In this newsletter, we describe the exciting new features XYZTEC has incorporated in its latest Condor Sigma software release. Customers are recommended to upgrade, so they can benefit from all the new free features. The advanced Halcon fiducial recognition and SECS/GEM may require additional licences.

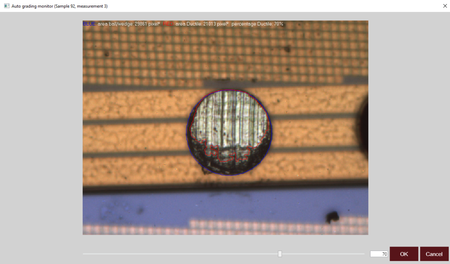

Automatic grading and advanced image processing

One of the most exciting additions in version 5.8 of the Condor Sigma software is automatic grading for ball shear testing. Using the advanced Halcon library and high resolution perpendicular cameras with smart lighting systems, we have achieved successful determinations of failure modes for several customers. The computer can accurately determine the percentages of brittle and ductile failures.

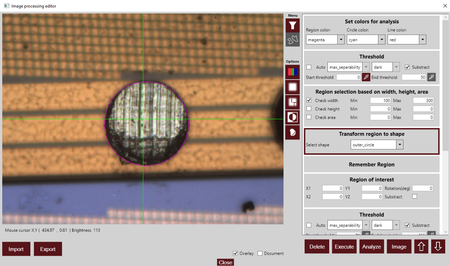

The same library is also used for advanced fiducial recognition for applications that have difficult and inconsistent fiducial marks or where no fiducial marks exist enabling other features to be used. The advanced shape recognition features of Halcon allow engineers to use separate color channels and several image filters. Image segmentation techniques can help to further isolate the unique features that the engineer is interested in. The result can be used as the basis for positioning correction (for example wire detect).

Several small changes to the status bar make the software easier to work with. For example, it is now possible to change the working position and selected camera by a simple click.

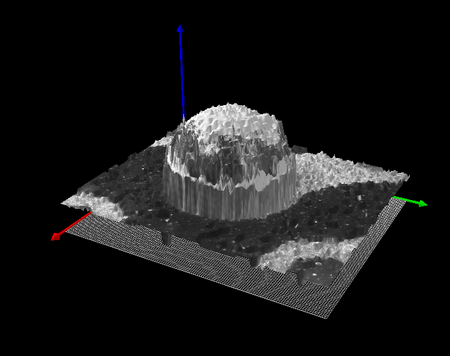

Composite Surface Imaging

Using composite surface imaging techniques, it is possible to accurately determine the heights of a feature on your sample. This can be used for multiple purposes, like determining loop heights without actually touching the wire. It is also possible to produce images wherein everything is in focus.

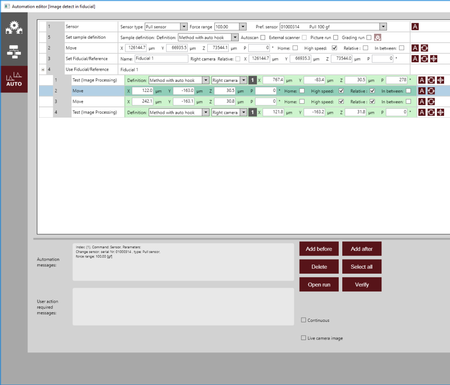

Execute fiducials while programming

The programming of an automation sequence just got a whole lot easier, with the possibility to execute fiducials during programming. Even if the sample has slightly moved or is replaced with a different sample, running the fiducials from the editor will ensure that added or changed test positions and commands are correct.

Automation programming can now be done from the tool position or either of the camera systems on your Sigma. Another improvement is that it is now possible to check fiducials against multiple photos so that failed recognitions during the automation runs occur less often.

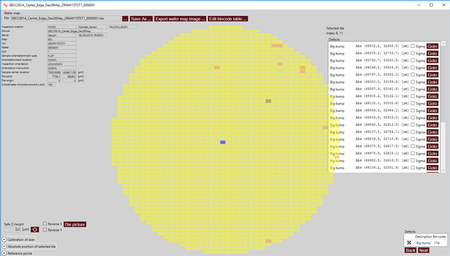

Wafers and EFEM interface

Several small and large improvements were made for wafer testing. Among other things, version 5.8 provides enhanced support of wafer tables with vacuum detect sensors. The engineer also gets more flexibility when working with the patented contactless CBP Jaw Cleaner. The standard cleaning process is improved and large wafer maps are displayed better and faster. Click here to see our latest W12 automation video.

SECS/GEM

SECS/GEM is an equipment interface protocol for equipment-to-host data communications in the semiconductor industry. Among other protocols, XYZTEC offers SECS/GEM communication directly in the Condor Sigma software or via an EFEM. Contact XYZTEC for more information and options for your factory.

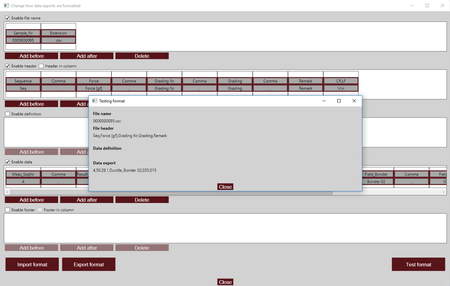

Data export editor and centralized database

A built-in export editor is introduced. This enables the engineer to create his own reports in almost any format, to be saved to a file or the clipboard.

The Condor Sigma software also has improved networking support. Multiple bond testers can now share a centralized database. In close cooperation with our customers, we made sure it is possible to share certain settings while keeping others machine specific.

If you would like to use these new functions or would like additional information, do not hesitate and contact us to request a demonstration, bond testing seminaror a quotation.

Upgrade to 5.8 now

Click here to download Condor Sigma software version 5.8 and upgrade now. Contact your local XYZTEC distributor to assist you if required.

If you are interested in a live demonstration of the Condor Sigma on your sample or perhaps for more bond testing inspiration, please contact us today!

References are available and happily provided.