Exceptional Volumetric Dispense Control with No Drip or Drool

Advanced dispense technology is available for integration into your dispensing system. Continuously Volumetric, drip-and-drool free dispense technology can now be retrofitted into your dispense robot. GPD Global's Volumetric PCD pumps ensure the success of applications like underfill, LED encapsulation, solder mask, silicones, conductive ink, conformal coatings, and more. Improve your throughput and yields by retrofitting a Volumetric PCD Pump into your dispense system to simplify the dispense process.

Progressive Cavity Displacement (PCD) Technology is a true continuous volumetric dispense technology. It accommodates a wide range of fluid viscosities - from water to mid-viscosity pastes. With a completely sealed system, these Volumetric PCD pumps do not drip nor drool.

Three models of PCD pumps are available for integration into your system with small or large volume requirements. The smallest model dispenses volumes down to 0.5 μl, while the largest model dispenses at rates up to 16 ml/min. You can easily retrofit your dispensing system with Volumetric PCD using an integration kit that includes all hardware required (Figure 1): a PCD Series Volumetric Pump, a Programmable Controller, an Interface Cable, a Mounting Bracket, and a PCD Support Kit.

The programmable controller can be triggered with an external signal through a user-sourced cable. The signal may originate from a Programmable Logic Controller (PLC) or another automated system (Figure 2).

A reverse or suck back volume is available in each of three programming modes: Quantity, Time, and Start/Stop. For programming consistency, users can save 24 programs to an SD card for transfer to other controllers.

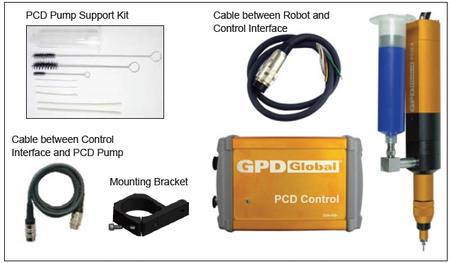

Alternatively, Direct Control Integration offers the greatest flexibility by giving you access to all aspects of the motor/pump control. The user sets up this programming interface. The Direct Control Integration Kit includes all hardware needed (Figure 3): a PCD Series Volumetric Pump, a Control Interface, a cable

between controller and pump, a cable between controller and robot, a Mounting Bracket, and a PCD Support Kit. Read more about Volumetric PCD Pump Integration.

GPD Global is an equipment manufacturer of high-quality, precision, automated fluid dispensing and component-prep systems. The company is an international, state-of-the-art equipment supplier for the PCB assembly and semiconductor industries. It designs and manufactures a variety of automatic fluid dispense systems, as well as manufactures an SMT Cover Tape Peel Tester and Component Prep equipment for Thru-Hole applications. GPD Global is committed to offering premium service to its customers and has sales and customer support affiliates located throughout the world, including North America, South America, Europe, the Middle East and Asia-Pacific.

»

»