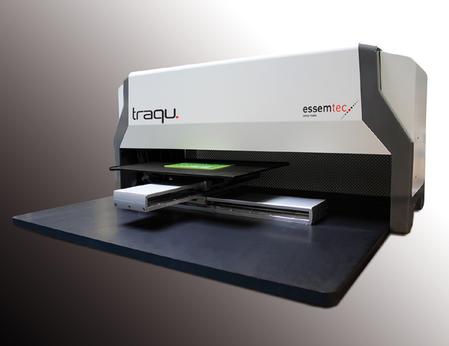

Traqu is a high-resolution digital 3-D inspection device from Essemtec used for 3-D measurement and analysis in processes such as solder paste inspection (SPI). Measurement tasks are programmed with a few mouse clicks, and DXF and Gerber data can be imported.

Simplified programming by DXF or Gerber data import

Traqu is not a traditional AOI but rather a 3-D inspection system for process optimization, monitoring and sample control. The infrared-interferometric sensor scans any 3-D structure, independent of material and surface. Depending on installed lenses, vertical resolution from 2-200 nm and a horizontal resolution from 1-20 µm can be achieved.

Traqu applications are versatile. In electronics production, Traqu is used for SPI and quality insurance for stencil printers. Solar cell manufacturers can measure the cross section of bars and fingers. LED manufacturers can measure the form and volume of dispensed lenses. Traqu can analyze any 3-D surface as well as measure coating thickness.

Programming and analysis are simple due to the simple Traqu software. The substrate layout is either imported from DXF or Gerber data or taught-in manually. The scan area is marked by drawing a box around it with the mouse. For PCB inspection, Traqu can be set to automatically scan all packages of the same type.

The desired type of analysis, measurement, calculation and result display is stored in a recipe for later reuse. The area of inspection covers 300x400 mm. Additionally, a flexible magnetic holder is integrated for any substrate type.

The Swiss machine manufacturer Essemtec is a market leader in manufacturing flexible production systems for industrial users. Essemtec has been developing, manufacturing and marketing equipment and machines for all processes in the electronics industry since 1991: printers, dispensers, pick-and-place and soldering systems. Manual, semiautomatic and fully automatic systems are available. The range of products also includes transportation and storage systems, as well as software solutions for planning, simulation optimization and documentation of manufacturing. All Essemtec systems are optimized for maximum flexibility. Users can switch from one product to another quickly, making maximum use of available production capacity. Essemtec - Be more flexible.

.gif)