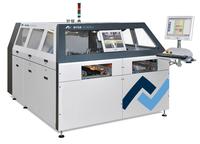

Ersa HR 600/2 Hybrid Rework System

Company Information:

Name: |

Ersa HR 600/2 Hybrid Rework System |

Category: |

|

Offered by: |

|

Ersa HR 600/2 Hybrid Rework System Description:

Ersa HR 600/2 – optimized, automatic component placement and precise temperature process control for all SMDs.

The task formulated for the Ersa HR 600/2 Hybrid Rework System was to offer professional, automated rework of sub-assemblies for the electronic industry. With the system now at hand, almost all high pin-out components that may be found on modern board assemblies, and of virtually any shape, can be reliably reworked. The core competencies of this universal rework system are the placement of components, their lifting off and their controlled setting down, as well as the soldering process.

Special attention was placed on the automation of the individual process steps. All operations can be controlled in a step-by-step mode by the operator himself, or they can be combined to automated operation, requiring very few interventions by the operator.

To preheat the complete board area of the assembly mounted in the board holder, the system utilizes highly dynamic IR-heating elements in the lower heater cassette. A hybrid heating head combines the heat transfer method of IR radiation with that of convection heating for a targeted, and therefore highly efficient, warming of the components to be worked on. Applying this method, quick and top-quality desoldering and soldering result are being achieved. An optional Reflow-Process-Camera (RPC) with LED illumination is available for process monitoring and documentation. Placement of the components is a largely automatic process; the integrated image processing software assesses data of images generated by the two cameras installed. The required component position is automatically calculated, and the component is placed, independent of an operator, using a vacuum pipette mounted on an axis-system.

The system is prepared for the mounting of the Ersa Dip & Print frame. Printing the solder paste onto the component takes place externally on the Dip & Print Station; dipping the component into the flux depot is equally a fully automated process.

Highlights:

- Highly efficient 800 W hybrid heating head

- Homogeneous, large-area IR bottom heating with 3 heating zones (800 W each)

- Automatic and precise component alignment with the help of machine vision

- Highly accurate, motor-driven axis system for component placement (+/- 0.025 mm)

- User independent, reproducible repair results guaranteed

- Process control and documentation via the operator software HRSoft

- Fully automatic or semiautomatic operation

- Suitable for the use of the Dip&Print Station

Ersa HR 600/2 Hybrid Rework System was added in Nov 2020

Ersa HR 600/2 Hybrid Rework System has been viewed 657 times

19 More Products from kurtz ersa Corporation :