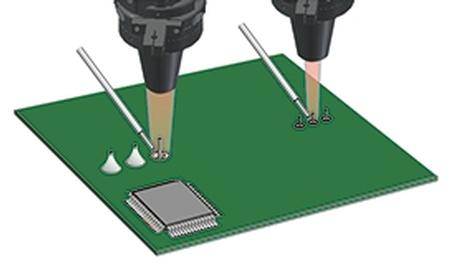

Japan Unix, a solutions provider for manual and soldering automation, announces that Multi-ɸ (Phi) Laser Soldering now is available. The variable laser spot diameter system optimizes soldering conditions for each component.

The Multi-ɸ Laser is a practical product for laser soldering users. When hand soldering, operators consider tip sizes/shapes. Now, with Multi-ɸ, they can do the same with laser. Multi-ɸ optimizes laser exposure diameters to fit any component size or board patterns. Laser beam spot diameters are adjustable without moving. The variable spot diameters allow ideal soldering outcomes to diverse component shapes or various land patterns. Both quality and speed are enhanced because optimal conditions are designed to each component.

Benefits of Multi-ɸ Laser Soldering include:

• Immobile: Beam spot diameters are adjustable within a 0.1-3.0 mm range. The diameter range is determined by optical fibers and lens configuration. The laser’s output power is efficiently converted into thermal energy, and the robot’s z-axis (vertical) stays fixed when adjusting the beam diameter.

• Flexibility: Multi-ɸ supports a variety of soldering patterns, components shapes and sizes. Additionally, it supports various soldering patterns, provides optimal soldering conditions for all patterns and feeds solder wire from any direction with the new feeding mechanism.

• Optimization: Provides optimal conditions for all patterns, which improves quality and cycle time. By optimizing soldering conditions for the entire circuit board, the equipment achieves the shortest laser irradiation period. Mixed-component assembly PCBs now can be processed with just one machine.

Replacement laser heads are now available for existing laser soldering customers. Contact Japan Unix at www.japanunix.com to find out how to refine and improve your existing equipment. To find out more about Multi-ɸ Laser Soldering, visit https://www.japanunix.com/en/products/laser/multi-phi.php.

Japan Unix was established in 1974 in Tokyo and has specialized in the soldering automation industry since its startup. A manufacturer and integrator of robotic soldering, Japan Unix offers production systems with advanced soldering methods that provide a high-speed quality soldering solution for automotive, medical, aerospace and electronics manufacturers. The company offers a wide range of soldering robots with a strong competency in precision soldering and factory automation.