VT-X750 In-Line Automated X-Ray CT Inspection

Company Information:

Name: |

VT-X750 In-Line Automated X-Ray CT Inspection |

Category: |

|

Offered by: |

|

VT-X750 In-Line Automated X-Ray CT Inspection Description:

High-speed Automated X-ray CT Inspection System

The Omron VT-X750 is the perfect solution to manufacturers desiring the highest-speed, in-line, automated 3DCT X-Ray inspection on PCBs containing components such as BGAs or CSPs with hidden solder joints. Traditional AOI technology is incapable of inspecting these types of components but the VT-X750 uses revolutionary, high-precision, X-Ray imaging to perform precise and reliable analysis of these hidden areas and free of PCB design constraints.

The VT-X750 is capable of inspecting solder quality on a full-range of components from BGAs, leaded devices, chips and through-hole devices. Inspections are performed very quickly at speeds as low as 3 seconds per field-of-view (fov).

By using 3D reconstruction software and laser displacement technology, the VT-X750 gauges the PCB surface for each solder-joint, compensating for any warpage and allows the system to perform cross-sectional analysis at the proper slice-level locations.

Selectable resolutions of 6, 8, 10, 15, 20, 25 and 30 microns combined with selectable numbers of X-Ray projections (up to 512) allow for user-driven variation between higher inspection speeds for production environments to ultra-high quality 3D image acquisition for research and defect analysis.

- High-Precision, 3D CT X-Ray Imaging

- Fast and Accurate Automated Inspection

- Ultra-Low Dosage X-Ray Exposure

- User-Friendly Software and Interface

- Full Offline Program Generation

- Automatic Component Model Creation for Quick and Easy Programing

- Real-Time Process Monitoring

- Defect Checking Terminal and 3D Image Reviewing Software

- Data Analysis and Quality Control Software Tools

- Safe and Secure X-Ray Operation

- Omron's World Class Service and Support

Design constraint free

Dense and dual sided board design can provide challenges for X-Ray inspection.

However, Omron's 3D-CT technology can overcome such design restraints.

Zero down time

To achieve “Zero down time” during the SMT production process, OMRON supports machine operation globally by preventative maintenance, emergency support and machine monitor with remote access.

In-line full inspection coverage

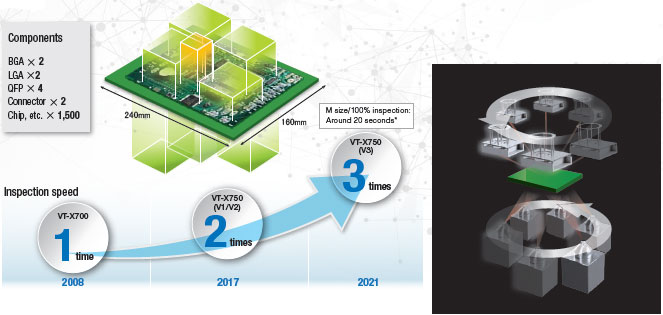

The VT-X750 improves upon previous Omron 3D-CT technology making it the fastest X-Ray inspection system to date *1.

The automated inspection logic has been improved for many parts such as IC heal fillets, stacked devices (PoP), through hole components, press-fit connectors, and other bottom terminated parts.

Increasing automated inspection speed and expanding inspection logic enables full, in-line inspection coverage by 3D-CT method.

*1. By an internal investigation in October, 2017.

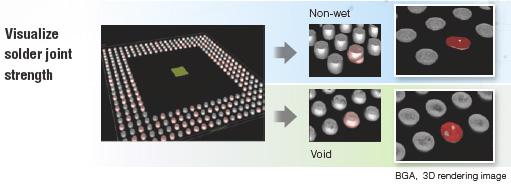

Visualize solder joint strength

OMRON’s unique 3D-CT reconstruction algorithms provide excellent solder shape recognition and defect detection.

Quantitative analysis allows for an automated inspection process which minimizes the risk of escapes while providing fast and repeatable operation.

Global Support

More than 30 locations.

VT-X750 In-Line Automated X-Ray CT Inspection was added in Oct 2016

VT-X750 In-Line Automated X-Ray CT Inspection has been viewed 1920 times

8 More Products from Omron Inspection Systems :