Designing flex and rigid flex for manufacturability

Company Information:

Name: |

Designing flex and rigid flex for manufacturability |

Category: |

|

Offered by: |

|

Designing flex and rigid flex for manufacturability Description:

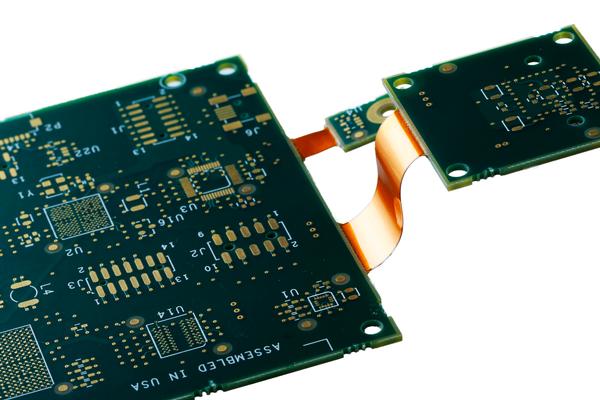

Designing Flex and Rigid-Flex Applications

Duration: 90 minutes

Abstract: Of course they bend and can be formed, but did you know that flexible circuit boards are lighter weight, more durable and more cost effective than a rigid board or wiring harness? Used in an ever-growing wide-variety of end applications, flexible circuit boards offer demanding industries such as military, medical, aerospace and industrial numerous benefits.

Please join us for a lunch and learn session to find out more about designing flexible circuits.

Presenter: Circuits, LLC President, Adeodato Vigano

Agenda:

• Intro to Flex circuits (benefits discussion, properties, advantages)

• Compare/Contrast to FR4 rigid design

• Types of Flex

• Assembly considerations (panelization, arrays, stiffeners, fixtures)

• Design considerations (best practices for reliability and manufacturability, specifications, plating finishes, materials, and more)

• Specifications

About Circuits:

Circuits, LLC is a quality-driven, customer-focused manufacturer of highly reliable built-to-spec flexible printed circuit boards serving the defense, industrial, and medical markets with consistent quality and on-time delivery unsurpassed by competitors.

Circuits, was founded in 2008 by veteran PCB engineering and fabricating professionals united by a common vision of better, more adaptable PCB manufacturing and support service. Operating out of a modern, $2 million, 30,000 square foot facility, the shop was designed specifically for flexible PCB manufacturing. Central to the operation is a Class 1000 clean room that houses all imaging processes to ensure the highest quality in-process printed and photosensitive materials. The mechanical and wet processes surround the clean room to create a highly efficient work flow within the manufacturing area.

Contact Lori Vidra, Vice President Sales and Marketing, for more information on Circuit’s Flex Seminars.

lvidra@circuits-corp.com

724-519-4773

Designing flex and rigid flex for manufacturability was added in Nov 2014

Designing flex and rigid flex for manufacturability has been viewed 848 times