Kapp Eco-Babbitt Spray Wire for Capacitors

Company Information:

Name: |

Kapp Eco-Babbitt Spray Wire for Capacitors |

Category: |

|

Offered by: |

|

Kapp Eco-Babbitt Spray Wire for Capacitors Description:

Kapp Eco-Babbitt coatings are applied to capacitors as a protective coating;

• To shield against electromotive force (EMF) and electromagnetic interference (EMI) with the specified performance of the capacitor;

• To prevent current and charge leakage out of and within the layers of the capacitor;

• To prevent the development of electron flows within the coating material itself, thereby diminishing capacitor performance and coating and capacitor life.

COMPOSITION MELTING RANGE°F MELTING RANGE°C

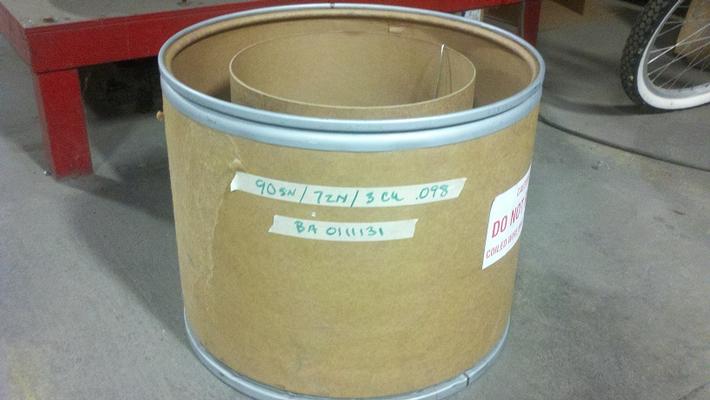

90Sn-7Zn-3Cu 392 – 432 200 – 222

Kapp Alloy developed the proprietary Precision Microcasting™ process specifically to address the adverse effects of segregation during billet and wire formation:

1. Excessive spray head wear and clogging,

2. Excessively wide temperature requirements due to inconsistent alloys,

3. Excessive wire breakage due to inconsistent alloys,

4. Improper coating deposition due to inconsistent alloys,

5. Current and charge buildup due to inconsistent alloys.

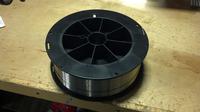

Our proprietary Precision Microcasting™ process forms the wire directly from the molten alloy. The wire cools extremely quickly, maintaining a precise alloy from edge-to-edge and end-to-end through thousands of pounds of wire. In addition, several production steps have been eliminated to increase production efficiency and decrease potential errors and defects.

In addition to process variables affecting segregation, the greater the zinc content the greater the possibility of segregation in the billet and wire. This increased segregation is avoided in Kapp Alloy’s Precision Microcasting™ process by forming the wire directly from the molten alloy and cooling it quickly and consistently.

Call 800-327-6533 or e-mail will@kappalloy.com for a quote. RFQ number 130

Kapp Eco-Babbitt Spray Wire for Capacitors was added in Apr 2013

Kapp Eco-Babbitt Spray Wire for Capacitors has been viewed 3547 times

20 More Products from Kapp Alloy & Wire, Inc :

.gif)