AO1000 - Anti-Oxidant Solder Additive

Company Information:

Name: |

AO1000 - Anti-Oxidant Solder Additive |

Category: |

|

Offered by: |

|

AO1000 - Anti-Oxidant Solder Additive Description:

Solder additive to aid in reducing the solder dross buildup in both static and wave soldering pots containing SN100c. AO1000 can reduce solder usage by as much as 50%.

FCT Assembly has developed AO1000 Anti-Oxidant Solder Additive to aid in reducing the solder dross buildup in both static and wave soldering pots containing SN100C. Dross buildup can seriously affect the wetting abilities of the solder and can cling to component leads when they are removed from the bath. Use of AO1000 Solder Additive also will reduce the loss due to dross formation, which can reduce solder usage by as much as 50%.

AO1000 Solder Additive is added to the solder bath at the prescribed level and within a short time the oxides rise to the surface and can be removed. This leaves a surface protected by a thin, colorless film that will reduce further dross formation. No oxide remains on the solder surfaces, which stay, smooth and shiny. AO1000 Anti-Oxidant Solder Additive will protect a solder bath up to temperatures of 371°C (700°F). It is not recommended to exceed a solder pot temperature of 265°C. The anti-oxidant will oxidize faster at temperatures higher than this.

Use of AO1000 Anti-Oxidant Solder Additive offers the following advantages:

- Lead Free

- Less dross formed

- Better wetting

- Smooth, bright fillets

- Lower solder use

- Safer than chemical treatments

- Less mess than oil covers

Application

For static solder pots: Maintain the level of control by adding 1-50g slug per 5 pounds of solder in the solder bath. If multiple slugs are to be added, then add one every 15 minutes, to give time for

the AO1000 to dissolve.

For wave solder pots: Maintain the level of control by adding 1-1000g Bar for every 500 pounds of solder in the solder pot. Additions should be made in the side pot, and not directly into the wave.

Recommendations:

It is recommended to maintain a light dross covering on an SN100C solder pot. This will help to maintain the antioxidant content. The dross should also be perforated with a spatula periodically. This will help to return some of the anti-oxidant to the molten solder.

Packaging:

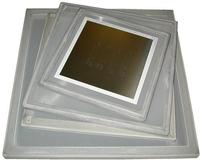

AO1000 Anti-Oxidant Solder Additive are offered in two sizes:

- 250 gram plastic jar containing 5- 50g slugs

- 1000g Bar

Buy FCT Assembly's lead-free solder products and superior quality stencils at the new Online Store »

AO1000 - Anti-Oxidant Solder Additive was added in Apr 2012

AO1000 - Anti-Oxidant Solder Additive has been viewed 1005 times

13 More Products from FCT ASSEMBLY, INC. :