The productronica is an important trade fair for LPKF Laser & Electronics AG. In time for the opening, the specialist in micro-material processing presents four new systems and procedures.

"Nearly 20 percent of LPKF’s workforce is engaged in research and development. This ensures our technological leadership and expands our product portfolio," this is how CEO Dr. Ingo Bretthauer explains the product offensive of the engineering company situated in Garbsen, Germany. At the productronica in Munich from November 12th through 15th, LPKF will present new products from different business areas.

LPKF ProtoMat D104

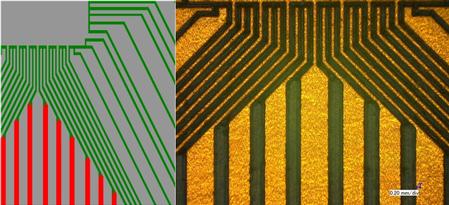

A spectacular new development is the ProtoMat D104. ProtoMats are circuit board plotters which carve circuit tracks out of fully coated base materials by negative contour routing. They are able to change tools automatically and to do contour milling or to drill PCB vias. The new ProtoMat D104 is upgraded with an additional special tool: a laser extends the processing range to special sensitive materials and allows structures down to the ultra fine pitch. Depending on the material, the laser structures with a pitch of 100 microns (50 microns line / 50 micron space) in-house. Ceramics can also be processed using the laser tool.

Since the laser is only used for sensitive or very fine structures, the ProtoMat D104 combines the precision of the laser with the mechanical skills of a highly developed milling/drilling system. The ProtoMat D104 is designed for operation in ambitious laboratories and development environments.

LDS prototyping

3D-circuit carriers have gained considerable market share in recent years, especially in the antenna technology, and have opened new product categories. 3D plastic components with circuitry can now be found also in the automotive industry, medical technology and in LED design. The laser direct structuring (LDS) has the largest share in this success.

One of the barriers was the time-consuming and costly prototyping for installation trials and functional tests. LPKF now offers a consistent procedure and the related systems which ideally allow LDS prototyping within a day.

To create the basic component, a conventional 3D printer is used. The LDS coating is performed by a special 2 component paint. At productronica, LPKF launches the ProtoPaint LDS in a spray can, which replaces the former method of the spray gun. The advantage of the new solution: one thorough coating is usually sufficient to apply the LDS layer. Formerly, three to four passes were required.

The activation of the component is done by the new ProtoLaser 3D. It has a large, height-adjustable working platform and a laser optic, which corresponds to the ones used in production systems. Therefore, the ProtoLaser 3D can be used for series-like 3D rapid prototyping and also serves well for process optimization. The ProtoLaser 3D is based on the proven ProtoLaser concept, where the working chamber is housed vibration-decoupled in a compact body.

The third step for LDS Prototyping is the metallization: LPKF ProtoPlate LDS consists of an ergonomically designed housing with the necessary technology and separately to be process chemicals ProtoPlate CU. ProtoPlate CU is delivered. ProtoPlate CU is delivered as a package with all necessary consumables.

First, the metallization bath is brought to process temperature in the ProtoPlate system, then the pre-portioned activator is added. The structured components are suspended in this bath. Depending on the duration, copper layers build up between 3 microns and 15 microns. No chemistry knowledge is required for this process.

Fusion3D 1200

The production side of the LDS technology is also growing. The Fusion3D 1200 is optimized for server operation and supports the loading-/unloading process by a rotary table. This LDS system can be used for small, medium and large series and may be upgraded with up to three laser sources.

MicroLine 2000 family

Not only has the appearance been changed, but the inside as well. With the MicroLine 2000 family, LPKF shows a new generation of laser systems for the separation of bare and assembled, rigid and flexible PCB materials. These PCB processing systems can be ordered with different laser powers. A faster fiducial registration and the optimized dynamics are guaranteed for a faster machining process. The advanced machine software facilitates the setup of production processes with high variance.

The new LPKF MicroLine 2820 SI is inline-capable and can be integrated directly into the production line thanks to a SMEMA interface.

Application specialists on site

For the first time, the application specialists of the Plastic Welding division are also represented. They will show, with examples from the automotive industry, how to fix PCBs without mechanical stress in plastic housings and protect them against environmental influences afterwards.

All LPKF systems will be exhibited at the main booth 105 in hall B2. At Essemtec in Hall 3 Booth 341 a LPKF Fusion3D 1100 laser structuring is presented in conjunction with an automatic 3D assembly.

LPKF Laser & Electronics AG manufactures machines and laser systems used in electronics fabrication, medical technology, the automotive sector, and the production of solar cells. Around 20 percent of the workforce is engaged in research and development.