Symor Instrument Equipment Co.,Ltd

Climatest Symor® is the leading environmental simulation testing equipment manufacturer in China established in 2001, located at Dayang Industrial Park,Hefei,China.

Symor Instrument Equipment Co.,Ltd(Climatest Symor® below) is the leading environmental simulation equipments manufacturer in China established in 2001s, located at Dayang Industrial Park,Hefei,China.Climatest Symor® has manufactured climate chambers for nearly 20 years,we integrates state-of-the-art test facilities‘ R&D, marketing and production.We have production factories in Hefei and Changzhou cities.Our Changzhou factory covers an area of 12100 square meter,with 1500 sets annual production capability.

Climatest Symor® has initially built ISO9001:2015 Quality Management System. Besides,we insist on the principle "Build trust before business”,Climatest Symor® comprehensively implement the service idea of "stand by customers’ side and consider for them”,we provide one-stop service ranging from custom-made climatic chamber manufacturing,lifetime technical support, to shipping and after-sale service.

We specialize in manufacture and design all kinds of climate simulation test chambers,including Temperature Humidity Chamber,Thermal Shock Chamber,Fast Temperature Change Rate Chamber,Salt Spray Chamber,UV Weathering Chamber,etc,most products are CE certified,which are mainly applied on Electronics,Semiconductor,Automotive,Telecommunications,Chemical,Pharmaceutical,Aerospace,Plastic, Packaging, Photovoltaic industries.we have exported climatic chamber to more than 20 countries during 20 years, our experienced R&D team can entirely settle customers’ special requirements.

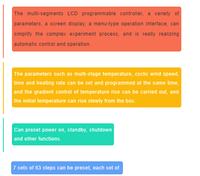

Climatest Symor® brings in advanced manufacturing facilities and technic in China,such as CNC machine,Lathes,Bending machine,Laser cutting machines,etc,which can ensure sate-of-the-art production.we adopts Germany/France imported compressors,well-known brands of LCD controllers,our engineers are well trained with 15-20 years‘ experience in this industry,at present,we‘re developing our exclusive controller,integrating computer control technology with touch screen display for more convenient operation,we aim to manufacture most reliable climate test chambers in China.

Symor Instrument Equipment Co.,Ltd Postings

22 products »

High Temperature Aging Oven is mainly used in the application of rubber and plastic, various insulation materials and products in the cable industry(non-flammable and non-explosive) for drying, high-temperature aging experiment, sterilization and the...

Dry oven is a must instrument in every laboratory,with nearly 20 years efforts and innovation,Climatest now masters core technique of drying oven manufacturing,no matter temperature uniformity or temperature stability.Behind the quality is 1...

Temperature humidity test chamber

Temperature humidity test chamber is to test and evaluate products’ ability to withstand extreme temperature and humidity by simulating different climate conditions,the purpose is to make qualified products. Our Temperature Humidit...

Temperature humidity test chamber

Temperature Humidity Test Chamber can test and evaluate products’ ability to withstand extreme temperature and humidity by simulating different climate conditions,the purpose is to make qualified products by following international standard....

IPX9K Rain Test Chamber (enclosure test)

Climatest Symor® IPX9K Rain Test Chamber(high Pressure high temperature water jet) is for the test of water from all directions and under high pressure aimed at the enclosure. Model...

10%-20%RH electronic dry box for SMD storage

. The whole cabinet adopts 1.2mm galvanized steel with Dupont baking varnish,which is strong corrosion resistant, 3.2mm high intensity toughened glass.reinforced structure,excellent load-bearing and sealing performance. . It adopts US im...

Dry oven is a must instrument in every laboratory,with nearly 20 years efforts and innovation,Climatest now masters core technique of drying oven manufacturing,no matter temperature uniformity or temperature stability.Behind the quality is 1...

UV-Lamp Weathering Test Chamber takes fluorescent UV lamps as light source to simulate the UV irradiation in natural light and condensation to conduct accelerated weathering test on the materials, It simulates UV, rain, high temperature, hum...

1%-5%RH Dry cabinet is especially designed with fully automatic humidity control to prevent moisture related damage.This cabinet is the optimal storage expert for humidity sensitive SMT/BGA/PCB/electronic components.Symor newly-deve...

Desktop drying oven can be used in laboratory or industrial settings for a variety of tasks including evaporation, sterilization, temperature testing, and for incubating temperature sensitive experiments. For details,pls...

28 technical articles »

Factors determine the price of temperature humidity test chamber

Dec 16, 2019 | climatest symor

When we were children,our parents always warn us "Do comparison shopping before you buy",why they say like this?this is a very simple truth, for the first deal,we are always cautious, through continuous comparison in order to find out the best quality, service, after-sale and price. This apply to any industry,there are many manufacturers of environmental test equipment. When some customers inquire a temeprature humidity test chamber, they will find a very common problem. Why is the price of the same equipment quoted by the two manufacturers very different? 1, the chamber body process,which effects the exterior case quality,this price has a gap. 2, the components, esp.components of the refrigeration system, is the core value of the temperature humidity test chamber. 3, even if the body and refrigeration components are the same, some prices are different, that is the manufacturer technical level. 4, regional issues, Wuxi,Changzhou, Dongguan, these brands need to know more. 5. after-sales, a powerful manufacturer often with a sound after-sales service dept.. The above are both technical and service, as well as the delivery cost of goods to the local and overseas are different....

Difference between Neutral and Acid Salt Spray Corrosion Test

Dec 13, 2019 | climatest symor

Salt spray corrosion chamber can test the ability of material and its protective layer to resist salt mist corrosion, or compare the process quality of similar protective layers, at the same time; this equipment is suitable for parts, electronic components, protective layer of metal material and other industrial products. Salt spray test is divided into neutral and acid test. What is the difference between neutral and acid in salt spray test? First, the temperature applied in the test method is different: Neutral test: a. Laboratory:35°C ±1°C, b. Saturated air drums:47°C ±1°C Acid test: a. Laboratory:50°C ±1°C, b. Saturated air drums:63°C ±1°C Second, the production material is different,neutral test chamber adoptes the traditional PVC plates, acid test chamber asopts PP sheet,which is more high temperature resistance and suits strong acid test. Third. Different test methods satisfied Neutral salt spray chamber according to GB/T 2423.17-2008, GB/T 2423.18-2000< basic rules for electrical and electronic products test Ka >, salt spray test method and GB/T 10125-1997, GB/T 10587-2006, GB10593.2-1990, GB/T 1765-1979, GB/T 1771-2007, GB/T 12967.388, GB/T 1705.8-2008, etc. In addition to the test methods specified in the national standard, acid salt spray chamber also needs to expand the standard setting such as IEC,MIL,DIN,ASTM,IS,CNS. Last, Comparison of neutral test solutions China: NaCI distilled water solution NaCI mass concentration (50 ±5) g ≤ l pH value 6.5 ≤ 7.2 United States: distilled water solution NaCI mass concentration 5% ±1% pH value 6.5 ≤ 7.2 Germany: NaCI distilled water solution NaCI mass concentration (50 ±5) g ≤ l pH value 6.5 ≤ 7.2 Japan: NaCI distilled water solution NaCI mass concentration 5% ±1% pH pH value 6.5 ~ 7.2 France: NaCI distilled water solution NaCI mass concentration 5% pH 6.5 ≤ 7.2 https://climatechambers.com/articles&latestnews/difference-between-neutral-and-acid-salt-spray-corrosion-test.html...

What causes temperature humidity chamber to alarm?

Dec 12, 2019 | climatest symor

Today we discuss the reason that causes temperature humidity chamber to alarm,In most cases, the equipment alarm is caused by the improper operation in the process of use, which mainly includes following reasons:that are refrigeration system, temperature system and circulating system. First, Refrigeration system 1, refrigeration compressor overpressure alarm. If the refrigerant pressure exceeds the set value, it will stop and alarm at the same time. At this time, the fault must be eliminated and then manually reset. 2, short phase power supply, phase sequence alarm. When the external power supply of the equipment is out of phase or the phase sequence is changed, it will stop and alarm at the same time. 3. The circulating cooling water is short of water to alarm. When the water pressure of the cooling circulating water system is insufficient, it will stop and alarm at the same time, and it must wait for the fault to be eliminated and reset at the same time before it could run normally. 4, refrigeration compressor overheating alarm. When the coil of the compressor is overheated and the power supply of the line is not normal, it will stop and alarm at the same time. Second, Temperature system 1, the overtemperature alarm in the chamber. The sensors in the channel and the sample area are equipped with overtemperature protection devices, and there are also overtemperature protecter on the control panel. When the temperature in the working chamber exceeds the setting value on the controller, it will stop and alarm. 2. sample overtemperature protection. When the temperature in the sample area exceeds the protection temperature set by the controller, it will stop and alarm at the same time. The overtemperature protection of the sample is divided into upper limit protection and lower limit protection, which can be set according to the demand, Third,Circulating system 1. The alarm is caused by the overheating of the circulating fan. When the coil of the fan is over-heated, the alarm will be stopped at the same time. 2. The fan over-current alarm. When the current of the fan exceeds the allowable value, the alarm is stopped at the same time, and the normal operation can only be carried out after the fault maintenance of the overcurrent is completed. This is what we talk about today,if you have more questions,let us know....

Why salt spray chamber fail to spray salt mist?

Nov 20, 2019 | climatest symor

Salt spray test chamber is used to test teh salt corrosion resistance ability of hardware, metal and other auto parts,the chamber can quickly detect the corrosion resistance degree of products in the temperature, humidity and salt spraying environment, which can effectively improve production efficiency. So what is the reason why such a salt spray test chamber does not spray? As per our past maintenance experience,there are below reasons,customers can have a look,hope it is helpful: 1, the spray tower is blocked; 2, water pipes clogged, water flow can not go in; 3, the air compressor stops running,pls open the air compressor button; 4, main switch of the air compressor outlet is not turned on,pls turn on. 5, the solenoid valve fails, the pressure meter is broken or the pressure is too low, pls check with Climatest and repair it. 6, when the nozzle is clogged, the nozzle should be carefully removed and cleaned,because it is fragile. 7, if the spray pressure is normal, the position of the nozzle glass is also correct, but what is the reason for not spraying? In this case, it is necessary to carefully observe whether there is dirt at the contact surface of the nozzle. If so, clean up the dirt and the spray can be carried out normally. That‘s all we‘re going to talk about today. If you have any questions, follow us on facebook, Please feel free to ask us questions....

Maintenance and operation of walk-in temperature humidity test chamber

Nov 17, 2019 | climatest symor

Overview of walk-in temperature and humidity chamber: It also belongs to environmental test equipment, it tests whether the product can resist high temperature, low temperature, humidity, or the physical and chemical changes produced under extreme conditions, the walk-in temperature and humidity chamber volume is large, the product is placed, or a large object can be placed, such as automobile, new energy, television and liquid crystal screen, etc. How to do the routine maintenance of the walk-in temperature and humidity chamber: 1. The wet gauze basically, if there is no special case, s/b usually changed once in 3 months 2. The water channel shall be regularly cleaned, including water cup, water tank, etc., so as to prevent the water from being blocked,affect the humidity test. 3. It is forbidden to test the flammable and explosive products inside working room. 4. Clean the chamber on a regular basis 2. How to operate walk-in temperature and humidity chamber: The operation method is same as standard temperature humidity test chamber,the controller is 7-inch LCD programmable color screen, you only need to setthe temperature point---test time--how many cycles need to be tested, This can be done automatically, and the machine will stop automatically when it is complete. If there is any problem during the operation, the corresponding problem point will be displayed on the machine control screen. Walk-in temperature and humidity chamber is a must equipment for reliability test of Automobile,Aerospace,Electronic parts,etc,the operation and maintenance are easy,it is teh tear down mahcine,Climatest engineers will be dispatched to do on-site support,for instance,we will finish commissioning,train customers how to operate,maintain,welcome to follow our company facebook page:https://www.facebook.com/Climatechambers...

Material Aging Test-UV Weathering Test Chamber

Nov 15, 2019 | climatest symor

Material Aging Test-UV Weathering Test Chamber 1.What is UV aging? UV aging chambers use fluorescent ultraviolet lamp as light source to simulate UV radiation and condensation in natural sunlight, and to carry out accelerated weather resistance test in order to obtain the result of weather resistance of the material. UV aging detection is widely used in non-metallic materials, organic materials (such as coatings, paints, rubber, plastics and their products) under the change of sunlight, humidity, temperature, condensation and other climatic conditions to test the aging degree and situation of related products and materials. 2.Why we should do UV aging test? When the product is placed in the ambient environment, there will be different problems taken place, such as appearance changes, including cracking, speckle, powdering or color change, and even performance degradation,which may be due to the loss of components in the resin resulting in chemical bonds changes inside the molecular structure, this is mainly caused by sunlight, industrial exclusion of waste gas, bacteria and so on. The aging performance of the product directly affects the lifespan of the product, so aging test become significant,non-metallic materials, organic materials (such as paints, paints, rubber, plastics and their products) are subject to changes in sunlight, humidity, temperature, condensation and other climatic conditions to test the degree and condition of aging of related products and materials. The natural aging test is to put the plastic specimen under the sun exposure, and it is directly under the natural climate environment,to test the material performance under various factors such as light, heat energy, atmospheric humidity, oxygen and ozone, industrial pollution and the like, the most harsh climate condition should be selected,or near the actual application area of the material, the test site shall be open and flat, no obstacle to affect the test results,the specimen holder shall be facing the equator and at an angle of 45 ° from the ground. When the main performance index of the specimen has been reduced, the test s/b terminated when it achieve the minimum allowable use value . in most case,the test is terminated when the product primary performance index falls to 50% of the initial value. The natural aging process is a very slow process, and there is a great difference in different geographical conditions, which brings difficulties to evaluate the aging resistance of the product. It is an attempt to make an evaluation of the aging performance of the plastic in a shorter time,that is accelerated aging test. The accelerated aging test can be used to simulate the human light source of the fluorescent lamp, including the carbon arc lamp, the xenon arc lamp and the fluorescent ultraviolet lamp, and the artificial light sources can generate more light than the natural sunlight on the ground. When these artificial light sources are used, it is also common to use the combination of the condenser to simulate the rain drop, the dew and the like to conduct the aging test on the product....

Nov 13, 2019 | climatest symor

Dry oven is a must instrument almost for every laboratory in different industries,with nearly 20 years efforts and innovation,Climatest now masters core technique of dry oven manufacturing,no matter on temperature uniformity or temperature stability.Behind the quality is 15 years of consistent persistence,strong belief in excellence; from design to R & D to production, from promotion to sales to installation; every step should reach excellence,What you see, you use our products, you choose, you feel that we do our best,this is our faith. Dry Ovens are used to dry or temper electronic components,material tests,torrefaction, wax-melting ,high temperature aging ,preheating and sterilization in industrial and mining enterprises, laboratories and scientific research institutes. .Exterior chamber is made by reinforced steel with painting; working chamber made by anti-corrosion stainless steel SUS#304 .Intelligent PID control, LED controller with over-temperature alarm,timing range within 0~9999min .Hot air circulation system composed of Germany imported low-noisy air blower and optimal air duct which ensure uniform temperature distribution .Double layers of glass door, large transparent window to observe specimen .Forced air convection Climatest manufactures desktop and floor-standing models with RT+10°C-200°C,250°C,300°C,350°C,400°C temperature range,and customized as per special requirement,if you wanna know more details about our dry oven,please visit our product page:https://climatechambers.com/industrial-dry-oven/200-degree-c-hot-air-oven.html...

How to inspect the temperature recovering time of thermal shock chamber?

Nov 12, 2019 | climatest symor

Thermal shock test chamber can be used for testing the chemical change or physical damage on composite materials caused by the thermal expansion and contraction of the sample in the shortest time,which is subjected to extremely and continuous high and low temperature environment.so how to check the temperature recovery time of this chamber? Normally we take following steps to inspect the temepratuire recovering time: 1.Install the temperature sensor at the specified position, and adjust the temperature controller of hot zone and cold zone to the required nominal temperature respectively. 2.The temperature increases and reduces respectively,30min after temperature in two zones reach stable status,record temperature value of the measuring point,pls set the temperature value of two zones to be required nominal temperature. 3.The temperature shock test chamber automatically places the inspected load into theh ot zone,select the corresponding retention time according to regulated standard. 4.Set the transfer time,then the inspection load is transferred from hot zone to cold zone, and the temperature of the measuring point is observed and recorded, and then the reverse conversion of the load from cold zone to hot zone is carried out according to the same method, and the temperature of the measuring point is observed and recorded. www.climatechambers.com...

When you pull out the nitrogen pipe of nitrogen cabinet

Nov 07, 2019 | climatest symor

Many customers who have purchased the nitrogen cabinets have been in the mistaken belief that the air pipe can be pull down hard,so that it can cause the board to be damaged due to the hard pulling of the air pipe, which leads to the replacement of the penetrating board. Now, the following pictures are provided. Please note: Nitrogen cabinet is a optiomal choice for the microelectronics,semiconductor for humidity proof and anti-oxidation purpose,Climatest has put much efforts on the R&D of dry cabinets,as you know,our advangtage is to handle temperature and humidity,since early 1990s,our engineers began to test and research dry cabinet and nitrogen cabinet,all of our manufacturing process strictly follow ISO9001 standard,we supply to international customers for 20 years,if you are still looking for a reliable dry cabinet manufacturer to protect your MSD from moisture related damage,come to visit www.climatechambers.com,we are ready!...

Why we need to proceed temperature humidity test?

Oct 29, 2019 | climatest symor

For every 10 ℃ increase in temperature, the reaction rate is twice to three times. This means that for every 10 ℃ increase in temperature, the life span of the product will be halved, and when the temperature rises by 20 ℃, the life span of the product will be reduced to 1/4. High temperature will lead to aging, oxidation, evaporation, physical deformation and so on. Low temperature will lead to embrittlement, ice formation, viscosity and solidification degree, loss of mechanical strength, physical shrinkage and so on. When the product is shipped, stored and operated in the environment, it will be endangered. In addition, each product has regulatory and certification requirements, and it is important to evaluate reliability and durability before it is put on the market. In general, according to the IEC60068 test standard, it requires the volume of the laboratory to be at least five times the total volume of the sample under test. Haida constant temperature and humidity box can help you meet this demand. So with the fast developmement of manufacturing industry,test becomes a necessity to see wether the product is able to meet regulated standards in R&D satge,Climatest Symor specializes in handling temperature and humidity,we supply environmental test chamber to China State-owned Research Institutes and laboratories,and obtain excellent reputation from international cllients,our company put much efforts on chamber R&D ,striving to supply best-quality climate simulation equipment and after-sale service. For details,pls visit our official website www.climatechambers.com...

18 more technical articles from Symor Instrument Equipment Co.,Ltd »

10 news releases »

Status quo and trend of environmental testing instrument Industry in China

![]() Dec 26, 2019 | Status quo and trend of environmental testing instrument Industry in China

Dec 26, 2019 | Status quo and trend of environmental testing instrument Industry in China

Symor Instrument Equipment Co.,Ltd Releases New Environmental Test Chambers

![]() Dec 10, 2019 | Company owners can now enjoy the various environmental chambers presented by Symor instrument Equipment Co.,Ltd, which includes Temperature Test Chamber, Temperature Humidity Chamber,IP Test Chamber,Ozone Aging Test Chamber, and Salt Spray Corrosion Test Chambers, etc.

Dec 10, 2019 | Company owners can now enjoy the various environmental chambers presented by Symor instrument Equipment Co.,Ltd, which includes Temperature Test Chamber, Temperature Humidity Chamber,IP Test Chamber,Ozone Aging Test Chamber, and Salt Spray Corrosion Test Chambers, etc.

![]() Nov 28, 2019 | Climatest will also launch new products one after another during 2019-2020

Nov 28, 2019 | Climatest will also launch new products one after another during 2019-2020

Professional team for humidity control dry cabinet research

![]() Nov 26, 2019 | Climatest is a professional team engaged in humidity control dry cabinet research

Nov 26, 2019 | Climatest is a professional team engaged in humidity control dry cabinet research

![]() Oct 29, 2019 | Fast dehumidifying series dry cabinet announced!

Oct 29, 2019 | Fast dehumidifying series dry cabinet announced!

The Development of Instruments moves towards Intelligence

![]() Oct 18, 2019 | As an important basic industry of Chinese manufacturing industry, the intelligent direction of instruments is miniaturization, multi-function, artificial intelligence and virtualization.

Oct 18, 2019 | As an important basic industry of Chinese manufacturing industry, the intelligent direction of instruments is miniaturization, multi-function, artificial intelligence and virtualization.

Hot air dry oven for PCB baking

![]() Sep 25, 2019 | Air forced dry oven for PCB mosture removal

Sep 25, 2019 | Air forced dry oven for PCB mosture removal

The new fast dehumidifying dry cabinet series release

![]() Jun 10, 2019 | Climatest Symor launched the new fast dehumidifying dry cabinets,the moisture can lower to <5%RH within 30 minutes(unload,ambient 25C,60%RH)

Jun 10, 2019 | Climatest Symor launched the new fast dehumidifying dry cabinets,the moisture can lower to <5%RH within 30 minutes(unload,ambient 25C,60%RH)

![]() May 14, 2019 | Test is for your progress!

May 14, 2019 | Test is for your progress!

Temperature cycle machine for IC package reliability test

![]() May 08, 2019 | Temperature cycling machine,we also call it thermal shock chamber,it's widely applied in semiconductor manufacturing industry.

May 08, 2019 | Temperature cycling machine,we also call it thermal shock chamber,it's widely applied in semiconductor manufacturing industry.

1.jpg)