NEO Tech, a leading provider of manufacturing technology and supply chain solutions for brand name OEMs in the industrial, medical and mil/aero markets, announces that it will showcase its high-reliability substrate and microelectronic assembly capabilities in booth 2143 at the 2016 IEEE International Microwave Symposium IMS 2016, which is schedule to take place from May 24-26 at the Moscone Center in San Francisco.

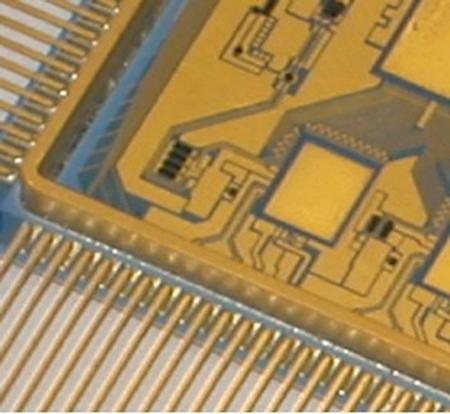

NEO Tech is North America’s leading manufacturer of quality low-temperature co-fired ceramic (LTCC) and high-temperature co-fired (HTCC) substrates and packages. These fabrication technologies provide unique solutions for high interconnect density, compact networks and high-frequency applications. Additionally, the company will discuss its microelectronics assembly services, which include package assembly, sealing and testing. With more than 40 years of experience in high-reliability hybrid and RF technologies, NEO Tech has emerged as North America’s largest microelectronics assembly services provider.

During the symposium, NEO Tech will feature a range of its LTCC, HTCC and hybrid substrates, and microelectronics packaging technologies:

-

Ceramic Substrate manufacturing: thick film, ECP thick film, BeO substrates, plating and HTCC/LTCC board fabrication.

-

LTCC systems: DuPont 951, 9K7, and 943; Ferro A6M, A6S, and L8; and gold, silver and mixed metal systems

-

HTCC systems: multiple AlN tape systems and thermal conductivity >150 W/mK, Tungsten metallization electro-less plated with Ni-Au

-

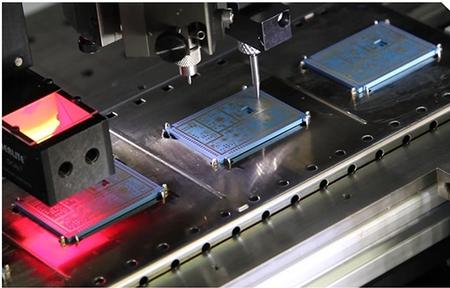

Innovative AUTOLINE to economically produce complex RF microelectronic packages

The company’s microelectronics facilities produce products and assemblies for a wide variety of OEMs in medical, telecommunications, and defense markets. The microelectronic industry faces the challenge of controlling costs and risk while ensuring reliability, and the company has thrived by offering customers an unmatched understanding of materials, production equipment, standardized processes, and defect-elimination approaches.

For more information about NEO Tech and/or the products and services that will be highlighted during the IMS 2016 IEEE MTT-S International Microwave Symposium, visit the company’s Web site at www.NEOTech.com.

NEO Tech combines the strengths of three leading contract manufacturers: NATEL, EPIC, and OnCore. With over 40 years of heritage in electronics manufacturing, NEO Tech focuses on low-medium-volume/high-mix, high-complexity products primarily in the medical, defense/aerospace and industrial markets.

NEO Tech is favorably positioned among mid-tier EMS manufacturers to “make amazing things happen.” NEO Tech offers full product lifecycle engineering services, manufacturing and testing of microelectronics, cable & harness interconnect products, PCBA, full box build services and aftermarket repair and fulfillment services. The companies that form NEO Tech have been known for solving tough engineering problems that result in high-reliability, high-quality electronic solutions for customers.

Headquartered in Chatsworth, CA, NEO Tech has manufacturing and engineering locations in California, Colorado, Illinois, Massachusetts, Nevada, Ohio, Tennessee, Mexico, and China. NEO Tech holds and maintains industry specific certifications that include ISO9001, AS9100, ISO13485, ISO/TS16949, ISO14001 and MIL-PRF-38534. To learn more, visit www.NEOTech.com.