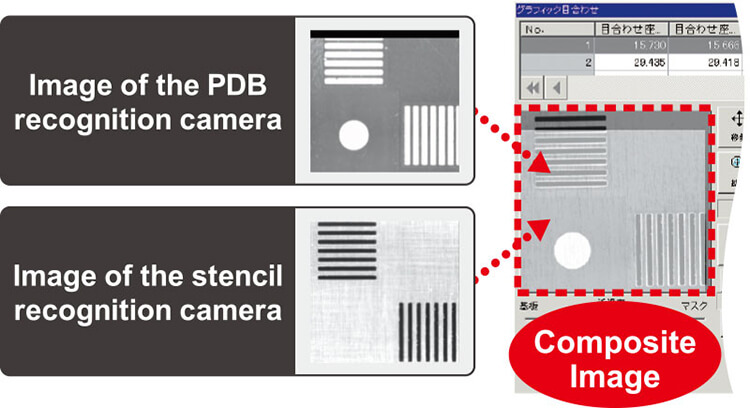

Composite image alignment function

By images from two cameras are combined in layer, thereby operation of the PCB to printing stencil relative positioning can be performed simply and accurately.

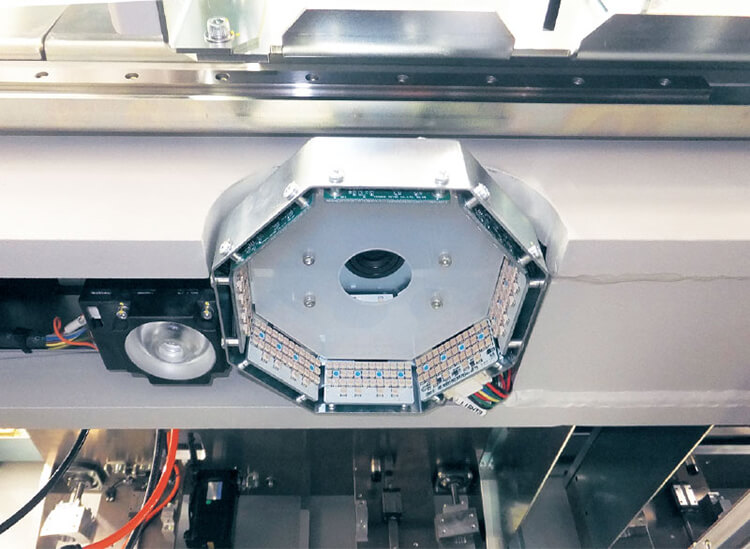

Print inspection function(Option)

Supports full-on pro-level inspections with a dedicated camera. Feedback from inspection results allow over-printing and stencil cleaning.

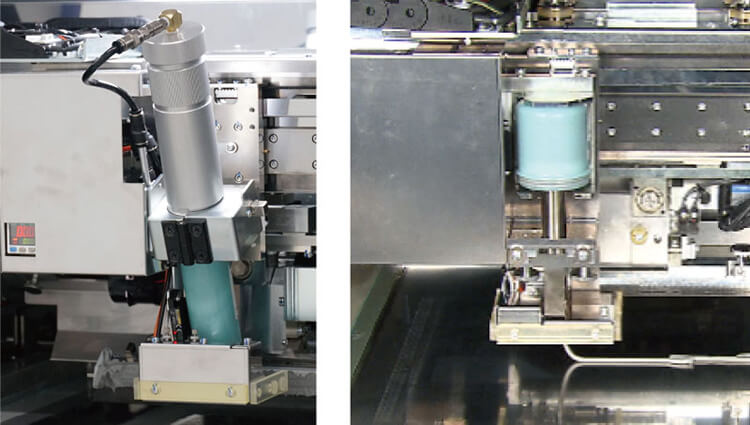

PSC System (Option)[PSC:Print Stability Control]

Stabilizes the rolling diameter of solder paste that affects print quality. A newly developed 12oz syringe type PSC system realizes non-stop production for a long time.

Supports extra-large boards & large-size stencils

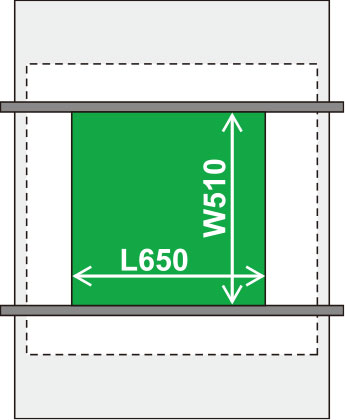

Supports extra-large boards

Expands large-size board support range from L510 x W460mm on up to L510 x W510mm boards. Also extends support range to include large-size mother boards including multiple smaller boards, large-size liquid crystal panel lighting boards and large-size industrial boards. Coverage of extra-large L610 x W510mm boards is available as an option.

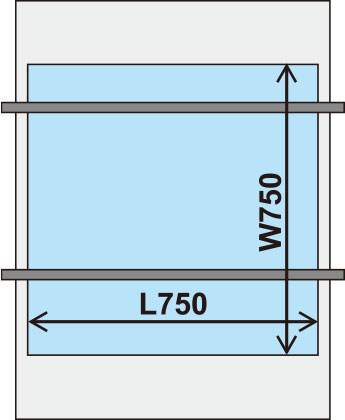

Large stencil sizes

Supports L or large stencil sizes to maximum dimensions of L750 x W750mm. Instantly handles up to 5 stencil types sizes with just one touch.

Full range of options

Touch panel

|

YAMAHA YRP10 SMT Stencil Printer |

|

|

Applicable PCB |

L510 x W510mm to L50 x W50mm (option : L650 x W510mm) |

|

Dual lane : L420 x W330mm to L50 x W50mm |

|

|

Printing heads |

3S head (3S : Swing Single Squeegee) |

|

Printing accuracy |

Positioning repeatability (6σ) : +/- 0.01mm |

|

Cycle time |

10sec Note : Not including cleaning (under optimum condition) |

|

Core cycle time (Not include printing) |

6sec |

|

Applicable stencil size |

L750 x W750mm, L736 x W736mm (29′) |

|

Power supply |

Single-phase AC 200 to 230V +/-20V |

|

Air supply source |

0.4MPa or more |

|

External dimension |

L1,640 x W1,840 x H1,525mm (Standard) |

|

Weight |

Approx. 1,700kg |

Keywords:

SMT Stencil printer, Automatic SMT solder paste printer, SMT printing machine, SMT PCB printer, GKG stencil printer, 600mm Solder paste printer, 1200mm solder paste printer, Max Solder paste printer, Solder Paste Jet Dispenser, SMT Jet Printer, Panasonic SMT Stencil Printer, JUKI Solder Paste Printer, DEK Stencil printer, SMT Stencil printer Manufacturer, YAMAHA Stencil printer, FUJI Stencil printer,

Professional SMT machine supplier. If you have any needs, please contact us.

Hanwha Pick and Place Machine:XM520, HM520, HM510, Excen PRO, Decan S2, Decan S1, SM485P, SM482 Plus, SM481 Plus, SM471 Plus

Yamaha Pick and Place Machine: YRM20DL, YRM20, YSM40R, YSM20R, YSM20WR, YSM10, F8S, YS12F, YG12, YG100RA, YS24F

JUKI Pick and Place Machine: LX-8, RX-8, RX-7R, RX-7, RS-1R, RS-1, RS-1XL,JM-20, JM-100, FX-3RA, KE-3010A, KE-3020VA

Panasonic Pick and Place Machine: NPM-GH, NPM-DX, NPM-D3A, NPM-D3, NPM-WX/WXS, NPM-TT2, AM100, VM101, VM102

FUJI Pick and Place Machine: AIMEX III, AIMEX R, NXT III, NXTR-S, NXTR-A, NXT M6 III, NXT M6 Ⅱ, NXT M3 III, NXT M3 Ⅱ,

Siemens Chip Mounter: SIPLACE XS Series, SIPLACE SX Series, Siplace DX Series, SIPLACE TX Series,

SMT Stencil Printer: GKG, DEK, JUKI, FUJI, Yamaha, Panasonic, SMT Glue Dispenser, Semi-Auto stencil printer,

SMT Reflow oven: 6 Zones, 8 Zones, 10 Zones, 12 Zones, Heller, Ersa, JT

Insert Plug-in machine: Hanwha, JUKI, Yamaha, Panasonic, Offline Insert Plug-in machine, Vertical Plug-in machine, Heterotypic Plug-in machine

Wave Soldering Machine: Dual Rail Wave Soldering Machine, lead free Wave Soldering Machine, Nitrogen Wave Soldering Machine, Selective Soldering Machine, Ersa Wave Soldering Machine, JT Wave Soldering Machine

SMT Inspection machine: Saki SPI/AOI, Koh Young SPI/AOI, JUKI SPI/AOI, Omron SPI/AOI, Yamaha SPI/AOI, Flying Probe Testing Machine, X-Ray Inspection Machine, In-Circuit Tester,

SMT Peripheral Equipment: PCB Loader, PCB Unloader, PCB Conveyor, PCB Transfer Shuttle Conveyor, Auto BGA Rework Station, PCB loader Buffer Stocker, PCB Cleaning Machine, SMT Nozzle Cleaning Machine, PCB Separator Depanelizer Machine, Automatic inline Labelling Machine, SMT Screen Developing and Stripping Machine, SMT Ionic Contamination Tester, SMT Camera Module Cleaning Machine, Reflow Oven Cooler Cleaning Machine, SMT Fixture Cleaning Machine, PCB Stencil Cleaning Machine, PCB Laser Marking Machine, PCB Circuit Repair Machine, Thermal Profiler for reflow oven,

SMT Spare Parts: JUKI Feeder, Yamaha Feeder, Panasonic Feeder, Sansung/Hanwha Feeder, FUJI Feeder, Seimens Feeder, Mydata Mycronic Feeder, Feeder Storage Cart, Tray Feeder, Feeder Calibration jigs, JUKI Nozzle, Yamaha Nozzle, Panasonic Nozzle, Samsung/Hanwha Nozzle, FUJI Nozzle, Universal GSM Nozzle, Siemens SIPLACE ASM Nozzle, Mydata Nozzle, JUKI Spare parts, Yamaha Spare parts, Panasonic Spare parts, Samsung/Hanwha Spare parts, Siemens Spare Parts, FUJI Spare Parts, Mycronic Spare Parts,

SMT WORKSHOP LINE: SMT LOADER+ SMT printer+ SMT SPI+ SMT chip mounter+ SMT reflow oven

Add: No. 4, Yangyong Industrial Zone, Shapu Community, Songgang Street, Baoan District, Shenzhen China Tel: +86 -137 14564591 Skype:sales@effsmt.com E-mail:sales@effsmt.com

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is English manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / phone /Wechat online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

YAMAHA YSP10 SMT Stencil Printer was added in Jan 2024

YAMAHA YSP10 SMT Stencil Printer has been viewed 9 times

20 More Products from Efficient Technology Co., Ltd :