YUSH Electronic Technology Co.,Ltd

YUSH Electronic Technology Co.,Ltd was founded in 2004,is located in the world manufacturing city Jiangsu,Guprofessional pcb separator/pcb depanelizer electronic equipment machinery. The company has

YUSH Electronic Technology Co.,Ltd Postings

57 products »

Automatic PCB depaneling V-cut PCB Depanelizer Machine Lowest cutting stres pcb depaneling

Features: For the automatic pcb cutting equipment developed for the COB light source board, the microcomputer is used to control the automatic feeding board. Suitable for PCB board, aluminum substrate, copper board slit...

Multiple Groups Of Blades PCB Depaneling Machine PCB Dividing Equipment LED Cutting

High quality PCB depaneling machine / V-cut PCB depanelizer,multi-blade depaneling machine,Pcb Separator Feature 1. The shaft of the knives( top and bo...

700 X 800 X 950mm 0.05mm Precision Hot Bar Soldering Machine Automatic Soldering Robot

700 X 800 X 950mm 0.05mm Precision Hot Bar Soldering Machine Automatic Soldering Robot Equipment operation description...

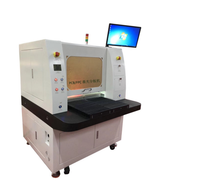

355nm 10W /15W High-precision CCD FPC/PCB UV Laser Cutting Machine

355nm 10W /15W High-Precision CCD FPC/PCB UV Laser Cutting Machine With Perfect CAM interface, it supports the mainstream of the drilling and milling file format; man-mach...

0.6-5.0mm thickness V Groove PCB Depanel Machine/PCB Board Separating Machine

0.6-5.0mm Thickness V Groove PCB Depanel Machine/PCB Board Separating Machine Blades Moving PCB Separator Fe...

0.6-5.0mm thickness V Groove PCB Depanel Machine/PCB Board Separating Machine

0.6-5.0mm Thickness V Groove PCB Depanel Machine/PCB Board Separating Machine Blades Moving PCB Separator Fe...

800KG 450*450mm Automatic QR Code Coding Machine Introduction PM series continuous automatic inkjet printer adopts high te...

60000r/Min Online PCB Depaneling Router With Visual Correction Function

60000/min 300mm*350mm Automatic Visual Online PCB Depaneling Router/pcb depaneling machine Product Description: 1. The PCB...

0.1mm-0.5mm Desktop Multiple Blades PCB Depaneling Machine / Moving Blade Type PCB Separator

0.1mm-0.5mm Desktop Multiple Blades PCB Depaneling Machine / Moving Blade Type PCB Separator Product Description:: YSATM-3L COB fi...

330×220mm 930×880×1750mm PCB/FPC/LED Punching Machine

330×220mm 930×880×1750mm PCB/FPC/LED Punching Machine YSPE PCB/FPC Punching Machine Feature:...

2 technical articles »

Fully automatic online shoe sole and upper spraying robot

May 23, 2019 | Peter Chen

Automatic on-line shoe sole spraying system: automatic shoe sole spraying system, simple and convenient operation, using 3D vision positioning system. Automatic recognition and automatic generation of spraying trajectory. Robot non-contact spraying gun is used to complete the process of shoe sole spraying with maturity, stability, high speed and high precision along the predetermined trajectory. The automatic generation of spraying trajectory is the realization of shoe sole spraying technology. Shoe sole spraying characteristics: 1.Positioning System: 3D Visual Positioning 2.Components: Intelligent Robot, Laser Scanner, Industrial Computer, Gum Spraying System, Conveyor Belt, Electrical Control System, etc. 3.Spraying time: slightly different according to shoe size and spraying time Fully automatic sole spraying advantages: 1. Simple application: suitable for soles of different specifications, models and sizes 2. Faster speed: 6-8 seconds to complete sole scanning and spraying, superior to similar products at home and abroad. 3. Quality stability: gum spraying trajectory is scheduled, gum dosage is fixed, gum spraying quality is greatly improved. 4. High cost performance: the same performance, the price is only 1/3 of the same type of equipment of European brand. 5. Reduce wear and tear: glue is fully utilized and not wasted, reducing human contact with glue. Intelligent operation advantage manual only need general operation can be automated workshop, mechanical arm automatic spraying glue, accurate spraying, reduce glue waste. Environmental protection effect of long-term close contact with glue seriously affects human health and mechanical work, glue does not directly contact, do not harm the human body. Fully automatic spraying, shoe sole adhesion process for automatic spraying machine, will not cause great challenges! With the deepening of personalized shoemaking, higher requirements have been put forward for the spraying technology in shoemaking process. The method of creating spraying trajectory must be adapted to shoes of different sizes and styles. The automatic generation of spraying trajectory is one of the key technologies to realize the automation of shoe sole spraying process. The method of off-line programming and real-time generation of spraying trajectory for robots based on the three-dimensional CAD model of sole and the data of sole. A new method of generating spray trajectory by scanning the sole of shoe upper with linear structured light sensor is presented. The feasibility of the method is verified by industrial robots. Aiming at the need of generating shoe sole spray rubber trajectory based on line structured light, the format standard of IGES file of three-dimensional model of shoe sole was tested. The shoe sole contour line and the shoe sole surface were extracted, and then the offset curve of the shoe sole contour line on the shoe sole surface was calculated to obtain the spray rubber trajectory. Three-dimensional profilometer is to use structured light to obtain sole information, effectively improve the automatic shoemaking spraying process, which will help to improve the efficiency of shoemaking, improve the quality of footwear products, and promote the development of personalized shoemaking....

three knives led strips cutting machine

May 13, 2019 | Peter Chen

For the customers of LED lamp industry, LED board splitter is indispensable. Our machine is cheap, light weight and cutting speed is 500 mm per second. email:s1@hk-yush.com...