MYDATA will present and demonstrate new refinements to its jet printing technology at Productronica 2013 that address the growing need for high-speed add-on application of solder paste among electronic manufacturers.

The popularity of jet printing technology to apply solder paste to printed circuit boards is growing fast as more and more electronics manufacturers understand the key advantages over traditional methods of solder paste application, such as screen printing or dispensing. Today hundreds of electronic producers worldwide are using jet printing for a diverse range of applications – situations that demand speed, design freedom and high-quality solder joints.

A surge for jet printing

Recently, MYDATA reports a surge of interest in jet printing from high-volume manufacturers as an alternative to classic dispensing technology for solder paste applications. The company says the growing interest in jet printers is largely attributable to their higher speed as well as the very high quality and consistency of the solder paste deposition that the MY500 gives. Today, needle dispensing is a common method for the selective application of solder paste on both populated and unpopulated boards. “I think what many manufacturers are realizing is that there are limitations in terms of speed, robustness and reliability, particularly in higher throughput environments,” says Nico Coenen, Global Sales Director Jet Printing. “As jet printing is roughly three to five times faster than dispensing there are better alternatives,” he continues.

Superior to dispensing

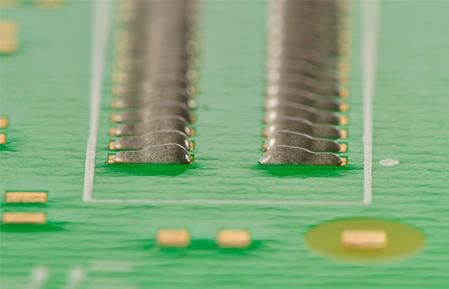

Unlike dispensing, jet-printing is a non-contact technology where the nozzle “flies” above the board ejecting solder paste, ensuring highly accurate volume repeatability of deposits. It also encompasses benefits with no Z-movement and automatically compensates for board warpage and stretch. Solder paste is acknowledged being a very difficult media to dispense. However, jet printing of solder paste has a preset of parameters that guarantees a stable production process over time. In addition a fully software-driven approach gives total control and capability for the manufacturer to optimize solder paste volume and shape ensuring the highest quality solder joints.

Meeting demand for speed

“A growing number of high-volume players are realizing that jet printing can dramatically speed up their in-line assembly for add-on applications following the screen printer, since this is the fastest way to apply paste on pre-printed boards,” says Nico Coenen. With the addition of low-temp pastes, too, he points out that common challenges such as repair and shield mounting can now be overcome at the speeds demanded by high-volume manufacturers.

For more information on MYDATA’s MY500 Jet Printer, please stop by the Productronica show in Munich, Germany (Nov. 12 – 15, Booth A3 241).

Micronic Mydata AB is a Swedish high-tech company engaged in the development, manufacture and marketing of production equipment to the electronics industry. The products consist of pattern generators including mask writers and direct writers for the production of photomasks and substrates as well as advanced surface mount technology (SMT) equipment. The pattern generators are used by the world’s leading electronics companies in the manufacture of semiconductor circuits, for advanced electronic packaging and displays used in PC tablets, smart phones, TVs and computers. The SMT equipment is used for surface mounting of electronic components and stencil free jetting of solder paste. The SMT equipment is used, among others, by large and small manufacturers of electronics in aerospace, aviation and telecom. Micronic Mydata headquarters is located in Täby, north of Stockholm and the Group has subsidiaries in China, France, Germany Japan, Singapore, South Korea, Taiwan, the Netherlands, United Kingdom and the United States. For more information see our web site at: www.micronic-mydata.com