Auto Feeding And Loading Full Automatic V-cut PCB Depaneler

Company Information:

Name: |

Auto Feeding And Loading Full Automatic V-cut PCB Depaneler |

Category: |

|

Offered by: |

|

|

View Auto Feeding And Loading Full Automatic V-cut PCB Depaneler |

Auto Feeding And Loading Full Automatic V-cut PCB Depaneler Description:

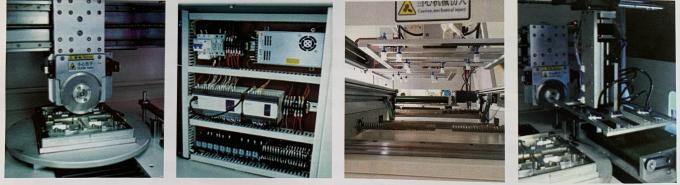

Aull Automatic Inline V-Cut PCB Depaneler

Full Automatic V-cut PCB Depaneler Introduction:

This equipment can further improve the quality of depaneling. It can realize V-groove XY two-way automatic cutting, cutting aluminum & FR4 boards without burr, can connect the assembly line to realize full-automatic depaneling, no need to manually put the board, directly replace the cutter die and suction nozzle when replacing the product, saving time.

Full Automatic V-cut PCB Depaneler Functions:

This machine is used for PCB board depaneling after inserter.

It has the functions of automatic feeding and automatic loading, and the machine is easy to operate.

The setting of each parameter ensures the consistency of the board feeding and the board depaneling.

Precision stepper motor and SMC pneumatic components are used, with high repeatability.

Using Mitsubishi PLC and Taiwan touch screen, the operation interface is simple.

Efficiency: 15s / PC (150x150mm, 8 blade sets).

Safety sensors in working area.

Full Automatic V-cut PCB Depaneler Features:

A single group of multiple cutters can be divided automatically, and different cutters can be made according to different products.

Equipped with acrylic cover to ensure safety.

The electrical control part can be selected in the man-machine interface, convenient to open or shield.

There is a dust collecting tray under the knife mold.

Adopt square welding frame, sheet metal sealing plate, steel paint baking on the surface.

Suitable for all V-groove panels.

Depaneling material: FR, aluminum

Full Automatic V-cut PCB Depaneler Specification:

| Machine Dimension | Name | Inline V-Cut PCB Depanelizer |

| Dimension | 1350*1200*1800mm | |

| Weight | 600kgs | |

| Color | White | |

| Usage Requirements | Power Supply | AC220V, 1800W |

| Air Supply | 0.6MPa | |

| Environment | Clean and dry, avoid humidity or high temperature | |

| Min distance between component and scoring line | 1.5mm | |

| PCB Panel Range | 12x12mm – 300x250mm | |

| Suction | Request min 10x10mm for suction nozzle per each single board | |

| Max component height | Upper 35mm, bottom 20mm | |

| Software | PLC | Local brand |

| Parameter setting | Setting on touch screen | |

| Storage | Available for 50 programs | |

| Touch screen | Taiwan brand | |

| Sensor | Omron | |

| Blade Spec | Material | Japan high steel |

| Angel | 10-30 degree | |

| Life time | 3,000,000 times | |

| Knife mold precision | 0.1mm | |

| Replace knife mold time | 60 minutes | |

| Other Function | Wrong operation protection | Sensor, software |

| Safe protection | Emergency stop switch | |

| Power and gas cut off function | Yes | |

| Self check function | Start up time monitoring, capacity monitoring, equipment fault information and automatic exclusion system |

Full Automatic V-cut PCB Depaneler Cutting Process:

1. The machine is equipped with a cutting die for the lower cutter, the PCB of the upper board mechanism is sent to the predetermined track, the manipulator moves over, and uses the vacuum nozzle to transport the PCB to the cutting die.

2. After the PCB is placed on the cutter die, it moves to the slitting position. The circular cutter slits the PCB. After each cut, the lower cutter die moves to the slitting position again. After all V groove lines in the X direction are cut, the automatic rotation platform rotates 90 degrees to slitting in the Y direction.

3. After the machine cuts the PCB, the cutter die exits, the manipulator moves, sucks up the single PCB and the waste edge at the same time, moves the waste frame to put down the waste, and then moves single boards to the tray of the receiving mechanism to place the product and send it away by the transportation line.

4. There is a vacuum cleaner under the cutter die of the machine to absorb the dust.

Full Automatic V-cut PCB Depaneler Details:

View Auto Feeding And Loading Full Automatic V-cut PCB Depaneler

Auto Feeding And Loading Full Automatic V-cut PCB Depaneler was added in Aug 2021

Auto Feeding And Loading Full Automatic V-cut PCB Depaneler has been viewed 557 times

20 More Products from Winsmart Electronic Co.,Ltd  :

: