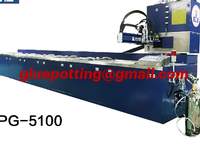

sandwich panel Two-component polyurethane (PU) glue laminating machine

Company Information:

Name: |

sandwich panel Two-component polyurethane (PU) glue laminating machine |

Category: |

|

Offered by: |

|

sandwich panel Two-component polyurethane (PU) glue laminating machine Description:

Two-component polyurethane (PU) glue laminating machine

The two-component polyurethane (PU) glue spraying machine is mainly used to evenly and quickly spray the two-component polyurethane A and B glue mixture on the bonding surface of larger-format boards, such as RV compartment panels, refrigerated compartment panels, fire doors, etc. Insulation boards, rock wool fireproof boards, aluminum honeycomb panels, etc. The equipment adopts PLC programming control and intelligent touch screen operation, making the equipment operation simple and easy to learn. The two storage tanks store the A and B components of the rubber separately; according to the performance and process requirements of the rubber, the rubber in the tank can be heated (lower the viscosity to make it more fluid), Stirring (preventing precipitation, ensuring uniform material temperature), vacuuming (vacuum degassing, vacuum preservation of raw materials) and other pre-treatments. A suitable metering pump is matched according to the performance of the rubber material and the process flow requirements. The metering system uses a stepper motor to drive the imported precision metering pump to achieve accurate metering and continuous and stable supply of glue A and B. Static mixer and special customized spray head ensure uniform mixing and spray coating.

Automatic AB potting machine is composed of Five Systems:

- Vacuum material-feeding system or diaphragm pump feeding system

- High precision pump metering system

- Dynamic/Static mixing system

- Three-axis motion system

- Programming control system.

AB-component materials flows into the pump through the feeding system (AB tanks) separately by the self-suction force of the metering pump.

Semi automatic gue dispensing machine

- Vacuum material-feeding system

- High precision pump metering system

- Dynamic/Static mixing system

- Manual dispensing by glue gun or pedal .

AB-component materials flows into the pump through the feeding system (AB tanks) separately by the self-suction force of the metering pump.

Features :

Strong versatility / Multiple configuration / High production capacity / High precision

- Auto feeding : take use of vacuum pressure to feed materials into A&B tank separately.

- Tank Stirring : A and B tank configure with stirring motors and blades to prevent material sediment in the tank bottom .

- Heating : Tank , pipe , pumps are optional with heaters to assure the whole system can be heating from room temperature to 90°C adjustable.

- Vacuum : A &B tank vacuum for degas the bubble inside material .

- Dynamic mixing : Configuring dynamic motor and mixer to mix A and B fluids evenly.

Advantages:

1,Accurated metering and even mixing helps to avoid the waste of material.

2,Dispensing volume and positioning keep machine work consistent and fast.

3,Good universality

4,Easy to program and operate.

5,Tally function, non-standard mode, primer mode, level alert, filter mode, liquid display device, preventing back-flow device and other functional device.

- Applications:

Potting&Encapsulation &Casting: electronics componnets , PCB board, Capacitor, power supply, transformer, ignition coil, reverse sensor, circuit board, filter products ,underwater parts, electronic ballast ,aviation parts, aerospace parts....

Dispensing&Dosing : LED strip , led lamp , led bulb , aluminum,led screen , display module ,medical parts,medical liquid filling ....

Bonding&doming : LCD screen ,LOCA bonding,ABS plastic,different types of stickers , badge , keychains , souvenirs ,arts , photo frame , and other arts graphics....

Transformer , capacitance , power module , regulating plate ,protection module , generator , pressure package , soli relay ,fault indicator , Sensors , junction box , clutch , wave filter , water meter , boattery cover , rectifier and so on ...

Suitable Material

1K and 2-component polyurethanes, epoxies, acrylics, silicones, temperature, humidity and UV curing materials.

Two component potting materials , 2-part compound materials, AB part compound materials , 2K silicones ,2K epoxies resin, Bi-component PU, Ployerster, Polyurethane, UV materials and so on .

Machine description and working principle

Compound materials A & B are kept in two tanks separately. There are two sets of metering pumps inside the machine for metering A and B resin by setting ratio, draining out material individually from tank A & B. Liquid A & B mix with each other in the mixer pipe and dispensed out according to the programmable data.

|

Sara Dong |

|

|

|

Email: gluepotting@gmail.com

Experts for 2k epoxy/silicone/polyurethane potting machine, meter mix dispenser

sandwich panel Two-component polyurethane (PU) glue laminating machine was added in Nov 2023

sandwich panel Two-component polyurethane (PU) glue laminating machine has been viewed 24 times

20 More Products from Guangzhou Daheng Automation Equipment Co.,LTD :