Printable, formable conductive inks that can be applied to a flat plastic substrate and then molded into various shapes offer exciting new opportunities to engineers and designers trying to incorporate internal electronic circuitry into molded automotive and aircraft interior parts, as well as a wide variety of industrial and consumer electronic assemblies...

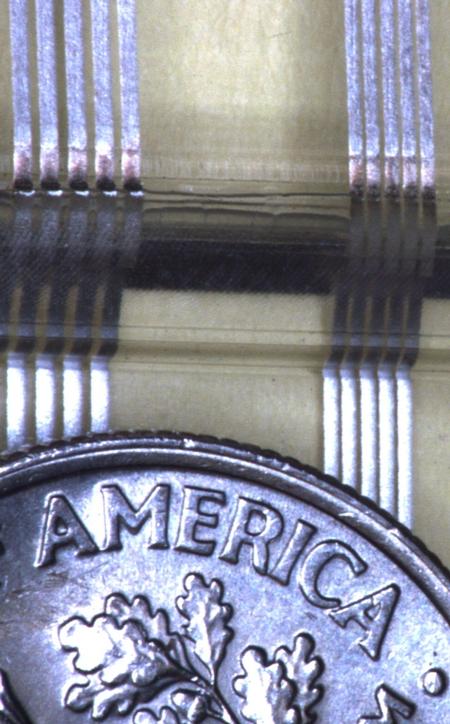

Conductive Compounds Inc., a Hudson, NH (USA) based manufacturer of specialty materials for printed electronics and electronic assembly industries, announces a new series of specialty conductive inks designed for plastic molding applications. These conductive inks can be printed onto flat plastic substrate films using conventional screen, gravure or pad printing techniques. After drying the inks, the plastic film can then be formed into shape using heat and pressure, and the printed conductive ink traces will follow the contour of the molded part. Even with sharp bends and deep draw sections in the molded part, the conductive ink traces will maintain conductivity. These new conductive inks allow design engineers to incorporate electronic circuit traces easily into molded parts, such as automotive interior components, without the additional manufacturing step of attaching a circuit to a molded part. Conductive Compounds Inc.’s moldable conductive inks have been used to fabricate antennas on automotive bumpers for proximity sensors where the molded parts incorporated deep draw sections up to four inches (10 cm) deep without losing significant electrical conductivity in the printed antenna. The new inks can provide improved construction and more efficient production of moldable parts which were not previously possible.

“Conductive Compounds Inc. is committed to offering engineered functional ink products to meet the demands for new or improved printed electronic technology worldwide, and the moldable conductive ink series is an exciting new addition to our expanding portfolio of products” notes Don Banfield, Product Manager of Conductive Compounds Inc. “ These moldable inks offer design engineers options

to incorporate circuitry in products without having to rely on attachment of other materials to a molded part. The benefits of cost reduction, reduced weight, lower profiles and new design options in molded assemblies are extremely attractive”

All Conductive Compounds Inc.’s R&D and manufacturing are done in the USA at its Hudson, NH facility. Typical product lead time is two weeks depending on volume. For information on Conductive Compounds Inc.’s full line of inks and adhesives visit: http://www.conductivecompounds.com.

Conductive Compounds Inc., founded in 1994, is a worldwide provider of materials for the electronics industry. It specializes in electrically conductive and resistive inks and coatings, electrically conductive and thermally conductive adhesives, potting compounds, ultraviolet-cured dielectrics, encapsulants and conformal coatings, radio opaque inks, silver and silver chloride inks, PTC (Positive Temperature Coefficient) carbon heater inks, VRI (Variable Resistance Inks) mechanical abrasion resistant precision carbon inks and pressure sensitive variable resistance transducer inks. CCI’s materials are used to manufacture membrane switches, EL (Electroluminescent) panels, touch screens, EKG and EEG medical sensors, cell phone and RFID (Radio Frequency Identification) antennas, rigid and flex circuits, printed heaters, solar panels, and for EMI/RFI (Electromagnetic Interference/Radio Frequency Interface) shielding and thermal management of electromechanical assemblies. The company specializes in custom developing products for unique applications and backing its products with unsurpassed technical support and customer service. For further information call 603-595-6221 or visit www.conductivecompounds.com.

.gif)