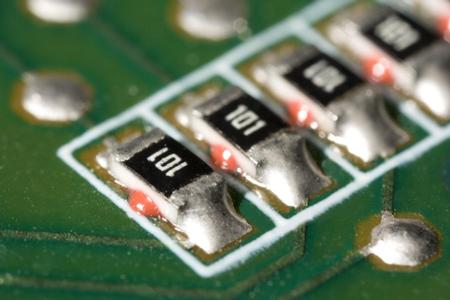

Known worldwide for surface-mount adhesive (SMA) development leadership, Henkel has set the industry benchmark with its high-performance Chipbonder brand adhesives. Within the company’s expansive portfolio of SMAs is LOCTITE 3621, which has been validated for use with non-contact dispensing – often referred to as jetting – technologies. This capability makes the SMA even more ideal for high-volume production environments.

The majority of SMAs are needle dispensed which, although adequate for many applications, does have limitations in terms of speed, as well as dot shape and size. LOCTITE 3621’s unique rheology makes it well-suited for non-contact dispensing processes, which helps alleviate some of the drawbacks with traditional needle dispensing. Using LOCTITE 3621, non-contact dispense speed is nearly four times faster as compared to needle dispense techniques. With a small dot size (350µ/0.014” and larger), dots per hour (DPH) of up to 40,000 can be achieved with non-contact dispensing as compared to an average of 10,000 DPH with alternative methods.

“Though LOCTITE 3621 can be utilized in either traditional needle dispensing or non-contact dispensing systems, customers are increasingly migrating to higher throughput options,” notes Tom Adcock, Henkel Electronic Materials Global Product Manager for Assembly Adhesives. “The speed and dot consistency available with LOCTITE 3621 allows higher yields at faster production rates – which are often the metrics of operational efficiency.”

In addition to its sheer speed advantage, LOCTITE 3621 non-contact dispensing SMA also provides for more uniform dot dimensions and volume repeatability. Needle dispense techniques are often prone to tailing or stringing, which can result in contamination of the solder pads and, ultimately, a poor interconnect. Non-contact dispensed LOCTITE 3621 eliminates this concern, as it there is no tailing or stringing, dot dimensions are more spherical and dot to dot consistency is far better as compared to alternative deposition methods. Other notable advantages of LOCTITE 3621 include the material’s lead-free wave compatibility, excellent green (wet) strength, fast cure capability of 120 seconds at 150°C and long shelf life of one month at room temperature and ten months under refrigerated storage conditions.

“Consistent with Henkel’s innovation philosophy, LOCTITE 3621 delivers high performance in a supremely adaptable and cost-effective material system,” concludes Adcock. “With this material, speed and strength are not mutually exclusive!”

For more information on LOCTITE 3621 or any of Henkel’s next-generation Chipbonder SMAs, log onto www.henkel.com/electronics or call the company’s customer and product support center at

1-888-943-6535.

Henkel operates worldwide with leading brands and technologies in three business areas: Laundry & Home Care, Cosmetics/Toiletries and Adhesive Technologies. Founded in 1876, Henkel holds globally leading market positions both in the consumer and industrial businesses with well-known brands such as Persil, Schwarzkopf and Loctite. Henkel employs more than 47,000 people and reported sales of $21.7 billion and adjusted operating profit of $2.8 billion in fiscal 2011. Henkel’s preferred shares are listed in the German stock index DAX and the company ranks among the Fortune Global 500.