Reinhausen Plasma will be at the productronica where it will be presenting the world’s very first process for chemical-free and energy-saving metallization and coating for a multitude of different materials - its nano-powder deposition technology, Plasmadust for short. This innovative technology enables coating processes that are not only quality and cost optimized but also environmentally sound and that can be used in the electronics industry, the photovoltaic and semi-conductor industries, light-weight constructions for the car industry and many, many more applications. At the same time it opens up a range of completely new applications.

The Plasmadust technology developed by Reinhausen Plasma GmbH is based on a combination of cold-active plasma and nano or rather micro-powders. For the very first time coating processes using metal, polymer, semi-conductor and other coatings can be carried out directly on two and three-dimensional substrates made of metal, plastic, silicon, glass, ceramic, paper, board and textiles with this new technology in a process that is completely free of chemicals, in other words VOC-free. It also eliminates the need for the etching and acid cleaning processes that are normally indispensable in classic surface processing.

Layer deposition using cold-active plasma

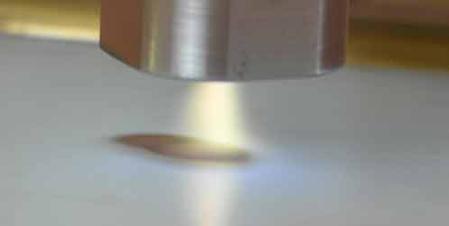

The company in Regensburg uses the plasma generator Plasmabrush PB2, its own in-house development, for layer deposition with the Plasmadust process, a generator that operates under atmospheric pressure. However, unlike conventional atmospheric-pressure plasma systems, the plasma gas is not generated in an oscillating circuit but on the basis of the inverter principle by means of highly effective, pulsed arc discharges. This generates non-thermal plasma whose measurable temperature of 120 °C is made possible by the imbalance of the energy content of light electrons and heavy gas particles under atmospheric conditions. Compared to other well-known processes such as plasma/flame spraying, this results in considerably lower thermal stressing of the basic substrate. The particle speeds of the Plasmadust process are also lower than those of other processes such as cold gas and plasma spraying.

The continuous and agglomerate-free feeding of the coating powder, which has a particle diameter of 100 nm to 20 µm, is carried out by a specially developed atomizer/conveyor technology. An adjustable and uniform particle flow ensures even and repeatable layer thicknesses.

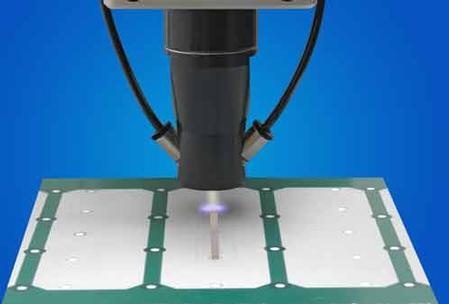

The physical properties of the plasma together with ideally adjusted powder feeding make it possible to deposit cohesive layers on even extremely thin and/or temperature-sensitive substrates such as plastics, films and paper with the Plasmadust process. The repeatable layer thicknesses lie in a range of between 1 and 100 µm with a processing speed of up to 150 meters a minute. Porosity can be set to between 1 and 30 percent. Depending on the type of powder, a coating path width of up to 10 mm can be achieved with a plasma generator. Generators can be used in a scanning process or several of them can be arranged in parallel and/or offset to each other for the coating or metallization of larger surfaces.

Potential for coating processes where quality and costs are optimized

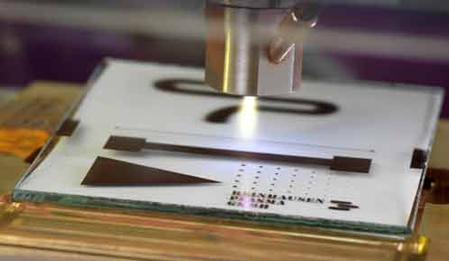

Practically any materials that can be pulverized and melted are suitable as coating materials; these include salt, gold, copper, aluminum, tin, bismuth, tellurite, CIGS, polymers, thermoplastics, glass and ceramic materials. Salt as a fluxing agent, for example, can be deposited in a dry and controllable process. In the case of printed circuit board (PCB) production, Plasmadust technology makes it possible to apply circuit paths directly onto the board with the aid of a template. Shorter production times and the use of cheaper plastics add up to great cost saving potential. Other examples of applications for Plasmadust technology include ecological and efficient wafer coating, metallization and contacting of solar cells, the manufacture of flexible circuit boards and coatings for EMC shielding. Even semi-conductive materials such as bismuth and tellurite can be deposited, for instance for electrical switching systems and the cost-efficient manufacture of generators in thermoelectric applications. Deposition of a primer layer on rubber and caoutchouc surfaces for metal/rubber composite systems is possible, as is the creation of functional and decorative layers. In addition alloys and material composites such as carbon/metal, which cannot be treated with conventional coating processes, can also be deposited.

High cost effectiveness thanks to energy-efficient coating The highly reactive micro or nano-powders melt at low temperatures so that the coating process requires considerably less power when compared to conventional processes. The oating/metalllization of a surface of one square meter, for example, consumes only from 1/10 to 1/100 of the energy required for thermal spraying processes.

The Plasmadust system can be integrated into production lines just as simply and quickly as it can into roll-to-roll processing systems.

About Reinhausen Plasma GmbH

Reinhausen Plasma GmbH is a subsidiary of Maschinenfabrik Reinhausen GmbH, the worldwide market leader and leader of technology for the regulation of high-power transformers that is also located in Regensburg. We see ourselves as an innovative supplier of plasma solutions for surface finishing and coating. The company sets new standards in cleaning and surface activation with plasma with the development of its cold-active atmospheric-pressure plasma tools plasmabrush and piezobrush, whose outstanding features include low operating temperatures, slow gas speeds, extreme accessibility of gaps and contours by the plasma and their high degree of gas purity. For the very first time the patented plasmadust process enables energy-efficient coating of 2 and 3-dimensional components made from almost all materials without the need of any solvents or chemicals (VOC-free).