SMT Online AOI Machine ZW 810

Company Information:

Name: |

SMT Online AOI Machine ZW 810 |

Category: |

|

Offered by: |

|

SMT Online AOI Machine ZW 810 Description:

- Inspection Component: 0201 chip

- PCB size::25x25-480*330mm

- Dimension:900*950*1600 mm

- Weight: 650kg

- Product description: SMT Online AOI Machine ZW 810, Inspection Component: 0201 chip, PCB size::25x25-480*330mm, Dimension:900*950*1600 mm, Weight: 650kg

-

INQUIRY

SMT Online AOI Machine ZW 810

Machine Details:

High efficiency, multi-function, high cost performance

CCD high speed color camera.

A variety of algorithms and technologies are integrated.

Quick programming and debugging integration makes operation more convenient.

Free and simple algorithm combination, the programming interface is more concise and clear.

The front and back of the PCB are automatically identified, making the test more efficient and faster.

Multi-threaded monitoring system, all production line production status is clear at a glance.

A powerful SPC statistical analysis system.

Simple software interface

Intuitive software interface, in line with daily simple and effective operating habits.

Workflow wizard to keep settings consistent.

Comprehensive and flexible software.

The comprehensive application of a variety of practical algorithms, the software runs more flexible.

OCV, OCR character recognition, path test, etc., special coping algorithm, more effective to meet post-print quality inspection, detection rate and pass-through rate is higher.

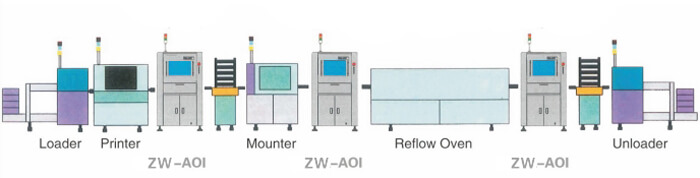

Complete line process improvement program.

The whole line process improvement solution can achieve fine analysis of defects, for example, for the defects found after reflow soldering, the picture of the front of the component and the solder paste can be retrieved, and then the real cause of the defect can be analyzed, so that effective Process improvement program.

The software can not only control the defects caused by the system, but also effectively prevent the defects caused by accidental reasons, so that the process level can be raised to a new level, and the single-digit Dppm can be realized.

ZW-810 technical performance description

|

category |

project |

Specifications |

||

|

visual identification system |

Discriminant method |

Combining weight imaging data difference analysis technology, color image comparison, color extraction analysis technology, similarity, binarization, OCR/OCV, path test and other algorithms |

||

|

Camera |

Gigabit network color high speed camera |

|||

|

Resolution |

10/15/20 micron, dot (optional) standard 20 micron, dot |

|||

|

Light source system |

RGB ring multi-angle LED structure light source, special auxiliary coaxial light source (optional) |

|||

|

Image processing speed |

0201 component |

<7 milliseconds |

||

|

Processing time per screen |

<220 milliseconds |

|||

|

Test content |

Solder paste printing |

With or without, skew, less tin, tin, open circuit, pollution |

||

|

Zero defect |

Missing parts, offset, skew, tombstone, side stand, flip, polarity reverse, wrong piece, broken |

|||

|

Solder joint defect |

Tin, tin, tin, copper foil pollution, etc. (in accordance with ROHS lead-free soldering inspection requirements) |

|||

|

Wave soldering inspection |

Less tin, more tin, solder joint bridging or short circuit, virtual soldering, hollow |

|||

|

Detectable minimum components and spacing |

0201&0.3mm pitch |

|||

|

computer system |

PCB transfer system |

Track height: 900±200mm Substrate fixing method: bottom-up The fixed thimble function corrects the bending of the large plate. Automatic access panel and automatic width adjustment system, in accordance with SMEMA standards. |

||

|

Measureable PCB size |

5 0 × 50 mm ~ 400 x 330 mm (can be customized according to customer requirements) |

|||

|

PCB thickness / weight |

0.3 mm ~ 3.0 mm / 3 kg |

|||

|

PCB warpage |

<2 mm (with fixture assisted correction) |

|||

|

Part height |

The net height is ≤35mm and the net height is ≤70mm (special requirements can be customized) |

|||

|

Minimum part |

0201 component |

|||

|

X, Y platform |

Drive device |

AC servo motor system, Camera moves in x/y direction (PCBA can be fixed to facilitate inspection after solder paste printing and placement) |

||

|

Precise positioning |

<10 micron |

|||

|

Moving speed |

700 mm / sec |

|||

|

Software system |

operating system |

Microsoft Windows XP Professional |

||

|

Identification control system |

Characteristics |

Apply weight image difference modeling technology and unique color extraction analysis technology to learn OK samples, automatically create standard images, identify data and error thresholds |

||

|

AOI program |

Characteristics |

Create standard images in real time, automatically calculate data and error thresholds. Weight imaging data difference analysis technology, learning OK samples, CAD import, test data statistical feedback, standard component library functions. |

||

|

Operation interface |

Graphical programming, WYSIWYG. Chinese/English, Traditional / Simplified |

|||

|

Networking function |

Can be networked with NG terminals, can be checked at REPAIR STATION, repair PCBA error |

|||

|

Control System |

Computer host |

Intel dual-core CPU, 4G DDR memory, 120G solid state drive |

||

|

display |

22-inch LCD widescreen display |

|||

|

Network communication |

Support TCP/IP and Microsoft network system |

|||

|

Other parameters |

Mechanical dimensions |

90 cm × 95 cm × 160 cm (the height includes the foot without a signal light) |

||

|

Gas source |

4-6bar |

|||

|

weight |

About 650kg |

|||

|

power supply |

AC 220 volts ±10%, frequency 50/60Hz, frequency power 1200W |

|||

|

Use environment |

Temperature 10-40 ° C, humidity 30-80% RH |

|||

Keywords:

SMT AOI SPI Machine, SMT AOI Machine, Offline AOI Machine, Inline AOI Machine, SMT X Ray Machine, SMT SPI Machine, 3D SPI Machine, 3D AOI Machine. &

QISMT Co.,ltd provide a full SMT assembly line solutions, including SMT Reflow Oven, Wave Soldering Machine, Pick and Place Machine, SMT Stencil Printer, SMT AOI SPI Machine, SMT Peripheral Equipment, SMT Production line, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: wechat whatsapp:+8617748683433, Skype: qismteric, Email: sales@qismt.com

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is English manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / skype/ phone /trademanager online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

5)Why choose us ?

A. Gold supplier on Alibaba !

B. Trade assurance to US$54,000 !

C. Best price & Best shipping & Best service !

CATEGORIES

CONTACT US

Contact: Eric

Phone: +86 17748683433

Tel: 0755-85225569

Add: No.94, Guangtian Road, Songgang Street, Bao`an District Shenzhen

When SMT matters to your business, partner with QISMT. Where innovation takes form. Mr Eric. sales@qismt.com Wechat whatsapp:+86177 48683433 skype:qismteric

SMT Online AOI Machine ZW 810 was added in Oct 2021

SMT Online AOI Machine ZW 810 has been viewed 58 times

20 More Products from qismt electronic co.,ltd :