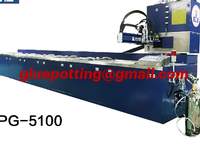

China 2 part resin potting machine for automotive Parking sensor potting machinme

Company Information:

Name: |

China 2 part resin potting machine for automotive Parking sensor potting machinme |

Category: |

|

Offered by: |

|

China 2 part resin potting machine for automotive Parking sensor potting machinme Description:

Whatsapp 0086 134 2516 4065

Vacuum booster pressure sensor potting machine, DPS differential pressure sensor potting machine, Hall effect position sensor potting machine, Temperature sensor potting machine, Tire pressure sensor potting machine

Sensors are potted in order to permanently protect electronic components from external influences such as heat, moisture, vibration, or chemical influences. our dispensing pumps ensure high-precision, high-quality potting processes in the most diverse applications. In combination with the appropriate one or two-component potting materials for the respective application, perfect, customer-specific solutions are created. Depending on the application, the dispensing pumps master a variety of challenges.

system accurately meters, mixes and dispenses two-component medium to low-viscosity materials for potting, gasketing,sealing, encapsulation and syringe filling. For variable ratio dispensing, the system handles ratios from 1:1 to 10:1.

system accurately meters, mixes and dispenses two-component medium to low-viscosity materials for potting, gasketing,sealing, encapsulation and syringe filling. For variable ratio dispensing, the system handles ratios from 1:1 to 10:1.

The system is composed of material tank, metering pump, metering motor, material pipe, two component valve, motor for dynamic stirring, mixing tube and 3 axis robotic arms. Two kinds of glue are separated before they mix in mixing tube, so the glue will not cure in devices. Glue valve is with vacuum function to keep thin fluid from dripping. Other optional functions include:

Tank stirring function;

Tank defoaming function;

Thermostat heating function on Tank, pipe, and valve;

Features:

1. Automatic metering and mixing, touch screen PLC control system, English operation interface allow easy to set parameters;

2. Big LCD screen displays various processing data;

3. Easy programming of dots, stripes, arcs, compound arcs and patterns on different planes;

4. Gluing speed and timing can be set;

5. CAD file can be imported and turned to be dispensing patterns, and downloaded via USB; (optional function)

6. Mixing ratio 1:1-1:10 and gluing volume can be set and adjusted as per actual need. Dynamic mixing ensure two component glue to be mixed to a fully homogeneous consistency;

7. Metering, mixing and gluing simultaneously;

8. Two tanks keep A glue and B glue separately;

9. Liquid level sensor, alarm function;

10. Tank stirring and vacuum defoaming function optional;

11. Auto cleaning; The cleaning mode can be manually or automatically, manual mode just remove the mixing tube then soak into cleaning agent, after 10 min take out and clean with compressed air, Automatic mode only need to operate the cleaning switch on touch screen within 1 minute to complete;

12. Glue tank/metering pump/glue pipe heating function (optional);

13. Vacuum control keeps thin fluids from dripping;

14. Unique control system which will not influenced by air pressure factor, ensures optimal dispensing performance;

15. XYZ axis can be programmed to dispense glue along desired patterns.

III.Specification:

| Model No: | PGB-700 |

| Mixing Ratio | 100:100-10:100(1:1-1:10) Adjustable |

| Metering precision | ±1% |

| Outflow speed | 1g/sec-15g/sec |

| Mixing precision | ±1% |

| Mixing mode | Dynamic mixing /Static mixing |

| Glue Viscosity | Lower than 20000 CPS(mPa·s) |

| Control mode | PLC + Touch Screen |

| Control system | Independent R&D |

| Measuring mode |

Stepping motor/High-precision, wear-resistant, long-life Gear pump |

| Working voltage | AC 220V 50Hz/60Hz |

| Power requirement | 3.55KW |

| Air pressure requirement | 4.5-8KG |

| Machine Dimension | 1500(L)*1200(W)*1500(H)mm |

| Weight | approx 260 KG |

| Work environment | Humidity: 20%~98%RH; Temperature: 0~+40°c |

Suitable Material: For waterproof, adhesive, fixed two-component adhesive.

Such as: Crystal or less additive glue --Silicone, epoxy, polyurethane(PU), etc.

Applications:LED products ,Crafts,Electronic components

Such as:Wall washer light, LED bar, LED strip, Ads module, Sensor, Photovoltaic module, Photovoltaic inverter .etc

Applicable materials

1K and 2-component polyurethanes, epoxies, acrylics, silicones, temperature, humidity and UV curing materials. Two component potting materials , 2-part compound materials, AB part compound materials , 2K silicones ,2K epoxies resin, Bi-component PU, Ployerster, Polyurethane, UV materials and so on .

Whatsapp 0086 134 2516 4065

Application:

1.Potting&Encapsulation &Casting: electronics componnets , PCB board, Capacitor, power supply, transformer, ignition coil, reverse sensor, circuit board, filter products ,underwater parts, electronic ballast ,aviation parts, aerospace parts....

2.Dispensing&Dosing : LED strip , led lamp , led bulb , aluminum,led screen , display module ,medical parts,medical liquid filling ....

3.Bonding&doming : LCD screen ,LOCA bonding,ABS plastic,different types of stickers , badge , keychains , souvenirs ,arts , photo frame , and other arts graphics....

China 2 part resin potting machine for automotive Parking sensor potting machinme was added in Oct 2023

China 2 part resin potting machine for automotive Parking sensor potting machinme has been viewed 26 times

20 More Products from Guangzhou Daheng Automation Equipment Co.,LTD :

.jpg)