Contract PCB Assembly

Company Information:

Name: |

Contract PCB Assembly |

Category: |

|

Offered by: |

|

Contract PCB Assembly Description:

STI is equipped with a state of the art 26,000 sq ft manufacturing area with the latest in high speed placement, inspection, and test equipment in addition to work cells to assemble complex box builds. Our personnel are uniquely qualified to assemble to the highest quality standards and are all trained and certified to J-STD-001 ES (Space Addendum). This includes all technicians, machine operators and support personnel.

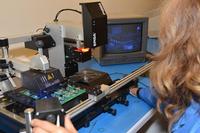

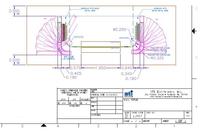

Placement capability includes surface mount high speed placement of components down to 01005 in size. Our Juki FX-3 and KE2080-L pick and place machines offer placement rates that can compete with any contract manufacturer. Inline and secondary automatic optical inspection (AOI) ensures in-process control for placement accuracy of components. STI’s reflow operation is performed in a 13-zone oven to ensure proper profile and temperature ramp (± 2°/s) to eliminate thermomechanical overstress due to wide variance in thermal exposure. This is especially critical on large, fine-pitch devices (e.g. BGAs, etc). Additionally, high speed through-hole component processing is available using our Juki selective solder machine which automates through-hole soldering for higher volume applications.

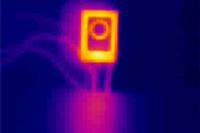

At STI, product quality is our top objective. All processes are governed by a quality system certified to ISO 9001-2008 with manufacturing and inspection in accordance with IPC J-STD-001 ES. All completed assemblies are washed and visually inspected after each process. BGA devices are 100% X-RAY inspected, and X-RAY images are available upon request. Flying probe testing is available to detect any opens and shorts on the assembly as well as to provide statistical analysis for device tolerances. Final inspection and packing is performed by IPC-certified inspectors with 10+ years in past performance experience with critical hardware.

STI has 20+ years in past performance building mission-critical Class III circuit card assemblies (CCA). Documentation of past performance and references are available upon request.

Contract PCB Assembly was added in Apr 2016

Contract PCB Assembly has been viewed 937 times

18 More Products from STI Electronics :