Cartridge Expulsion Unit A90 CV

Company Information:

Name: |

Cartridge Expulsion Unit A90 CV |

Category: |

|

Offered by: |

|

Cartridge Expulsion Unit A90 CV Description:

Up to 90 Percent Less Material Waste per Cartridge Change

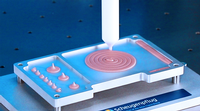

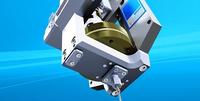

Scheugenpflug has further developed the proven material feeding unit for dispensing applications with high viscosity materials and low media consumption: The new A90 CV not only ensures a process reliable and failure-free feed of potting material from the cartridge to the dispenser. The new vacuum docking function also reduces material waste per cartridge change by up to 90 percent thanks to a patented docking sleeve.

For adhesive bonding, sealing and thermal management tasks with low media consumption, material is usually provided with commercial cartridges. Here, optimally tailored feeding systems are in demand which guarantee a gentle and constant material feed – even when processing small volumes. For these applications, Scheugenpflug has further developed its proven A90 C cartridge expulsion unit.

The A90 CV not only guarantees a reliable and failure-free feed of highly viscous media to the dispenser, but also features the new vacuum docking function. For the first time, this enables the automated ventilation during cartridge changes and thus an absolutely bubble-free docking process of the material cartridge to the dispensing system. So far, freshly mounted cartridges had been ventilated manually, meaning that the accompanying material loss was dependent on the routine and experience of the respective operator. Since this process happens automatically now when using the vacuum docking function, the material waste per cartridge change can be reduced by up to 90 percent. In addition to maximum process reliability, users also benefit from significant cost savings – especially when using very expensive dispensing materials.

A patented docking sleeve with filter was developed

In order to realize the new function, a patented docking sleeve with filter insert has been developed. The use is quite simple: The sleeve is manually put on the filled material cartridge, which is then inserted into the cartridge mount of the A90 CV. An ejector is used to evacuate the docking sleeve. The integrated filter insert prevents the introduction of dispensing material into the ejector line. High user-friendliness is ensured by additional functions of the system control unit, which support the operator with a fast and fault-free cartridge change.

A new process video for the A90 CV illustrates how vacuum docking works. The video can be found under the following link: www.scheugenpflug.de/en/a90-c; for additonal information go to www.scheugenpflug-usa.com.

Cartridge Expulsion Unit A90 CV was added in Aug 2018

Cartridge Expulsion Unit A90 CV has been viewed 536 times

13 More Products from Scheugenpflug Inc. :