The iTAC.MES.Suite Assures Transparency and Traceability in Electronics Manufacturing For Small & Medium - Sized Companies

Increasing product variance and shorter product lifecycles have become the norm for manufacturers of electronic products and EMS providers. Small to medium-sized enterprises in particular find themselves under increasing pressure to remain innovative. iTAC Software AG provides SMEs with a Manufacturing Execution System (MES) that enables them to optimize their manufacturing procedures and react flexibly to new market requirements.

The growing complexity of electronic components, frequent software updates and the ongoing emergence of new technologies are the determining factors in the electronics industry. Only those enterprises that are capable of adapting quickly to meet new customer requirements and changing processes, while at the same time producing premium-quality goods, will be able to remain competitive in the long term.

The goal is to manage short process and cycle times. This leads to improved delivery times, reduced storage risks, greater supply reliability, faster order processing and consequently a better service, to name just a few of the benefits.

Organisation instead of administration

Maximum possible workflow transparency and process stability are the basic prerequisites for achieving efficiency targets. Deploying the iTAC.MES.Suite allows companies to control all the relevant parameters and optimize them accordingly. Control mechanisms not only support faster processes and optimised services, they also enhance the quality of products and components. The status of manufacturing processes can be reviewed at all times, while the iTAC.MES.Suite assures traceability and with it a seamless record of the complete manufacturing process. The targeted, systematic and early identification of deviations and weaknesses significantly reduces failure rates. This puts managers in a position where they are not only capable of administering processes, but also of dynamically influencing them.

Quality instead of quantity

Hence the iTAC.MES.Suite provides both major enterprises and SMEs with a Manufacturing Execution System that provides them the capability to bring new products to market in record time and to produce even more premium-quality variants of sophisticated products, even in small quantities.

Further information will be available to interested visitors to the iTAC booth (No. 135, Hall A3) at the “Productronica” trade fair being held in Munich on November 15-18.

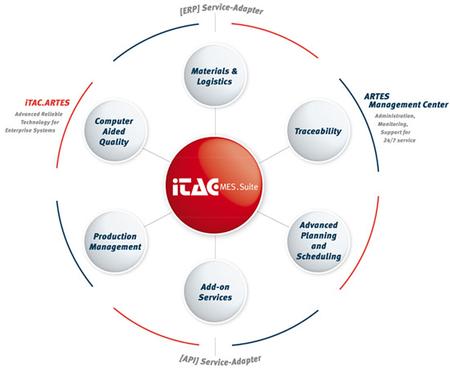

iTAC Software AG is a system and solution provider specializing in Manufacturing Execution Systems (MES) with an effective production philosophy. In accordance with this philosophy, iTAC develops, integrates and maintains its platform-independent iTAC.MES.Suite for manufacturing enterprises around the world. The software facilitates considerable quality improvements along the entire process and production chain up to zero defect production. The service architecture comprises a comprehensive range of functions such as Traceability, Production Management, Advanced Production Scheduling, Computer-Aided Quality and Material Logistics, plus add-ons. As a result of its high level of standardisation and technological basis, the iTAC.MES.Suite can be used for practically all factory manufacturing operations. iTAC Software AG is headquartered in Germany and has branch offices in France, the USA and China.